Battery

A battery and battery soft pack technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of accelerated corrosion of the positive grid plate of the battery, affecting battery discharge performance, and short life of the battery at high temperature, so as to improve the depth Discharge performance, improved heat dissipation performance, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

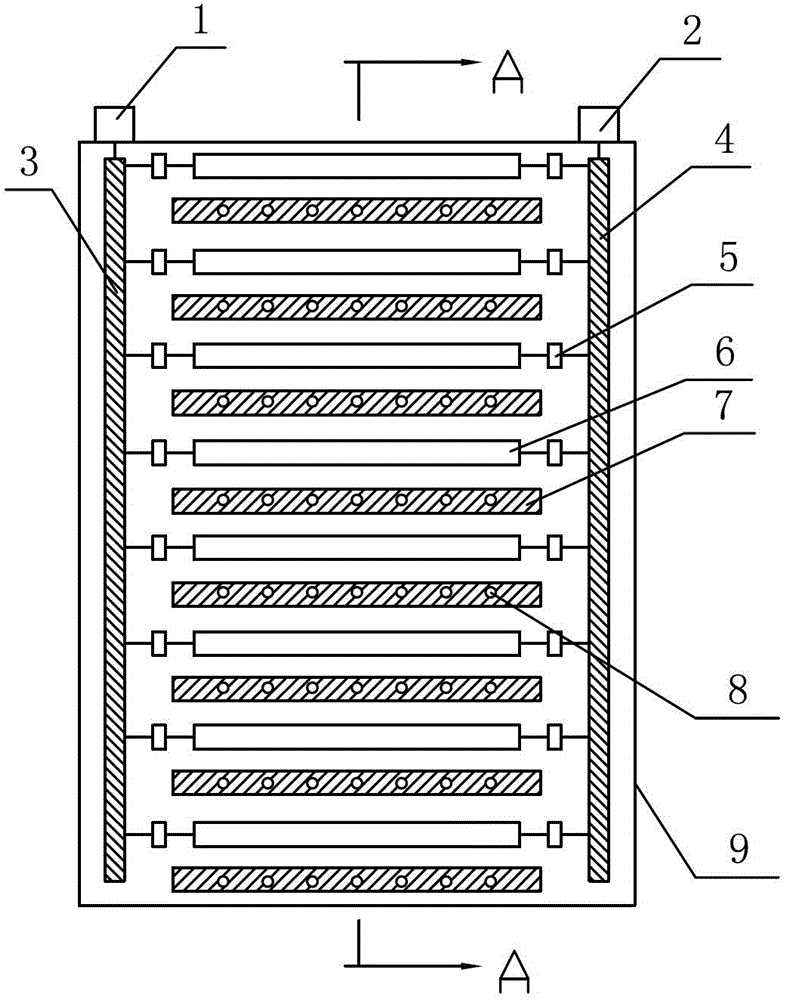

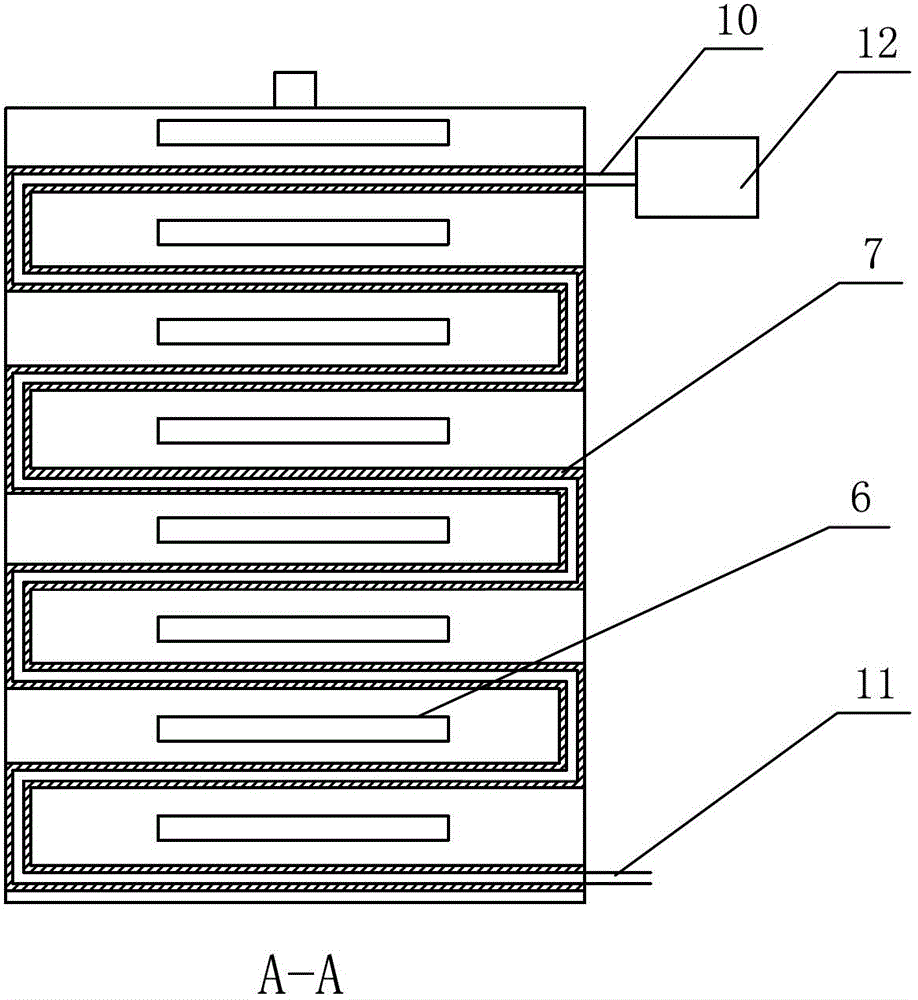

[0018] Refer to attached figure 1 :

[0019] The battery is mainly composed of positive pole 1, negative pole 2, positive bus bar 3, negative bus bar 4, fuse 5, multiple battery soft packs 6, cooling plate 7, cooling water pipe 8, battery case 9 and circulating water pump 12, The positive and negative poles 1, 2 protrude from the battery case 9, are arranged side by side on the upper part of the battery case 9, and are respectively connected to the positive and negative bus bars 2, 3 through wires. The positive and negative bus bars 3 and 4 are relatively vertically installed on both sides of the battery case 9, and a plurality of battery soft packs 6 are installed in parallel and parallel between the positive and negative bus bars 3 and 4, and the two ends are respectively connected to the positive and negative bus bars 3 and 4 through wires. Negative busbar 2 and 3 are soldered. The connecting wires are provided with fuses 5 respectively, and the fusing current of the fuse...

Embodiment 2

[0023] The positive and negative busbars 3 and 4 of the storage battery are made of silver-copper alloy, wherein the silver content is 20% and the copper content is 80%.

[0024] The battery soft pack 6 used is a colloidal maintenance-free lead-acid battery. It is composed of positive grid, negative grid, electrolyte and outer soft bag. The positive and negative electrode grids are respectively coated with lead paste, and the solid raw materials of the positive electrode lead paste are composed of the following weight units: 100kg of lead powder with a PbO content of 76%, 200g of graphite, 120g of polyester fiber, and 300g of lithium. Sodium 60g, Potassium 20g, Silver 10g; The solid raw material of negative electrode lead paste is made up of the following weight units: lead powder 100kg, polyester fiber 60g, humic acid 300g, barium sulfate 600g, acetylene black 200g, stearic acid 150g . The electrolyte is dilute sulfuric acid with a density of 1.15-1.25g / ml, and 5% lithium e...

Embodiment 3

[0026] The solid raw material of the positive lead paste of the battery soft pack 6 of this accumulator is made up of the material of following weight unit: the content of PbO is 80% lead powder 100kg, graphite 250g, polyester fiber 100g, lithium 250g, sodium 50g, potassium 25g , silver 5g; The solid raw material of negative pole lead paste is made up of the material of following weight unit: lead powder 100kg, polyester fiber 70g, humic acid 250g, barium sulfate 650g, acetylene black 150g, stearic acid 100g. The electrolyte is dilute sulfuric acid with a density of 1.15-1.25g / ml, and 5% lithium element is added to it. The grid alloy is a Pb-Ca-Ag alloy, in which the Ca content is 5%, the Ag content is 0.1%, and the rest is Pb. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com