Method for measuring concentration of octadecylamine

A technology of concentration measurement and measurement method, which is applied in the field of chemical analysis, can solve the problems of extraction agent toxicity, error of experimental results, hazards, etc., achieve significant economic and environmental benefits, reduce operation steps, and shorten detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

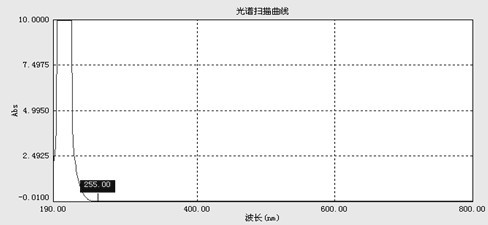

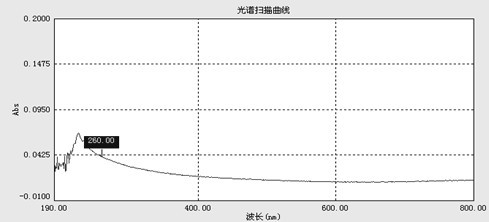

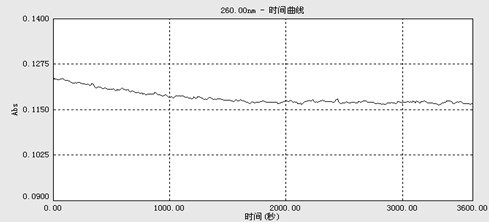

Image

Examples

Embodiment 1

[0032] Get a small amount of octadecylamine, add and dissolve completely in 100ml water containing 1ml glacial acetic acid, take desalinated water as reference, measure the absorbance at 260nm place of the solution to be 0.014, obtain the concentration of octadecylamine after querying the standard curve to be 8.46mg / L; Add 1.50 mg of octadecylamine to the solution, the absorbance measured after dissolution is 0.174, and the corresponding concentration of octadecylamine is 22.80 mg / L, calculated by the recovery formula, the recovery rate is 95.60%.

[0033] The formula for calculating the recovery rate is as follows:

[0034] R = m 2 - m 1 Δm - - - ( 2 )

[0035] Among them, m 2 Indicates the measured value after standard addition; m 1 Indicates the o...

Embodiment 2

[0037]Get a small amount of octadecylamine, add and dissolve completely in 100ml water containing 1ml glacial acetic acid, take desalinated water as reference, measure the absorbance at 260nm place of the solution to be 0.042, obtain the concentration of octadecylamine after querying the standard curve to be 10.97mg / L; Add 1.50 mg of octadecylamine to the solution, the absorbance measured after dissolution is 0.198, and the corresponding concentration of octadecylamine is 24.95 mg / L, calculated by the recovery formula, the recovery rate is 93.20%.

Embodiment 3

[0039] Get a small amount of octadecylamine, add and dissolve completely in 100ml water containing 1ml glacial acetic acid, and use desalinated water as a reference, measure the absorbance at 260nm of the solution to be 0.078, and obtain the concentration of octadecylamine after querying the standard curve to be 14.19mg / L; Add 1.50mg octadecylamine to the solution, the absorbance measured after dissolving is 0.229, and the corresponding octadecylamine concentration is 27.72mg / L, which is calculated by the recovery formula, and the recovery rate is 90.20%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap