Combined screw hoist

A screw type, hoist technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of short effective working time, limited opening height, easy bending of the lead screw, etc., to save the total investment of the project, Great economic significance, the effect of raising the height of the door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

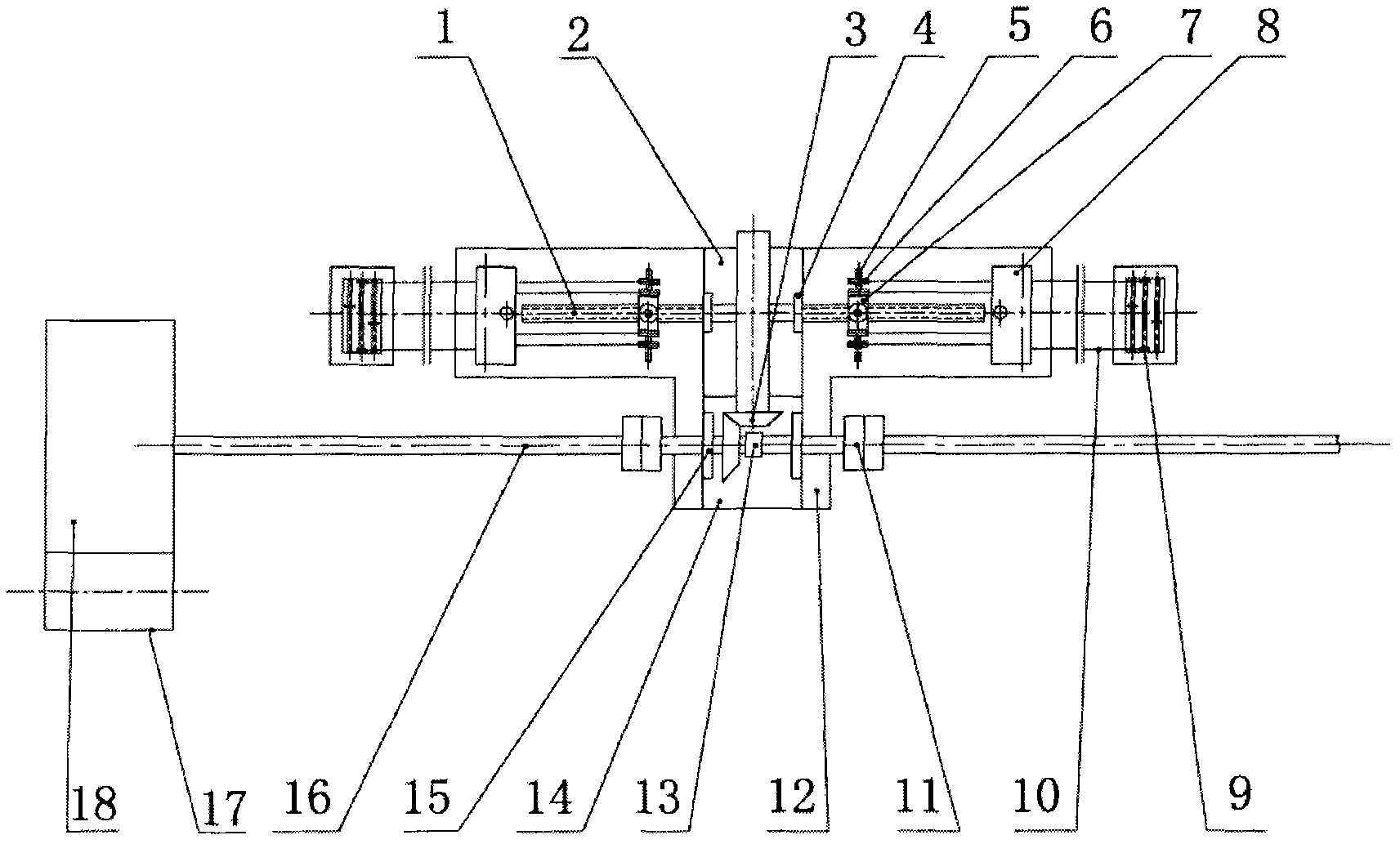

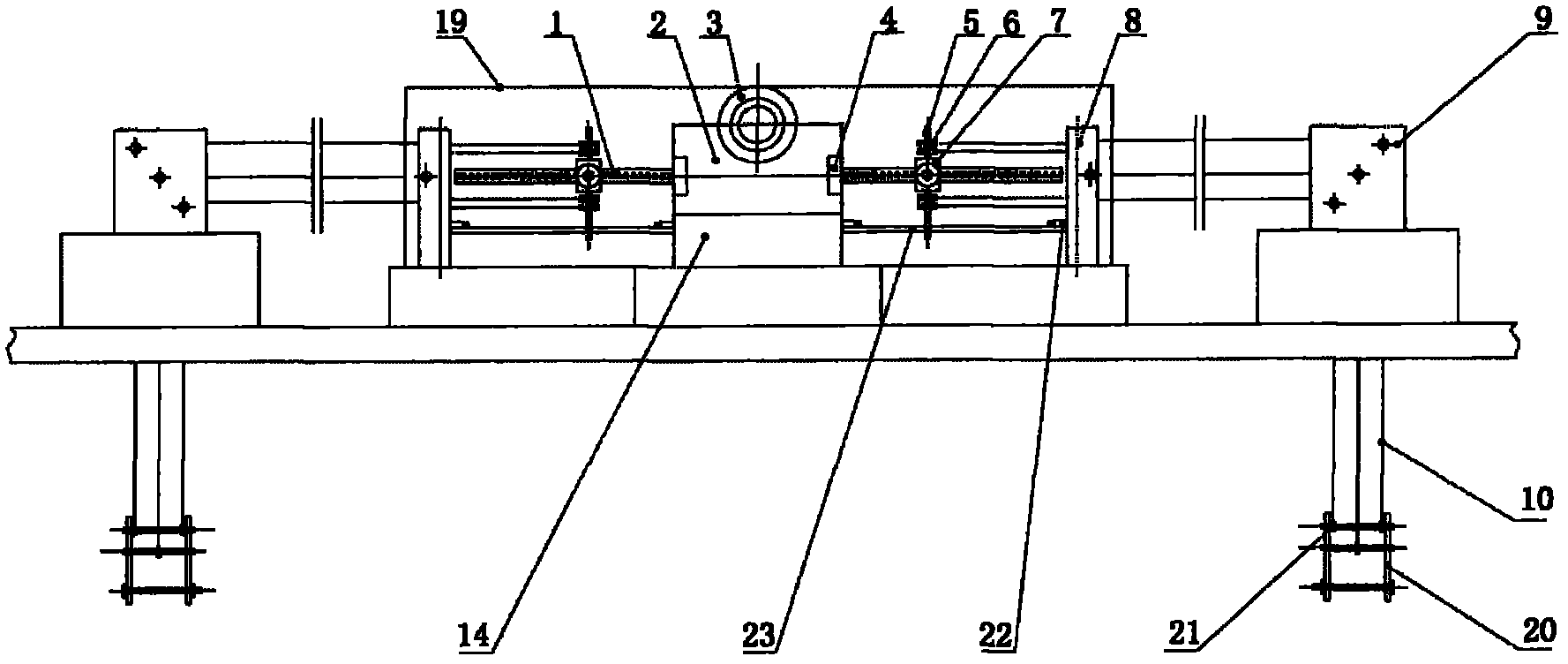

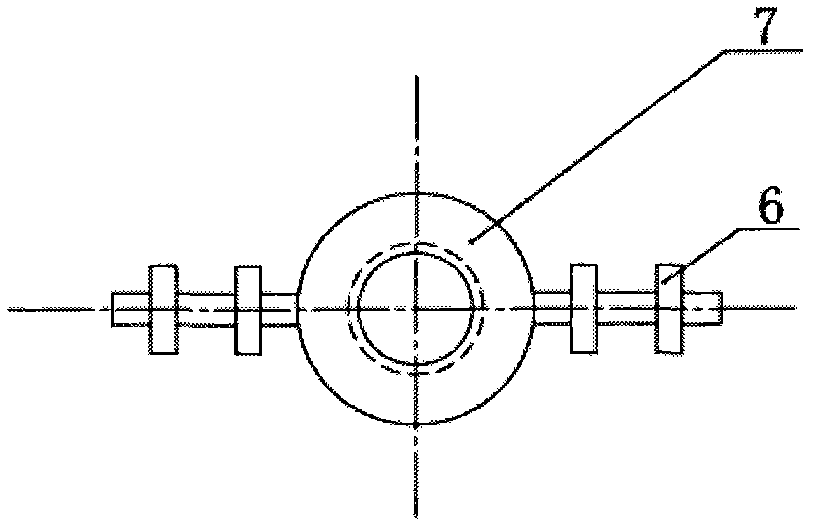

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. The combined screw hoist is mainly composed of a power machine, a transmission transmission system, a screw, a nut, a machine base and a hand crank. The screw is driven to rotate by the transmission part. On the machine base 14, a number of lead screws are arranged horizontally along the coaxial line in the direction of the gate. The part is light rod, and nuts 7 are provided on the two threads, each of which is provided with a mechanical device, which is connected with the gate through the matching mechanical facilities and connectors, and is parallel to it on one side of the connecting screw 1. A power transmission shaft 16 is set, and its end is fixedly connected with the main transmission system connected to the power machine. A transmission shifting part is set at the feed rod part in the middle of the connected lead screw 1, and a transmission part is also set at the corresponding posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com