Preparation method of instant bean flour rich in vitamin B12

A technology of instant soy flour and B12, applied in the field of food processing, can solve problems such as deficiency and poor absorption of vitamin B, and achieve the effects of high production efficiency, prevention of pernicious anemia, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

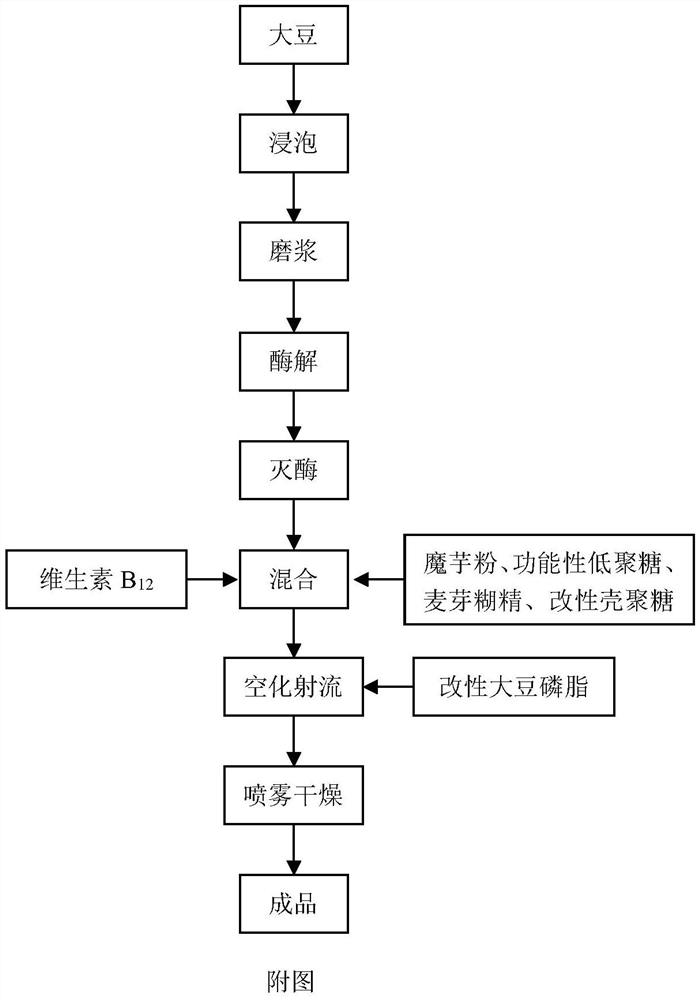

[0021] A rich vitamin B 12 The preparation method of instant bean powder, the method comprises the following steps:

[0022] (1) Take commercially available soybeans and add distilled water at a ratio of 1:5, soak for 12 hours, refine the pulp, and put them in a water bath for enzymolysis. The enzymolysis conditions are: enzymolysis temperature 55°C, enzymolysis time 2h, pH value maintenance At 9.0, the amount of flavor protease added is 0.2-0.6%, and after the enzymolysis is completed, boil for 5 minutes to kill the enzyme and sterilize;

[0023] (2) Weigh 1~5% (w / v) vitamin B 12 Powder, added to the soymilk after enzymatic hydrolysis, and then added konjac powder, functional oligosaccharides, maltodextrin, and modified chitosan in equal proportions to prepare;

[0024] (3) Use a cavitation jet homogenizer for processing, the processing conditions are: temperature 25°C, pressure 0.1MPa, processing time 20-40min;

[0025] (4) Add 0.3-0.9% modified soybean lecithin in the so...

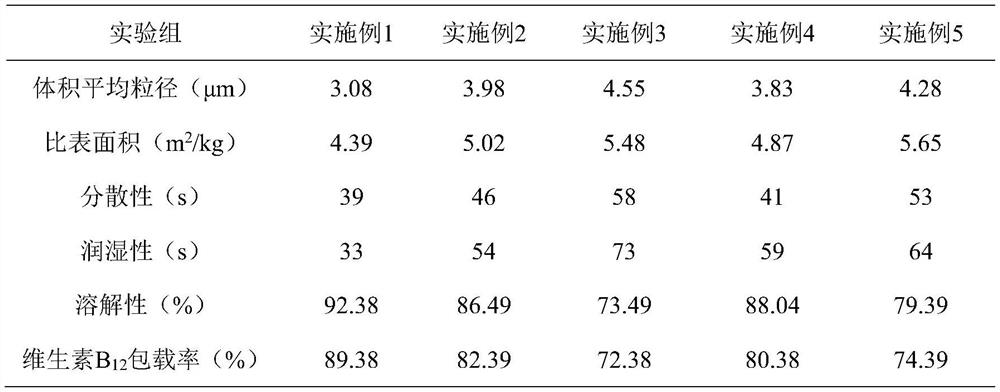

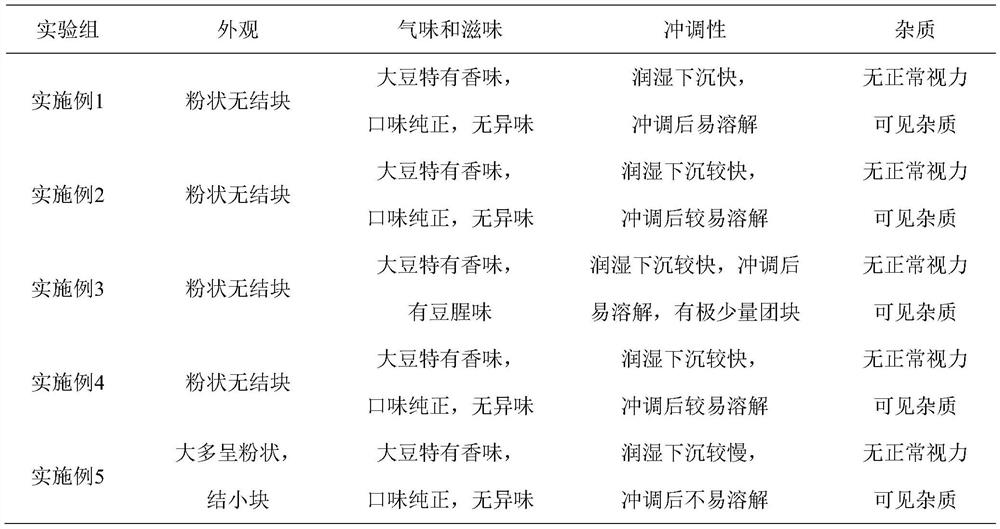

Embodiment 1

[0027] Embodiment 1: A kind of rich in vitamin B 12 The preparation method of instant soybean flour is characterized in that it comprises the following steps: (1) taking commercially available soybeans and adding distilled water in a ratio of 1:5, soaking for 12 hours, grinding, putting into a water bath for enzymolysis, and the enzymolysis conditions are: : Enzymolysis temperature is 55°C, enzymolysis time is 2 hours, pH value is maintained at 9.0, flavor protease is added at 0.4%, after enzymolysis, boil for 5 minutes to kill enzyme and sterilize; (2) Weigh 3% (w / v) vitamin B 12 powder, added in the soybean milk after enzymatic hydrolysis, and then added konjac flour, functional oligosaccharides, maltodextrin, and modified chitosan in equal proportions to prepare; (3) Utilize a cavitation jet homogenizer for processing, and the processing conditions are : temperature 25 ℃, pressure 0.1MPa, treatment time is 30min; (4) add 0.6% modified soybean lecithin in the solution, and ...

Embodiment 2

[0028] Embodiment 2: A kind of rich in vitamin B 12 The preparation method of instant soybean flour is characterized in that it comprises the following steps: (1) taking commercially available soybeans and adding distilled water in a ratio of 1:5, soaking for 12 hours, grinding, putting into a water bath for enzymolysis, and the enzymolysis conditions are: : Enzymolysis temperature is 55°C, enzymolysis time is 2 hours, pH value is maintained at 9.0, flavor protease is added at 0.3%, after enzymolysis, boil for 5 minutes to kill enzyme and sterilize; (2) Weigh 2% (w / v) vitamin B 12 powder, added in the soybean milk after enzymatic hydrolysis, and then added konjac flour, functional oligosaccharides, maltodextrin, and modified chitosan in equal proportions to prepare; (3) Utilize a cavitation jet homogenizer for processing, and the processing conditions are 25 ℃ of temperature, pressure 0.1MPa, treatment time is 25min; (4) add 0.5% modified soybean lecithin in solution, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com