Automatic ultrasonic detection system of circular soldering seam flaw of hydraulic bracket cylinder in mine

A coal mine hydraulic and automatic detection technology, applied in the signal transmission system, electrical signal transmission system, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the difficult quality control, quantitative and qualitative difficulties of hydraulic cylinder butt girth welds, Problems such as poor repeatability and reliability, to overcome low detection efficiency and detection accuracy, reduce dependence on professional technical level, and improve reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

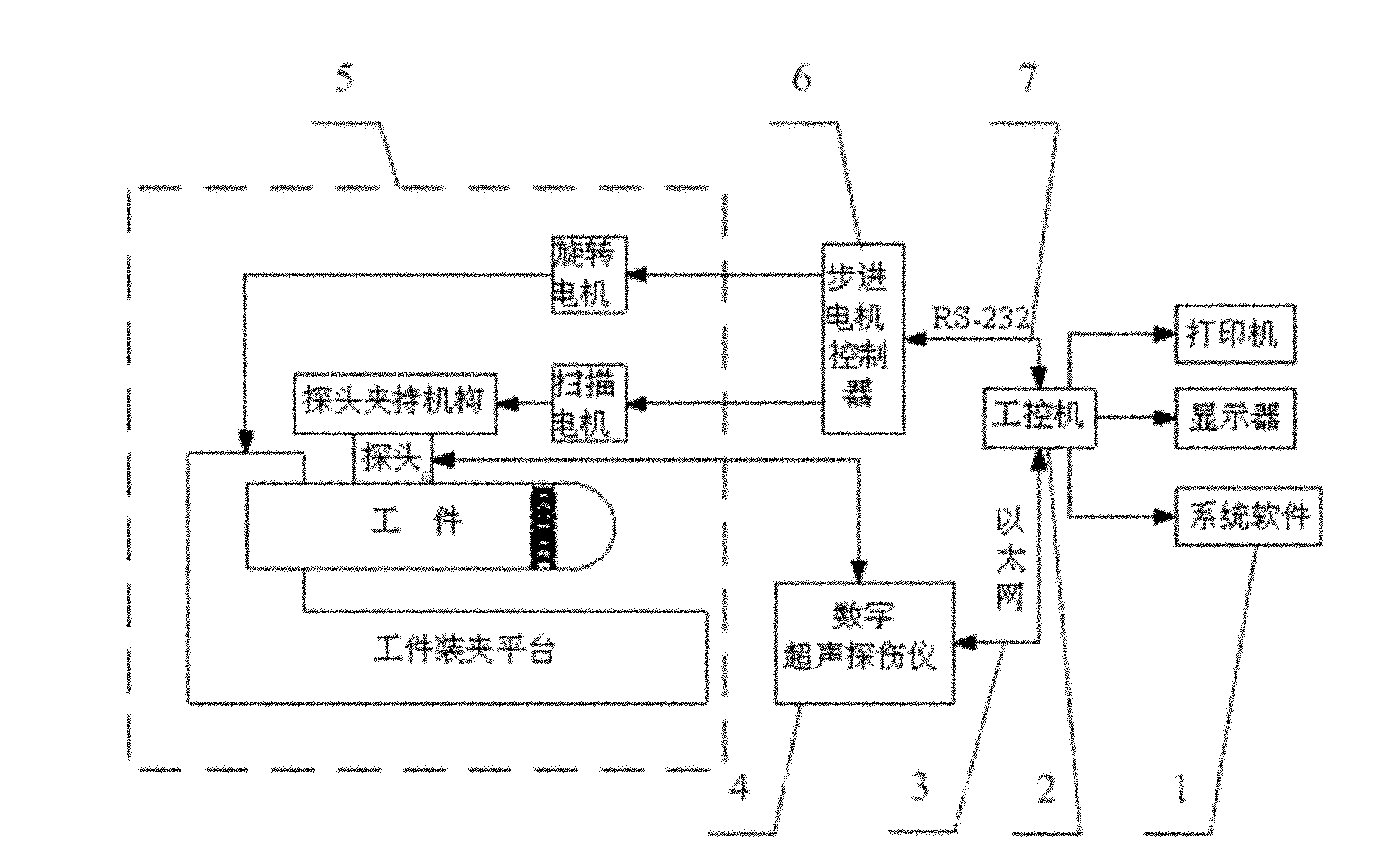

[0024] see figure 1 and figure 2 , the ultrasonic automatic detection system for coal mine hydraulic support cylinder girth weld defect of the present invention includes system software 1, industrial control computer 2, Ethernet line 3, A-type digital ultrasonic flaw detector 4, automatic scanning mechanical device 5, stepping motor controller 6 and RS-232 serial line 7, where,

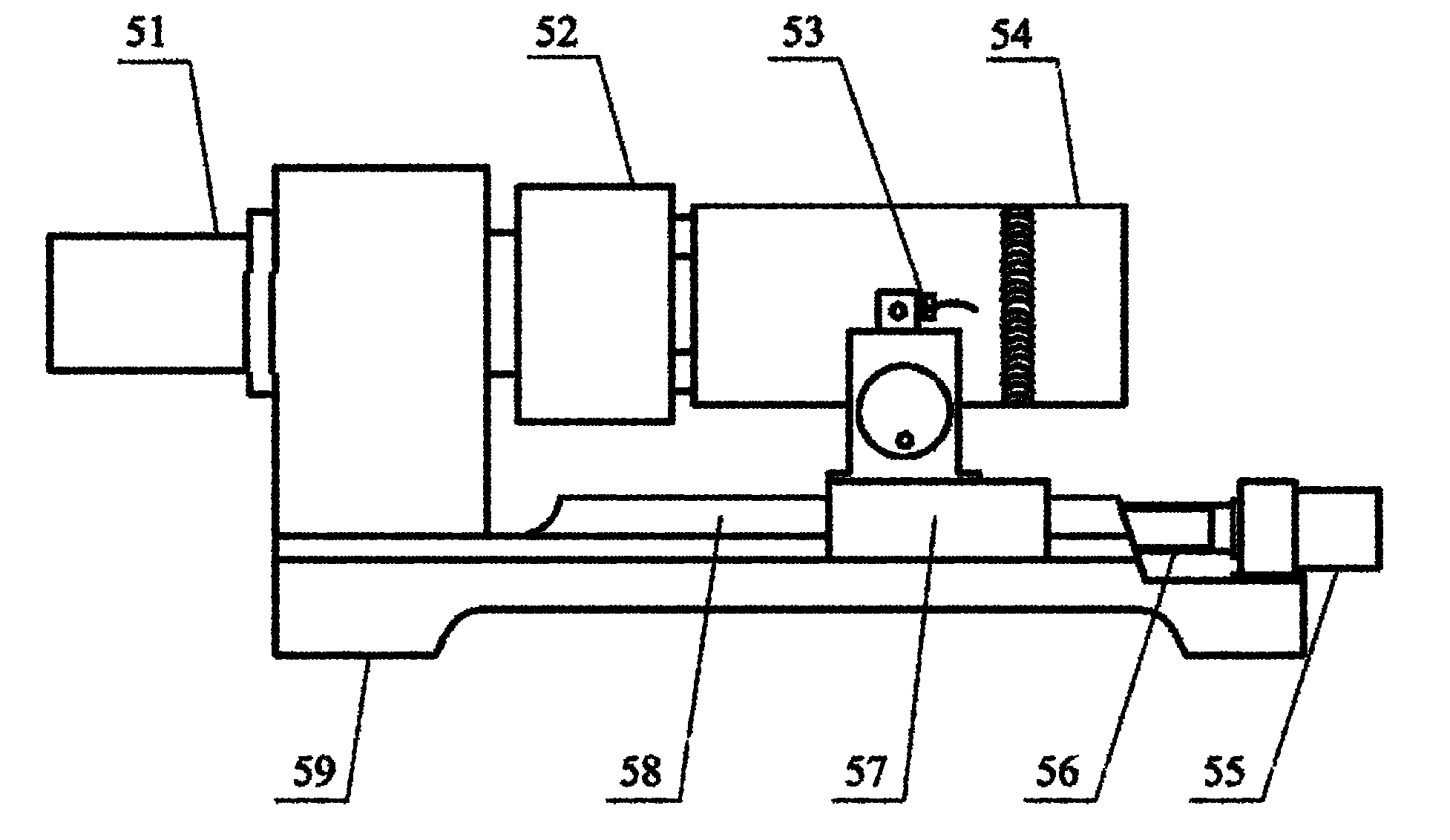

[0025] The automatic scanning mechanical device 5 includes a workpiece clamping platform 59, a rotating stepping motor 51 and a scanning stepping motor 55. The scanning stepping motor 55 drives the lead screw to rotate and drive the probe clamping mechanism 57 to move. The spindle drives the workpiece 54 in rotation.

[0026] The workpiece clamping platform 59 mainly includes a three-jaw chuck 52, a probe clamping mechanism 57, a screw nut mechanism 56 and a base, the ultrasonic probe 53 is installed in the probe clamp, and a compression spring is housed in the probe clamp to ensure that the probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com