Lead-zinc battery

A storage battery, zinc negative charge technology, applied in the field of novel types of storage batteries, can solve problems such as cycle life limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

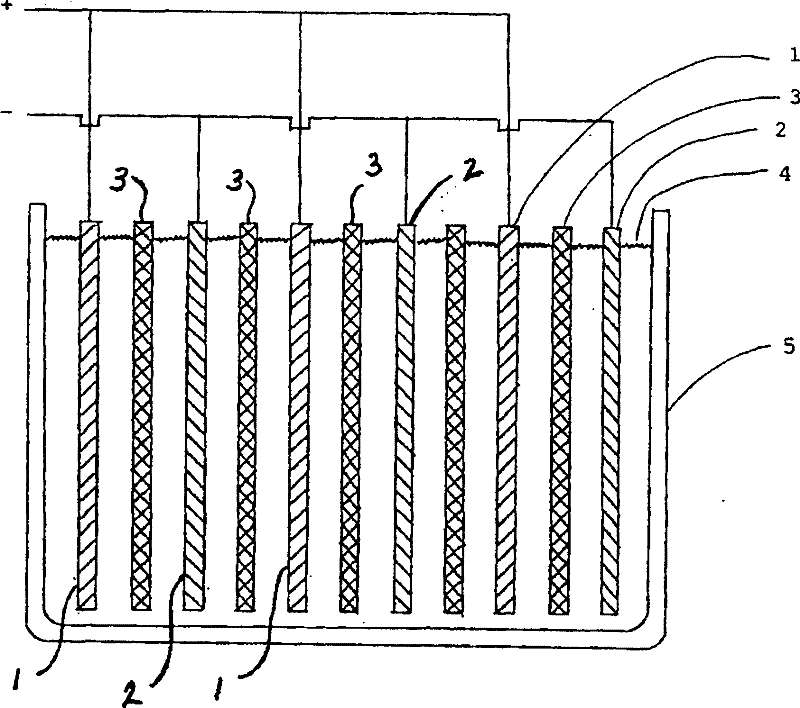

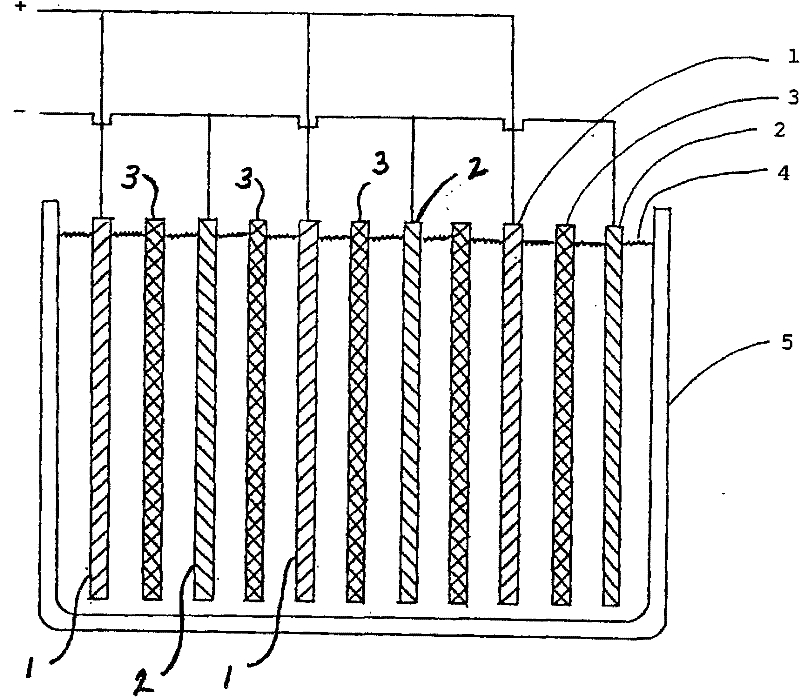

Image

Examples

example

[0027] (1) Make batteries out of glass jars 2.5" diameter x 4" high. Plastic spacers separate the electrodes. The positive electrode was a lead strip 1.5 inches wide and 4 inches high. The negative electrode was a strip of zinc 1.5 inches wide and 4 inches high. The electrolyte solution was prepared by dissolving 44.1 grams of at least 99.0% sodium sulfate in 200 milliliters of water. After charging the battery at 3.0 volts for 25 minutes, an open circuit voltage of 2.75 volts was observed. Discharge the battery through a loop containing the flash bulb, producing 95mA.

[0028] (2) The same battery as used in Example (1) was used. In this operation, an electrolyte solution was prepared by dissolving 45.1 grams of at least 99.0% lithium sulfate monohydrate in 200 milliliters of water. An open circuit voltage of 2.72 volts was obtained after charging the battery at 3.0 volts for 25 minutes. The battery draws 92 milliamps through the same circuit as used in example (1).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com