Antibacterial mold-resistant PVC (Poly Vinyl Chloride) flexible composition and preparation method thereof

An antibacterial and antifungal agent and composition technology, which is applied in the field of PVC soft composition and its preparation, can solve the problems of easy discoloration of silver ions and application restrictions, and achieve high antibacterial and antifungal efficiency, good stability, and excellent production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

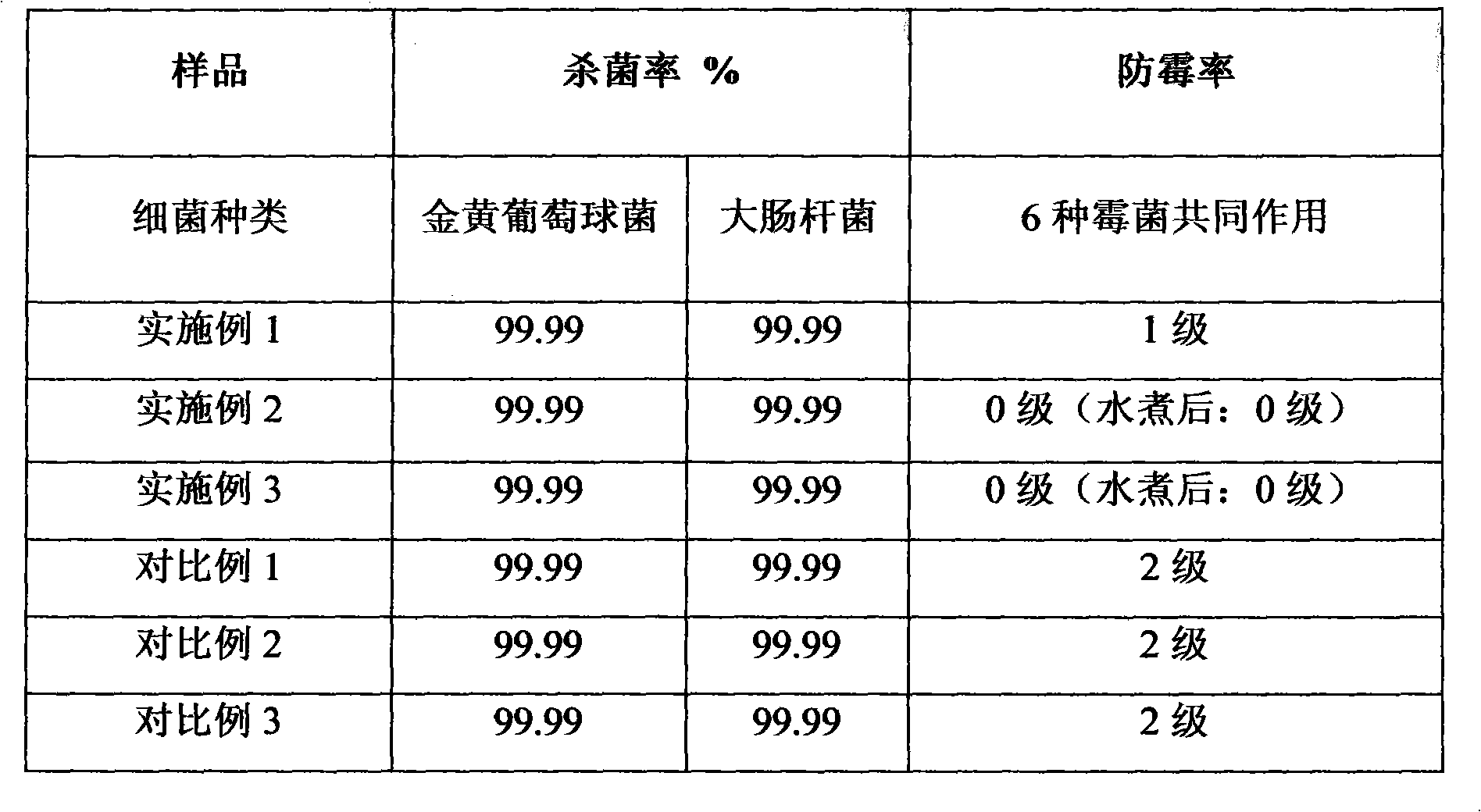

Embodiment 1

[0041]100 parts (by mass) of PVC powder (Hangzhou Denhua Group, DH-2500), 3 to 5 parts of calcium-zinc heat stabilizer (Kaimisen Company, product grade: 5515), 0.4 parts of internal lubricant calcium stearate (Tianjin Yongchangsheng Chemical Co., Ltd., industrial grade), 0.1 part of external lubricant polyethylene wax (Beijing University of Chemical Technology Fine Chemical Factory, LPE-F), put it into a high-speed mixer, stir at a high speed until 65 ° C, and then pour it slowly Add 100 parts of plasticizer-DOP (fine chemical plant of Beijing No. 4 Chemical Factory, chemically pure) to make PVC completely absorb the plasticizer. Stir at high speed until the temperature reaches 105°C and discharge. The PVC that has absorbed the plasticizer is cooled and stirred or placed at normal temperature, and then mixed with 0.6% (based on the whole PVC blend system) antibacterial and antifungal agent 1 and 30 parts of powdered nitrile rubber P83 (French Ilio company, acrylonitrile conten...

Embodiment 2

[0044] Put 100 parts (parts by mass) of PVC powder, 3 to 5 parts of calcium zinc heat stabilizer, 0.4 part of internal lubricant calcium stearate, and 0.1 part of external lubricant polyethylene wax into a high-speed mixer, and stir at high speed until 65°C, slowly pour 100 parts of plasticizer (DOP) at this time, so that PVC can completely absorb the plasticizer. Stir at high speed until the temperature reaches 105°C and discharge. Cool and stir the PVC that has absorbed the plasticizer or place it at room temperature, then mix it with 1% antibacterial and antifungal agent 1 and 30 parts of powdered rubber P83 at room temperature.

[0045] Mastication is carried out using a two-roll mill. Weigh the pre-swelled PVC material and put it into the double-roller open mill, thin pass plasticization, the resin film is passed through the rollers, dropped on the plate, and then passed through the rolls and placed on the plate, repeat this thin pass process until the rubber material is...

Embodiment 3

[0047] Put 100 parts (parts by mass) of PVC powder, 3 to 5 parts of calcium zinc heat stabilizer, 0.4 part of internal lubricant calcium stearate, and 0.1 part of external lubricant polyethylene wax into a high-speed mixer, and stir at high speed until 65°C, slowly pour 100 parts of plasticizer (DOP) at this time, so that PVC can completely absorb the plasticizer. Stir at high speed until the temperature reaches 105°C and discharge. Cool and stir the PVC that has absorbed the plasticizer or place it at room temperature, then mix it with 1% antibacterial and antifungal agent 2 and 30 parts of powdered rubber P83 at room temperature.

[0048] Mastication is carried out using a two-roll mill. Weigh the pre-swelled PVC material and put it into the double-roller open mill, thin pass plasticization, the resin film is passed through the rollers, dropped on the plate, and then passed through the rolls and placed on the plate, repeat this thin pass process until the rubber material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap