Polycrystalline diamond (PCD) super-finish reamer

A diamond refining and diamond technology, which is applied in the field of PCD diamond super-precision reamer, can solve the problems of vibration, affect the roughness of the machined surface, and reduce the service life of the reamer, so as to improve the machining accuracy and prolong the service life. Longevity, the effect of avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

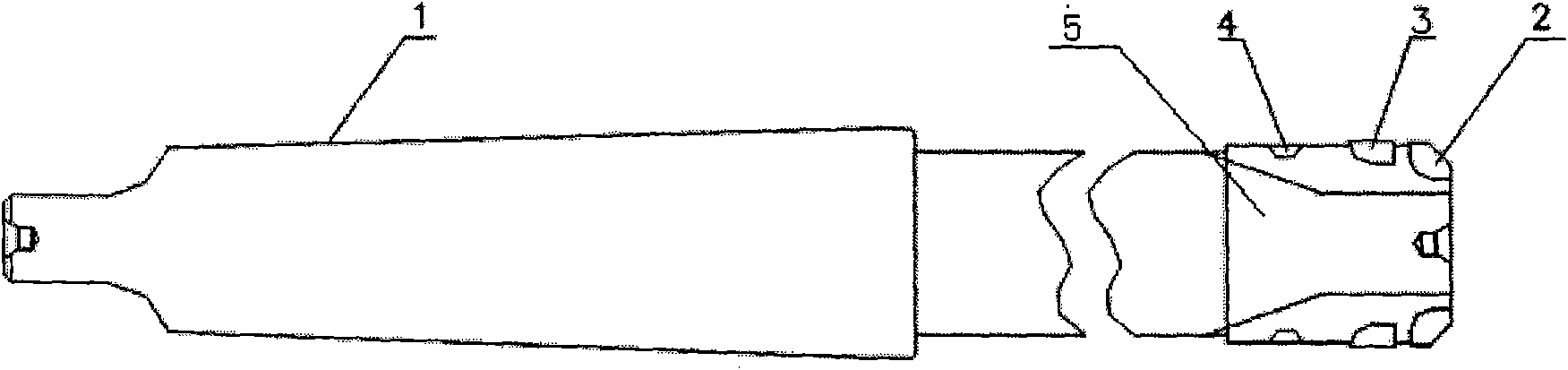

[0014] see figure 1 , a PCD diamond composite reamer 1, including a cutter body 1 and a blade 5, the front part of the blade 5 is a tungsten steel rough reamer edge 2, the middle part of the blade is a PCD diamond fine reamer edge 3, and the PCD diamond fine reamer The rear portion of the reamer blade is provided with a PCD diamond shockproof blade 4 .

[0015] In the PCD diamond composite reamer, the distance between the PCD diamond shockproof blade 4 and the PCD diamond fine reamer blade 3 is 6mm.

[0016] In the PCD diamond superfine reamer, the PCD diamond anti-vibration blade is a PCD diamond composite blade, the margin is arc-shaped, and there is no back angle.

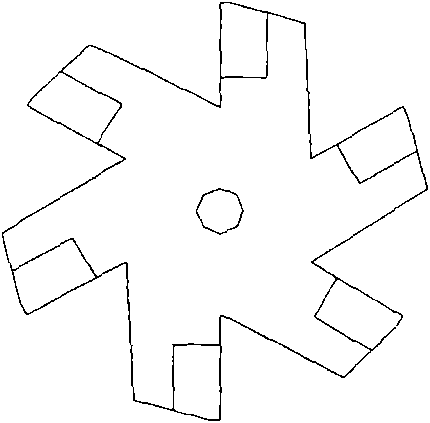

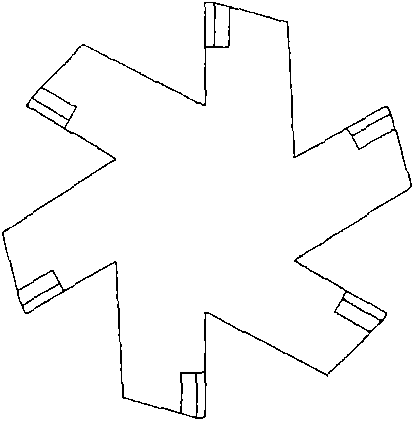

[0017] The PCD diamond superfine reamer has six PCD diamond anti-shock blades, and the three spaced blades are PCD diamond composite blades.

[0018] The present invention is not only applicable to the six-edged reamer shown in the accompanying drawings, but also includes but not limited to four-edged and eigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com