Active and passive adjustment combined thin film tensioning device

A tensioning device, active and passive technology, used in thin material handling, transportation and packaging, climate change adaptation, etc., can solve the problem of not meeting the requirements of film tension adjustment, unable to adjust film tension, and low tension adjustment accuracy. problem, to achieve the effect of good adjustment effect, simple structure and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

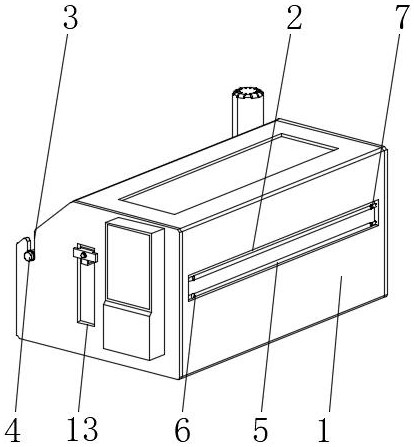

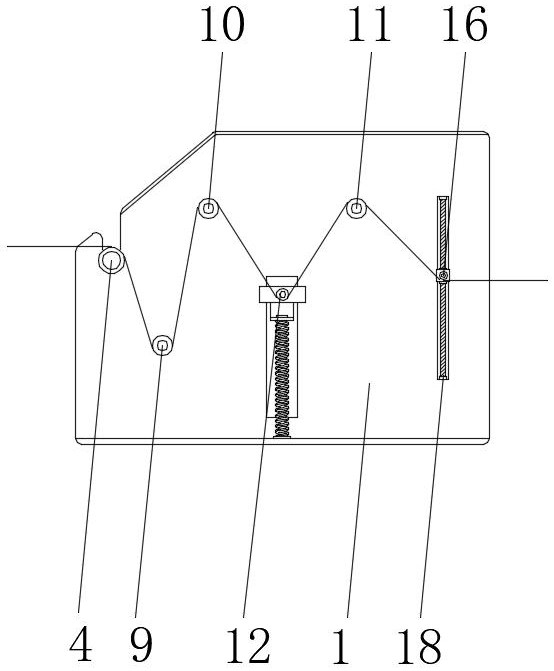

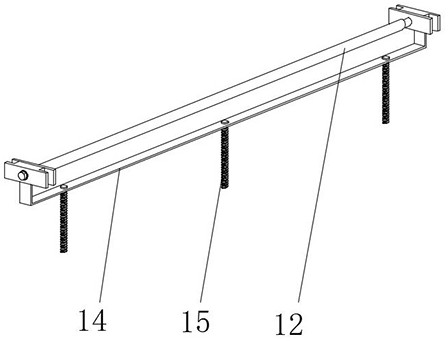

[0049] A film tensioning device combining active and passive adjustment, such as Figure 1-Figure 6 As shown, including device main body 1, tensioning assembly and film limit assembly,

[0050] The rear end surface of the device main body 1 is provided with an alarm assembly, the right end surface of the device main body 1 is provided with a film outlet 2, the left end surface of the device main body 1 is provided with an installation groove 3 near the upper end, and the inside of the device main body 1 is provided with a film guide assembly; The tension assembly is arranged inside the device main body 1, the tension assembly includes a passive adjustment assembly and an active adjustment assembly, the passive adjustment assembly is located on one side of the active adjustment assembly; the film limit assembly includes two sets of guide rollers 4, and the two sets of guide rollers 4 are respectively Installed on the installation groove 3 and film outlet 2;

[0051] Wherein, a...

Embodiment 2

[0071] On the basis of Example 1, such as Figure 1-Figure 6 As shown, this embodiment is the structure of the limit assembly,

[0072] The limit assembly includes two sets of limit pieces, and the two sets of limit pieces are installed on the outer surface of the guide roller 4 close to both ends;

[0073] The limiter includes a main body 6 and an adjusting cover 7 , both of which are sheathed on the outer surface of the guide roller 4 , and the outer surface of the main body 6 is connected to the inner surface of the adjusting cover 7 through threads.

[0074] The main body 6 includes a mounting ring, and the end of the mounting ring facing the adjustment cover 7 is fixedly installed with several groups of connection seats, and the several groups of connection seats are distributed in a ring. The end of the connection seat away from the installation ring is provided with a locking shrapnel 8, and the adjustment cover 7 is screwed on the main body. 6, the inner surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com