Improved structure of rapier machine

A rapier machine and yarn technology, which is applied in the field of rapier machines, can solve the problems affecting the weaving quality of fabrics, the adjustment effect needs to be improved, and yarn stretching and yarn skipping, etc., so as to reduce the proportion of product scrapping, low cost and good tension Moderating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

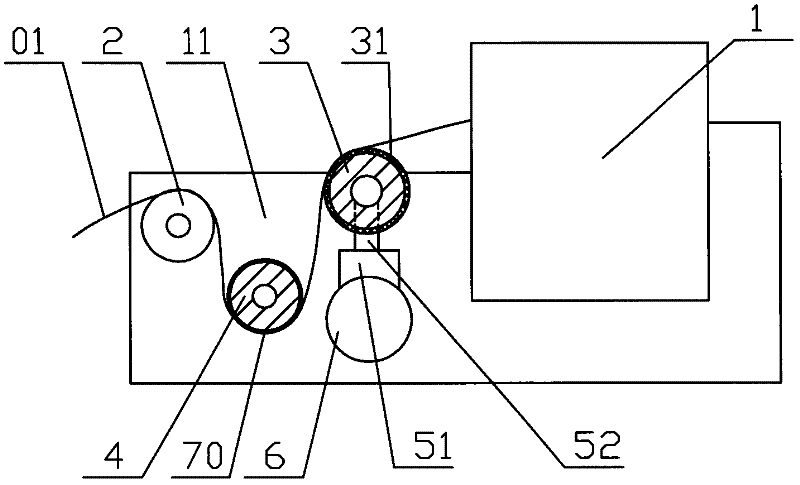

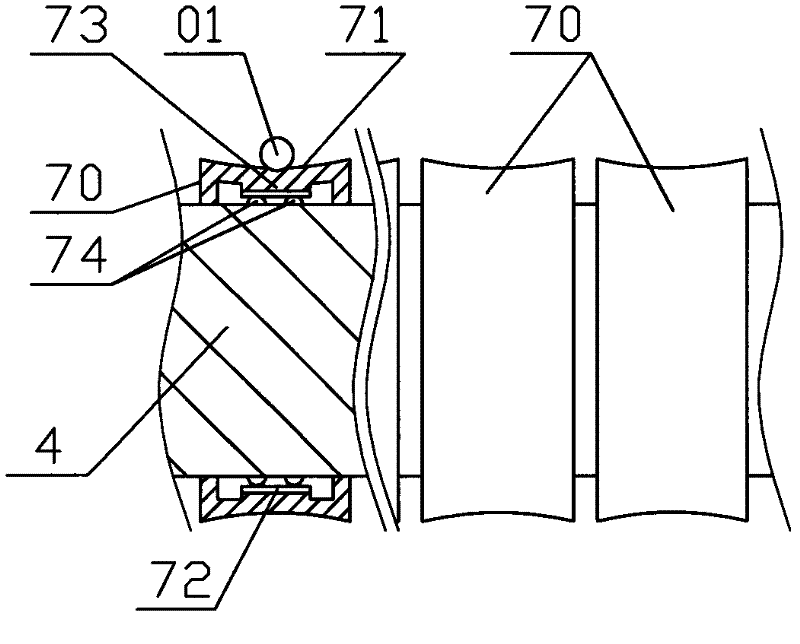

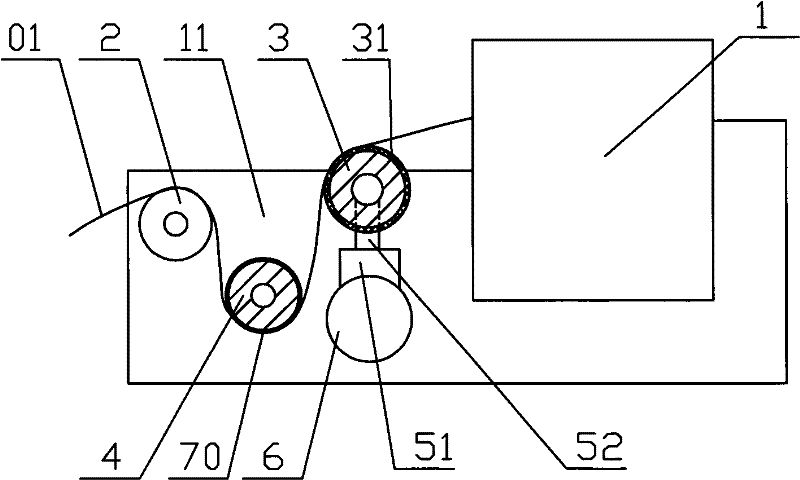

[0017] like figure 1 As shown, it is an improved structure of a rapier machine according to the present invention, which includes a rapier machine body 1, and a yarn tension adjustment device is provided on the yarn inlet side of the rapier machine body, and the yarn tension adjustment device includes a frame body 11, Yarn feeding guide roller 2 is arranged on the frame side near the yarn creel, regulating roller 3 is arranged on the yarn inlet side close to the rapier machine body, and intermediate roller 4 is also arranged between yarn feeding guide roller and regulating roller, and yarn 01 is sequentially After bypassing the yarn-entry guide roller, intermediate roller and adjustment roller, it is input from the upper end of the adjustment roller, that is, the upper end of the yarn-entry guide roller bypasses the lower end of the intermediate roller as shown in the figure, and then enters the rapier machine body from the upper end of the adjustment roller. The outer ring su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com