Roller structure of computer controlled flat knitting machine

A flat knitting machine roller and computer technology, applied in weft knitting, knitting, textile and papermaking, etc., can solve the problems of insufficient pulling effect and poor applicability, and achieve the effect of taking into account the compactness and the increased pressure of the compression spring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by specific embodiment:

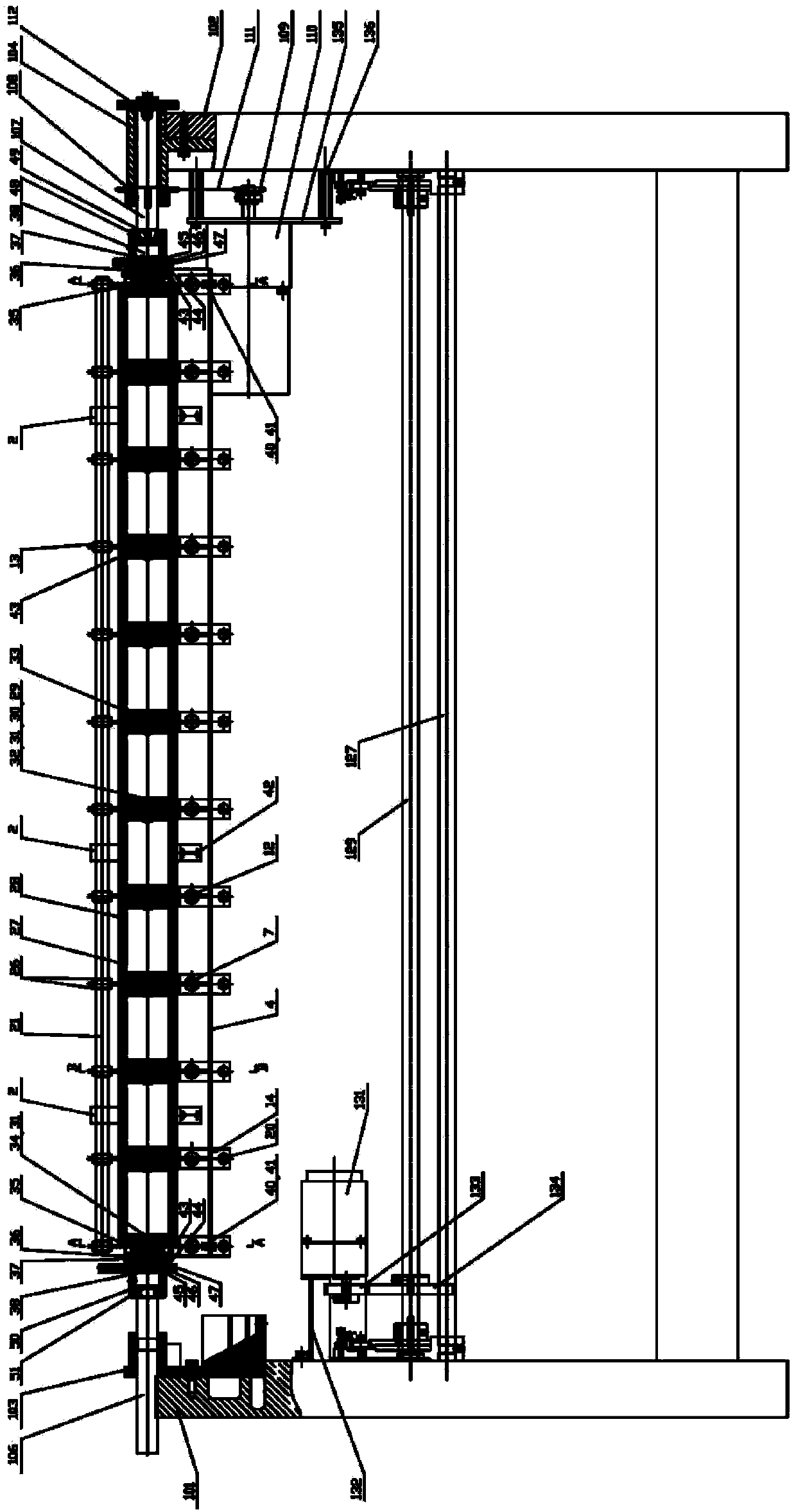

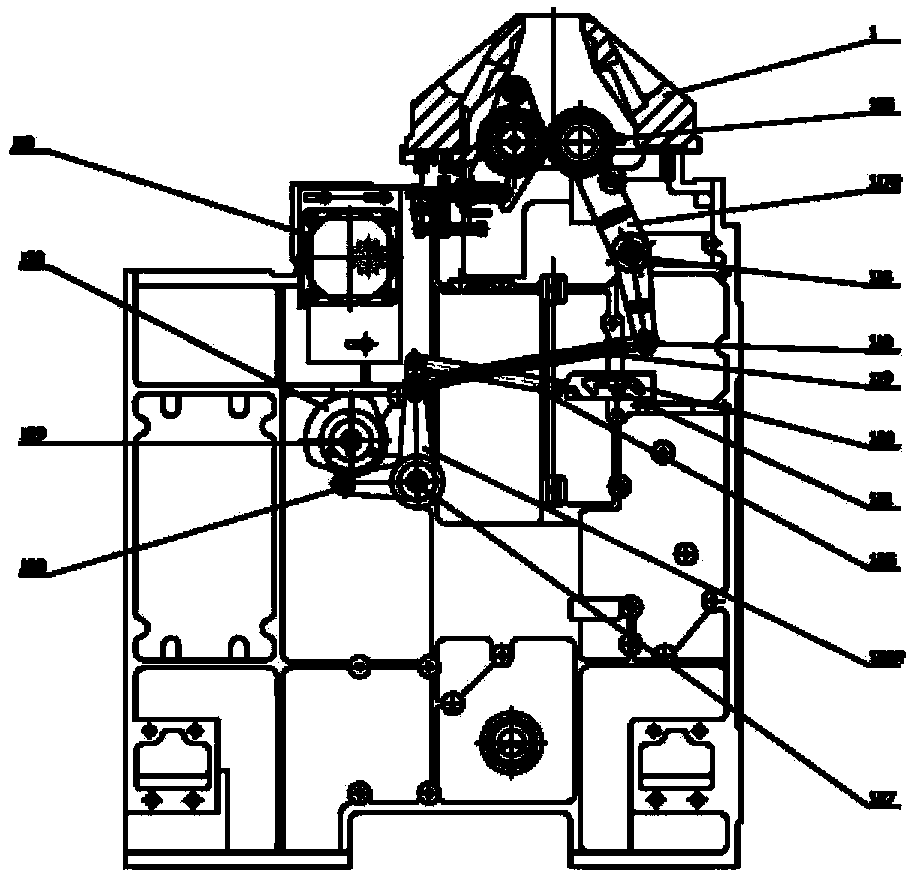

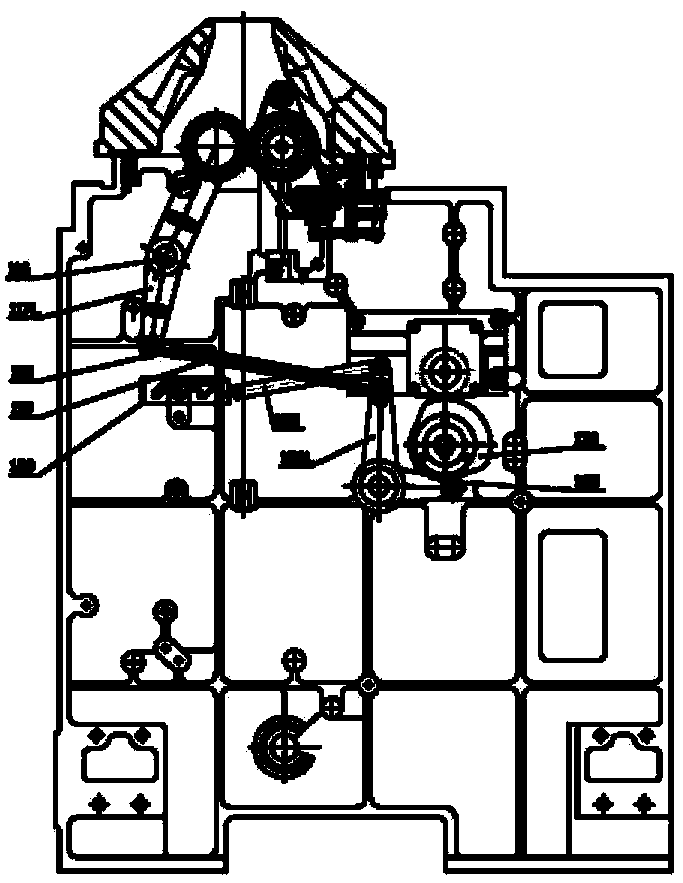

[0029] refer to figure 1 — Figure 7 , a computer knitting flat knitting machine roller structure, including a front roller 105F, a rear roller 105B, a support mechanism for fixing the front roller and the rear roller, a first torque motor 110 driving the rotation of the front roller and the rear roller, and controlling the closing of the front roller and the rear roller The second torque motor 131.

[0030] Roller transmission structure see figure 1 - Figure 4 , the left bracket 103 is installed on the left wallboard 101 of the frame, and the right bracket 104 is installed on the right wallboard 102 of the frame, figure 1 , 4 The rear roller 105B of the rear roller 105B is respectively installed on the supporting mechanism on the left wallboard 101 and the right wallboard 102 with the shaft 106 and the drive shaft 107, and the inner deep groove rolling bearing 43 center of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com