Ultraviolet light curing colored paint and preparation method thereof

A technology of ultraviolet light and color paint, applied in the field of coatings, can solve the problems of no adhesion, poor adhesion, and increased difficulty of HIPS materials, and achieve excellent leveling, good spraying effect, and reduced equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The UV-curable colored paint of the present embodiment, its formula and preparation method are as follows:

[0059] (1) Mix 2 grams of 1-hydroxy-cyclohexyl-phenyl ketone, 2 grams of 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone and 1 gram of 2,4,6 -Tritoluoyl diphenylphosphine oxide and 20.5 grams of diluent (ethyl acetate: butyl acetate: methyl ethyl ketone: isopropanol = 50: 20: 10: 20, mass ratio) are mixed under stirring, and the mixer presses 300 rpm, stirred for 5 minutes to a transparent liquid, and obtained a solution containing a photoinitiator;

[0060] (2) Add 10 grams of HDDA, 10 grams of TPGDA and 8 grams of TMPTA to the solution containing the photoinitiator prepared in step (1), and stir for 3 minutes at a stirring speed of 300 rpm until a transparent liquid is obtained. Mixture 1;

[0061] (3) Add 35 grams of multifunctional aliphatic urethane acrylate, 5 grams of modified epoxy acrylate and 3 After the addition of 1 gram of thermoplastic acrylic acid,...

Embodiment 2

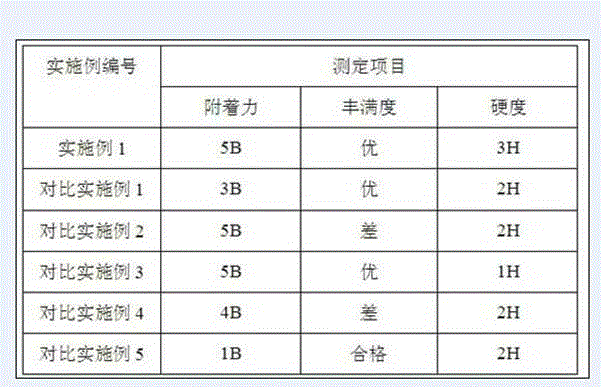

[0087] Embodiment 2 performance test

[0088] Spray the UV-curable color paint prepared in Example 1 and the UV-curable color paint prepared in Comparative Examples 1-5 respectively on the plastic casing of the TV, dry at 50-55° C. for 3-4 minutes, and then irradiate with ultraviolet light (The total absorbed energy value is 700-750 mJ / cm2), and the thickness of the paint film is 20-25 microns. Test the adhesion, construction appearance, fullness, hardness and UV color drying conditions of the cured paint film.

[0089]Adhesion test: use a scratcher to scratch 100 grids of 1 mm x 1 mm square on the surface of the paint film, stick it on the surface of the paint film with 3M adhesive tape, pull it up immediately at an angle of 45°, and observe whether there are scratches on the edge Shedding: if shedding is between 0-5%, it is 5B, between 5-10% is 4B, between 10-20% is 3B, between 20-30% is 2B, between 30-50% Between 1B and 0B above 50%.

[0090] Fullness: In a place with b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com