Tension adjusting device for warp knitting machine

A tension adjustment device and warp knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as yarn breakage and inaccurate detection, prolong service life, simple device structure, and improve production The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

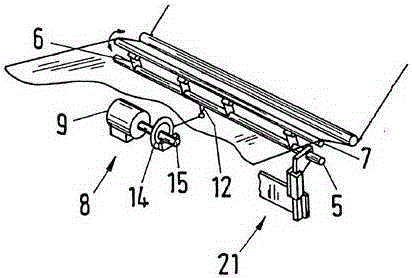

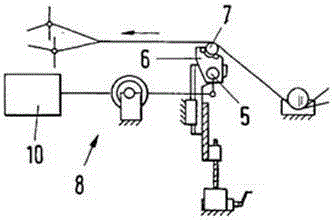

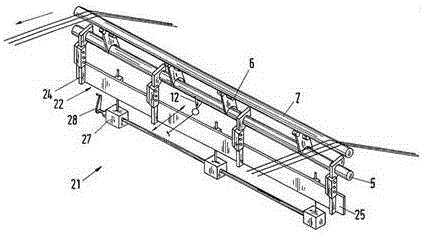

[0015] see figure 1 , figure 2 and image 3 , a kind of tension adjustment device for warp knitting machine, comprises tension frame, stand 21 and deflection driving device 8; and a plurality of support arms 6 between the tension roller 7; the stand 21 is hinged with the tension stand, and the stand includes a lifting adjustment device 22, and the lifting adjustment device 22 includes a horizontally arranged reinforcing beam 25, a plurality of worms Transmission device 27 and crank 28, the worm screw end of described worm transmission device 27 is fixedly connected with reinforcing beam 25, and described crank 28 drives worm screw transmission device 27 to adjust the height of tension frame in vertical direction, and described stand 21 also includes and A plurality of struts 24 vertically connected to the reinforcing beam 25, the multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com