Rotor of high-efficiency and ultrahigh-efficiency three-phase asynchronous motor

A three-phase asynchronous, ultra-high-efficiency technology, applied in the field of motors, can solve the problems affecting the increase of motor output power, the cooling air flow direction is not very reasonable, and the cooling effect of the motor is low, so as to increase the volume and cost, improve the cooling effect, and flow direction reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

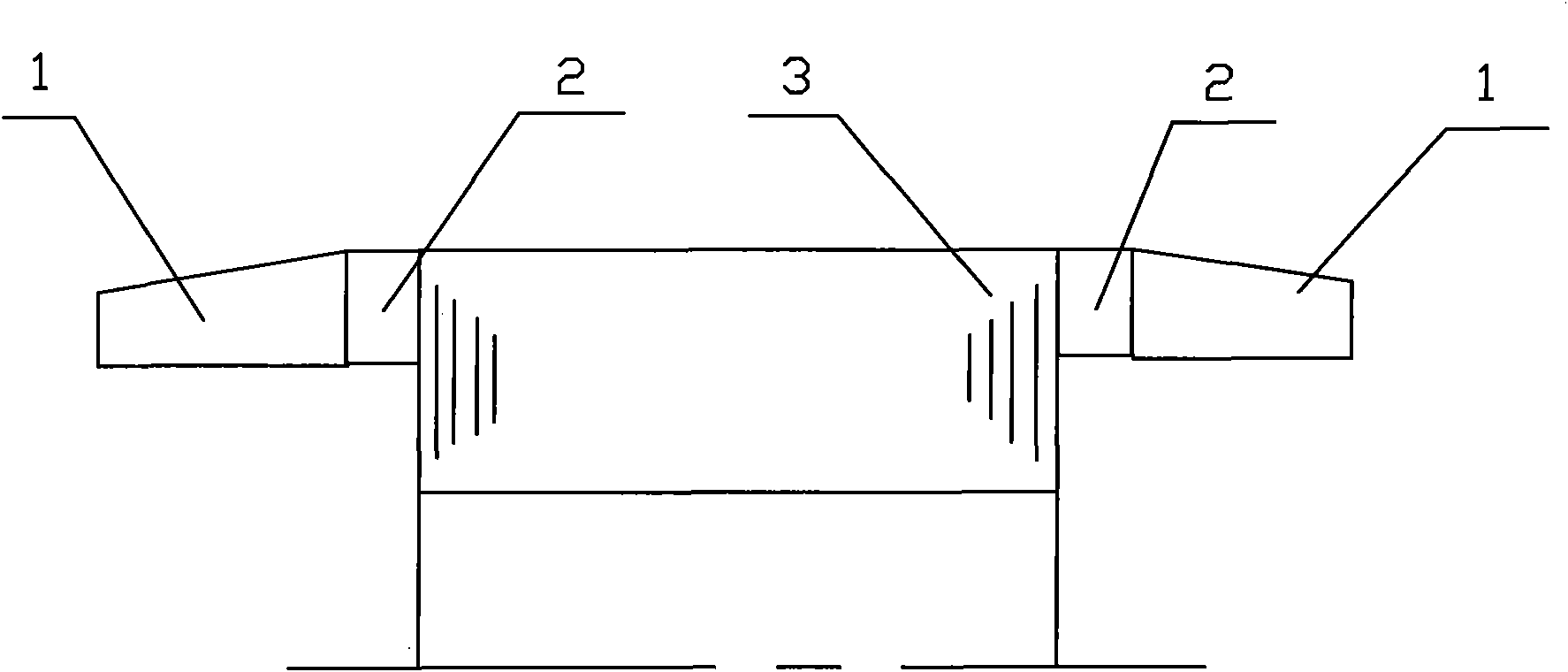

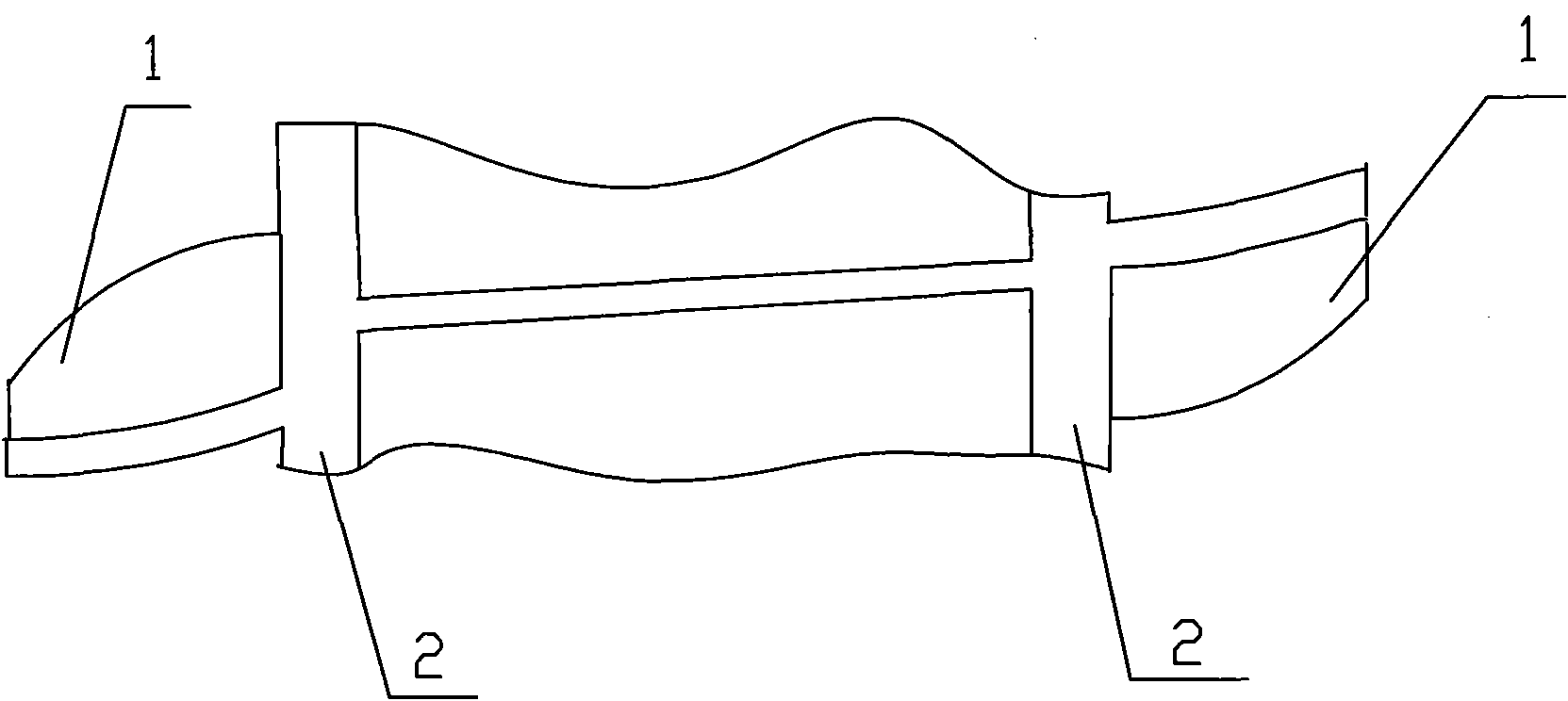

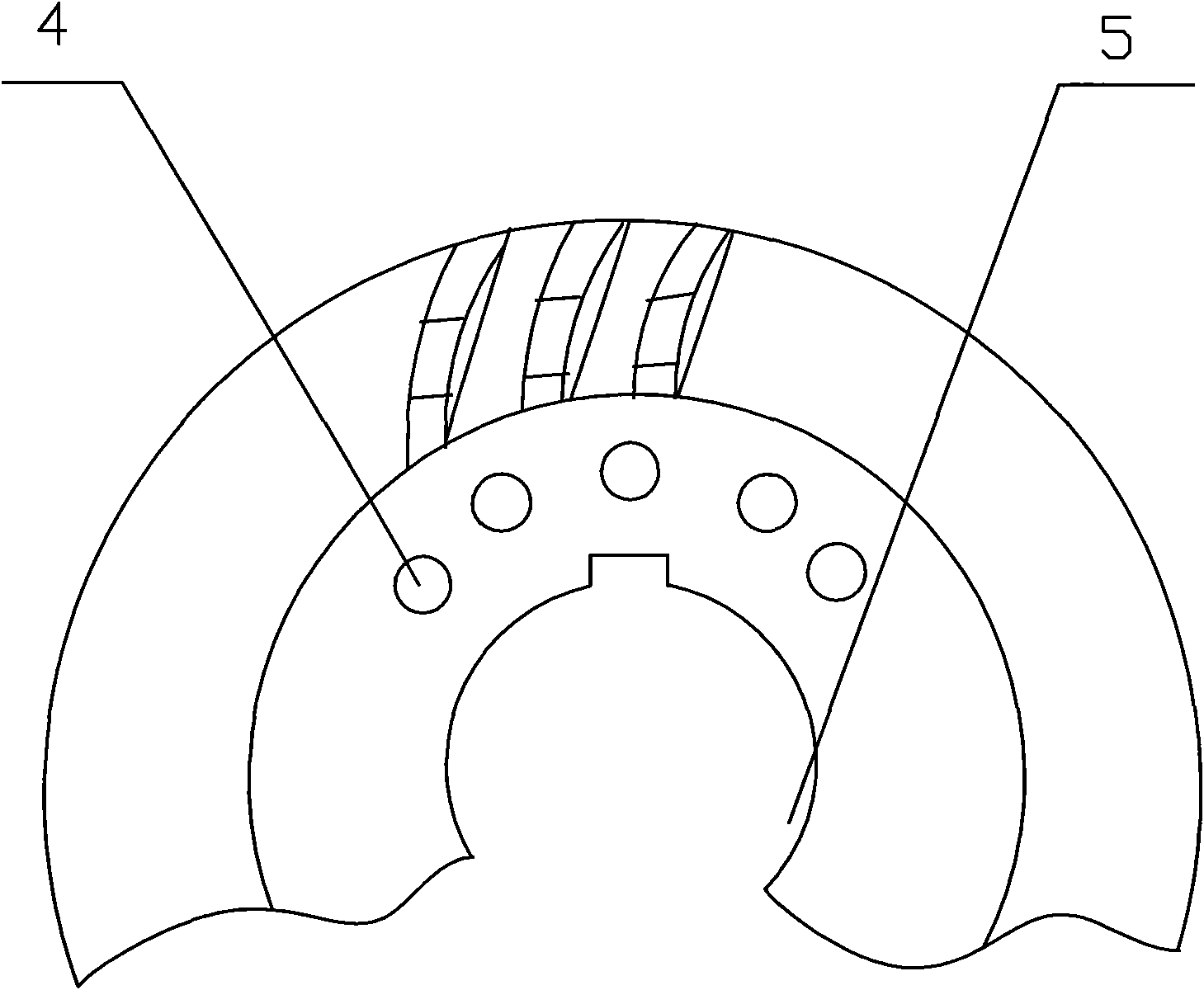

[0015] In order to better understand the technical solution of the present invention, the following specific examples in conjunction with the accompanying drawings figure 1 , figure 2 , image 3 Give a detailed explanation.

[0016] see figure 1 , figure 2 and image 3 , a high-efficiency, ultra-high-efficiency three-phase asynchronous motor rotor of the present invention comprises a rotor core 3, two cast aluminum end rings 2 at both ends of the rotor core, several fan blades 1 on the outer end faces of the two cast aluminum end rings, several Fan blades 1 are evenly distributed on the outer end surfaces of both ends of the cast aluminum end ring 2, and each fan blade is in the shape of a spiral arc.

[0017] The fan blade 1 and the cast aluminum end ring 2 are formed by cast aluminum casting in one body, and the fan blade 1 may also be a component fixed on the outer end surface of the cast aluminum end ring 2 .

[0018] The rotor core has a central shaft hole 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com