Impact-resistant screw drill tool

A screw drilling tool and anti-impact technology, which is applied in the direction of drilling tools, drill pipes, drill pipes, etc., can solve the problems of large impact damage of universal joints, affecting service life, reducing normal service life, etc., to eliminate drill jumping and impact Vibration, improve the overall service life, increase the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

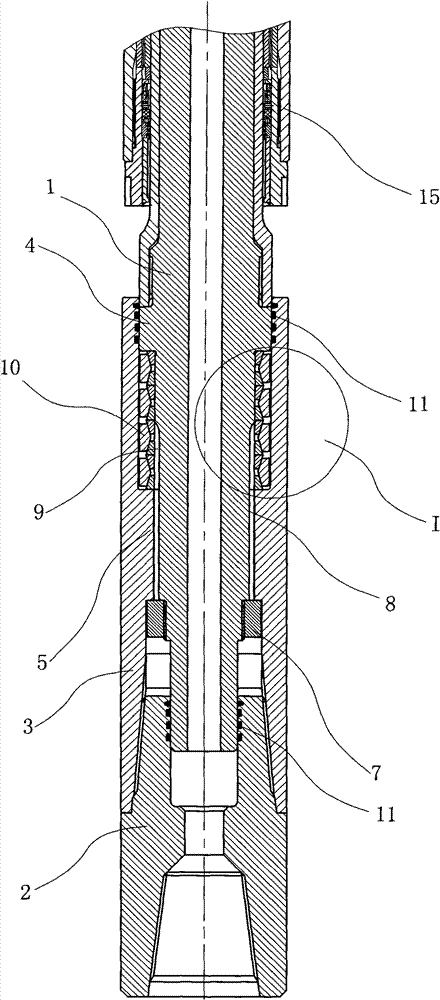

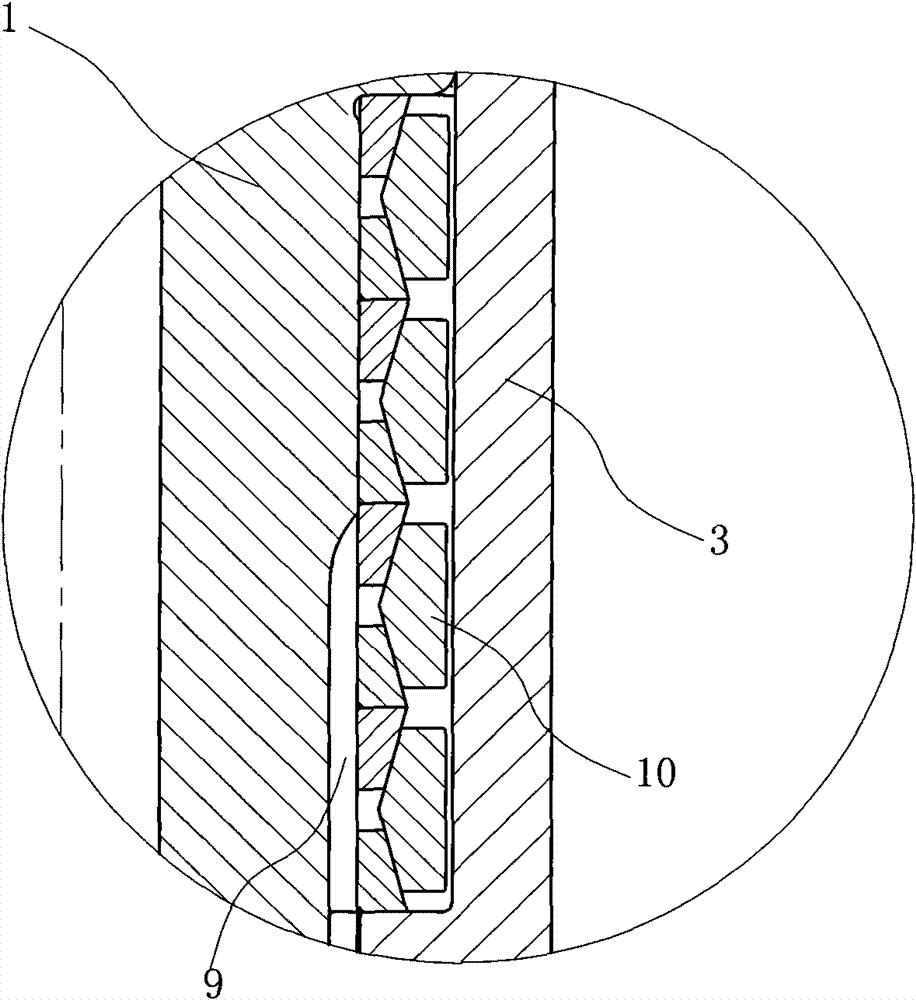

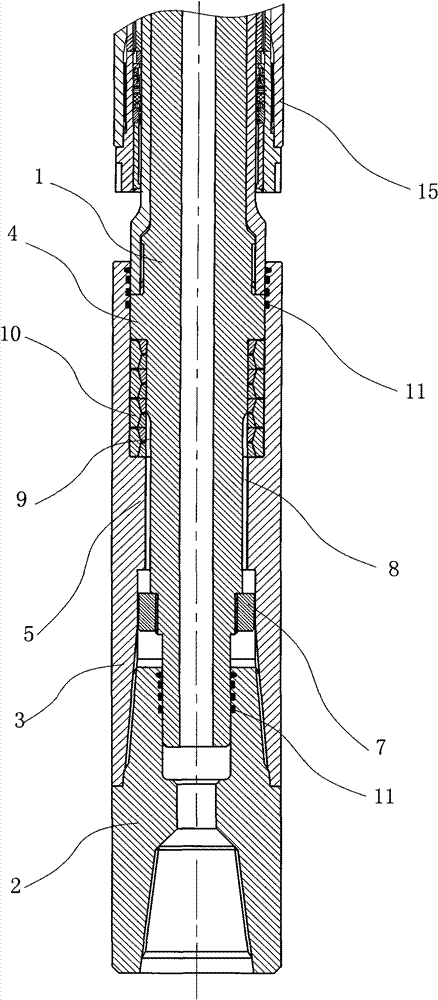

[0019] like figure 1 and figure 2 As shown, the impact-resistant screw drilling tool includes a screw drill housing 15, and a transmission shaft 1 is rotatably installed in the screw drill housing 15, and the lower end of the transmission shaft 1 protrudes from the screw drill housing 15. The lower end of the transmission shaft 1 is covered with a buffer sleeve 3 for installing a drill bit. The transmission shaft 1 and the buffer sleeve 3 are splined, and the middle part of the buffer sleeve 3 is provided with an internal spline 8. The transmission The shaft 1 is provided with an external spline 9 corresponding to the internal spline 8, and the transmission shaft 1 is provided with a buffer limit device that limits the axial movement range of the buffer sleeve 3; the transmission shaft 1 and the An axial elastic buffer device is provided between the buffer sleeves 3, and a sealing device is provided at the matching gap between the transmission shaft 1 and the buffer sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com