Multipurpose sleeve

A sleeve and jaw technology, which is applied in the field of bolt disassembly and assembly tools, can solve the problems of narrow application range of socket wrenches, and achieve the effect of increasing the application range and solving the narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

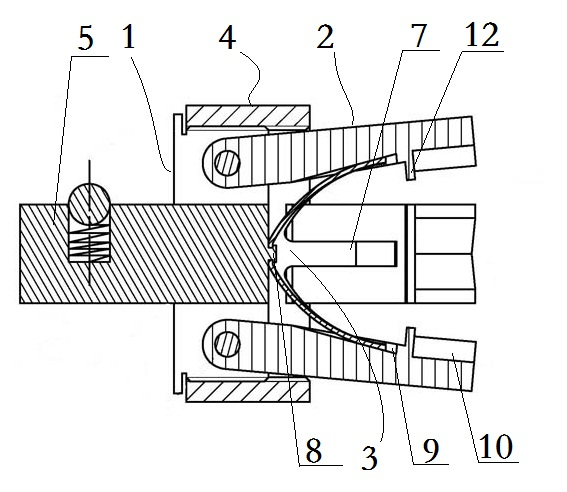

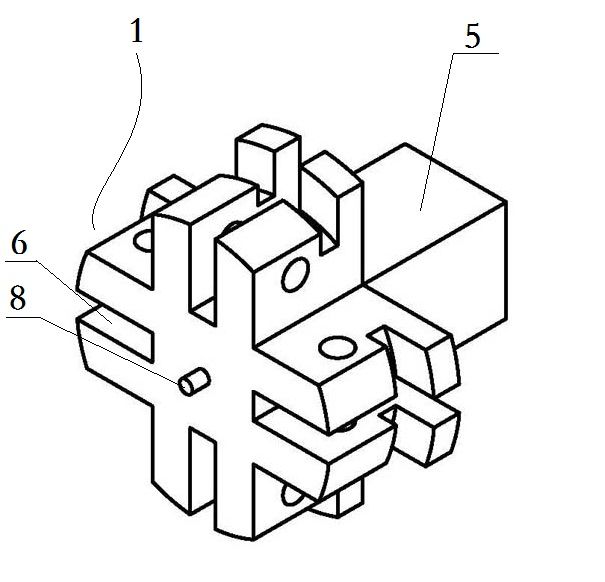

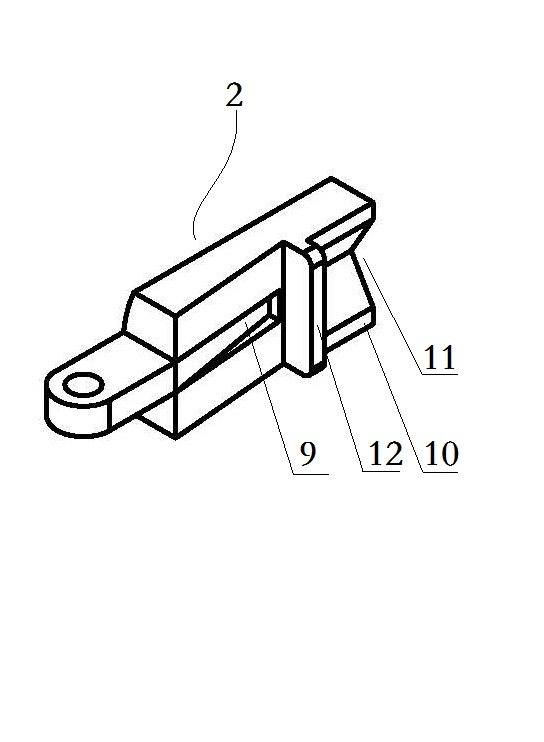

[0024] Embodiment 1 of the multipurpose sleeve of the present invention, such as Figure 1-6 As shown, it is composed of a sleeve base 1, a claw 2, an elastic skeleton 3 and an adjustment sleeve 4. One end of the sleeve base 1 has a connecting head 5 for anti-rotation assembly of the rotating handle, and the other end is evenly distributed along the circumferential direction with four hinged slots 6 for hinged jaws 2. The claws 2 are respectively hinged corresponding to the hinge groove 6 and the sleeve base 1; the elastic skeleton 3 is elastically supported between each claw 2 and the sleeve base 1, and is used to automatically keep each claw 2 in the maximum open state; the elastic skeleton 3 is formed by Four reset shrapnels 7 are composed, one end of each reset shrapnel 7 is fixedly connected together, and the other end is distributed in a divergent shape, and one end of each reset shrapnel 7 is fixedly connected to each other. After 8, it is riveted and fixed on the slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com