Method for improving mouldability and particle quality of traditional Chinese medicine formulation particles obtained by dry granulation

A technology of traditional Chinese medicine formula granules and dry granulation, which can be applied to pharmaceutical formulas, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., and can solve the differences in physical properties such as maltodextrin compressibility and hygroscopicity. , poor formability, poor solubility and other problems, to improve the spray sticking problem, good fluidity, and enhance the effect of anti-hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

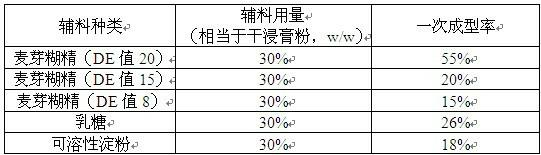

Image

Examples

Embodiment 1

[0030] Take 1000g of Trichosanthes extract powder, add 250g of maltodextrin with DE value of 20, mix evenly, granulate with roller dry press, and then mix evenly with 2.5g of micropowder silica gel. The one-time molding rate of the granules reaches 68%. The granules have good solubility, good taste, and good anti-moisture agglomeration ability.

Embodiment 2

[0032] Take 1000g of antler concentrate (20% solid content), add 30g each of maltodextrin and lactose with a DE value of 16, mix well, spray dry to obtain antler extract powder, granulate with a roller dry press, and then mix with micropowder Mix 1g of silica gel evenly. The one-time molding rate of the granules is up to 75%, the granules have good solubility, good taste, and good anti-moisture agglomeration ability.

Embodiment 3

[0034] Take 1000g of Morinda officinalis concentrate (solid content 20%), add 60g of maltodextrin with DE value 18 and 40g of maltodextrin with DE value 12, mix well, granulate with roller dry press, and then mix with micro powder Mix 2g of silica gel evenly. The one-time molding rate of the granules reaches 72%. The granules have good solubility, good taste, and good anti-moisture agglomeration ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com