Dynamic balance tension traction mechanism and knitting machine with same

A technology of pulling mechanism and tension adjusting mechanism, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problem that each coil cannot be treated finely, the formed fabric cannot achieve the expected effect, and the coil of knitted fabric is bent. Deformation and other problems, to achieve the effect of easy replacement, good tension adjustment, and stable pulling tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

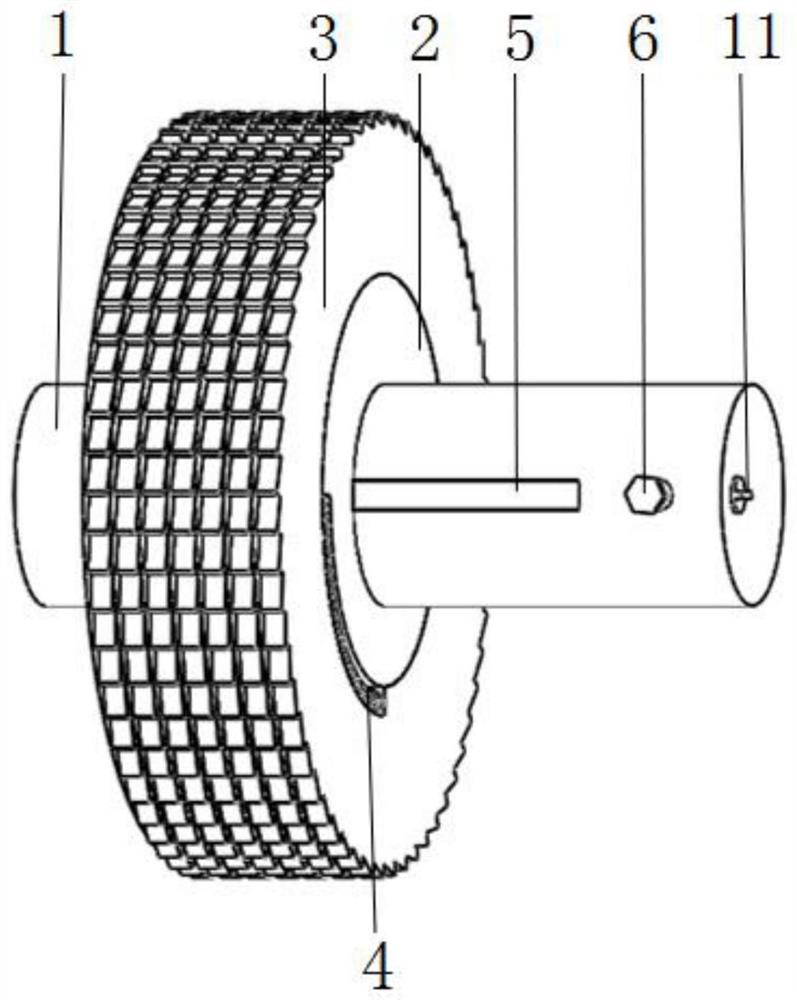

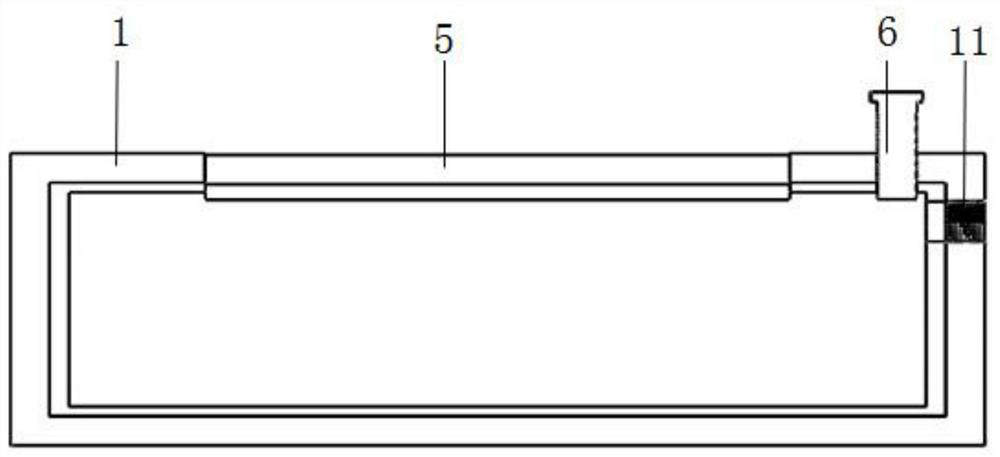

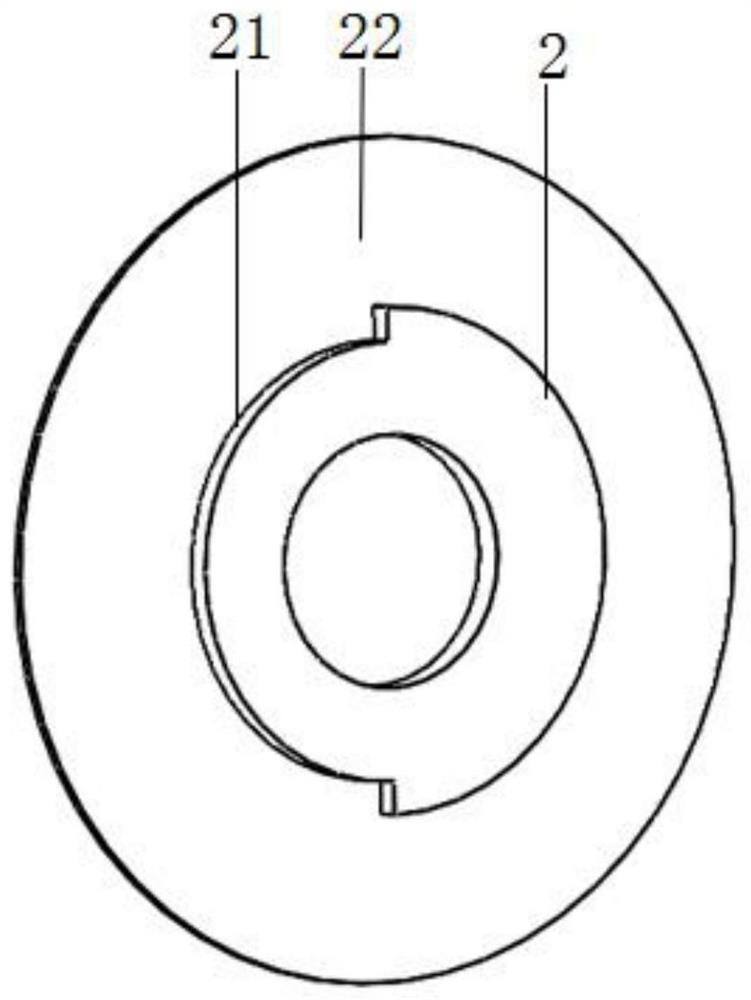

[0030] Such as figure 1 As shown, the dynamic balance tension pulling mechanism of this embodiment includes a rotary shaft 1, a tension adjustment mechanism, multiple sets of one-to-one corresponding transmission plates 2 and take-up wheels 3, the above-mentioned transmission plates 2 are set as discs, and the middle part is coaxial A shaft hole is provided, and multiple sets of the above-mentioned transmission pieces 2 are respectively sleeved on the above-mentioned rotary shaft 1. The above-mentioned tension adjustment mechanism is installed on the above-mentioned rotary shaft 1 and connected with multiple sets of the above-mentioned transmission pieces 2 for adjusting the above-mentioned transmission pieces. 2 and the balance of the rotary shaft 1, so that the above-mentioned transmission piece 2 is rotated in conjunction with the above-mentioned rotary shaft 1 or relatively rotated under the influence of external force, and the middle parts of the multiple groups of the abo...

Embodiment 2

[0050] This embodiment provides a knitting machine, including the dynamic balance tension pulling mechanism in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com