Transformer substation sequentialization control system with visualization and interactivity

A substation and control system technology, applied in information technology support systems, electrical components, circuit devices, etc., can solve the problems of low intelligence, single function, lack of interaction, etc., and achieve the effect of enhancing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] This part reveals the content of the present invention in the following order:

[0037] (1) Embodiments of the present invention;

[0038] (2) Example 1 of the above-mentioned embodiment;

[0039] (3) Example 2 of the above embodiment.

Embodiment approach

[0041] The invention discloses a substation sequential control system with visualization and interactivity, which standardizes and models the operation content of the sequence control operation ticket, so that the sequence control can be standardized and unified. The control system includes:

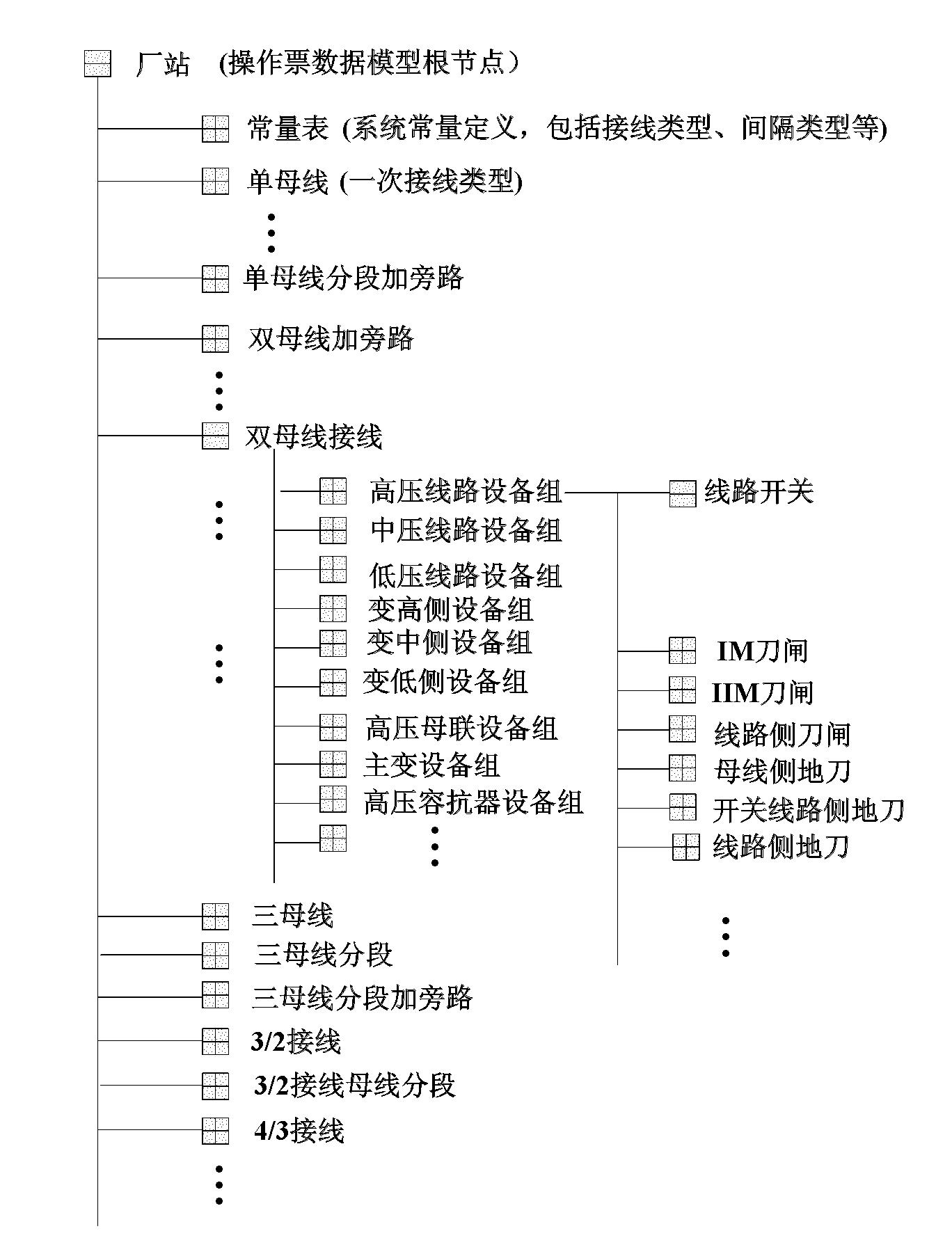

[0042] The intelligent generation sequence control operation ticket module is used to generate a sequence control template operation ticket that has nothing to do with the specific substation equipment, and can map the content of the template operation ticket to the actual interval and equipment in the specific substation to generate a sequence control specific operation ticket;

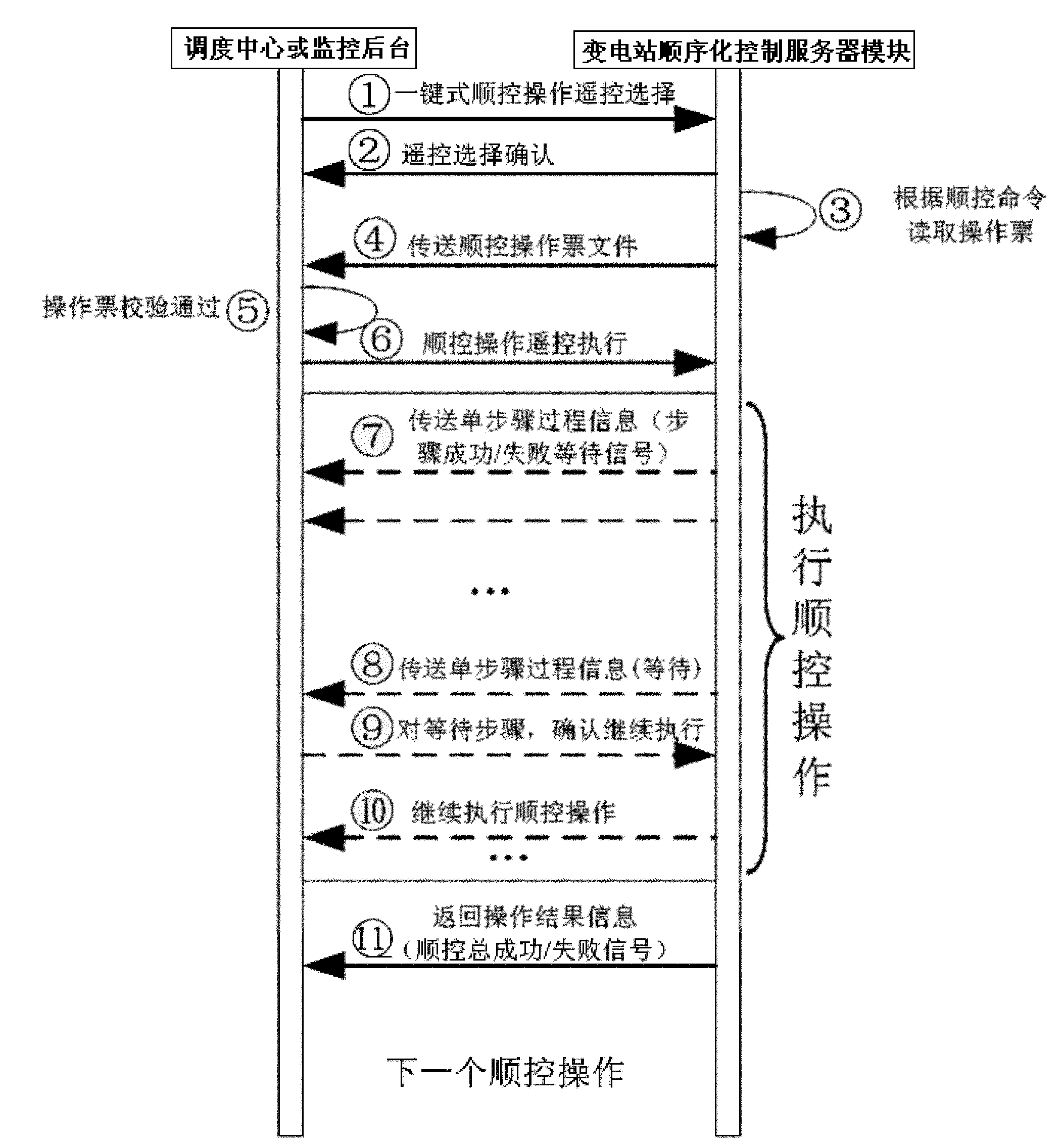

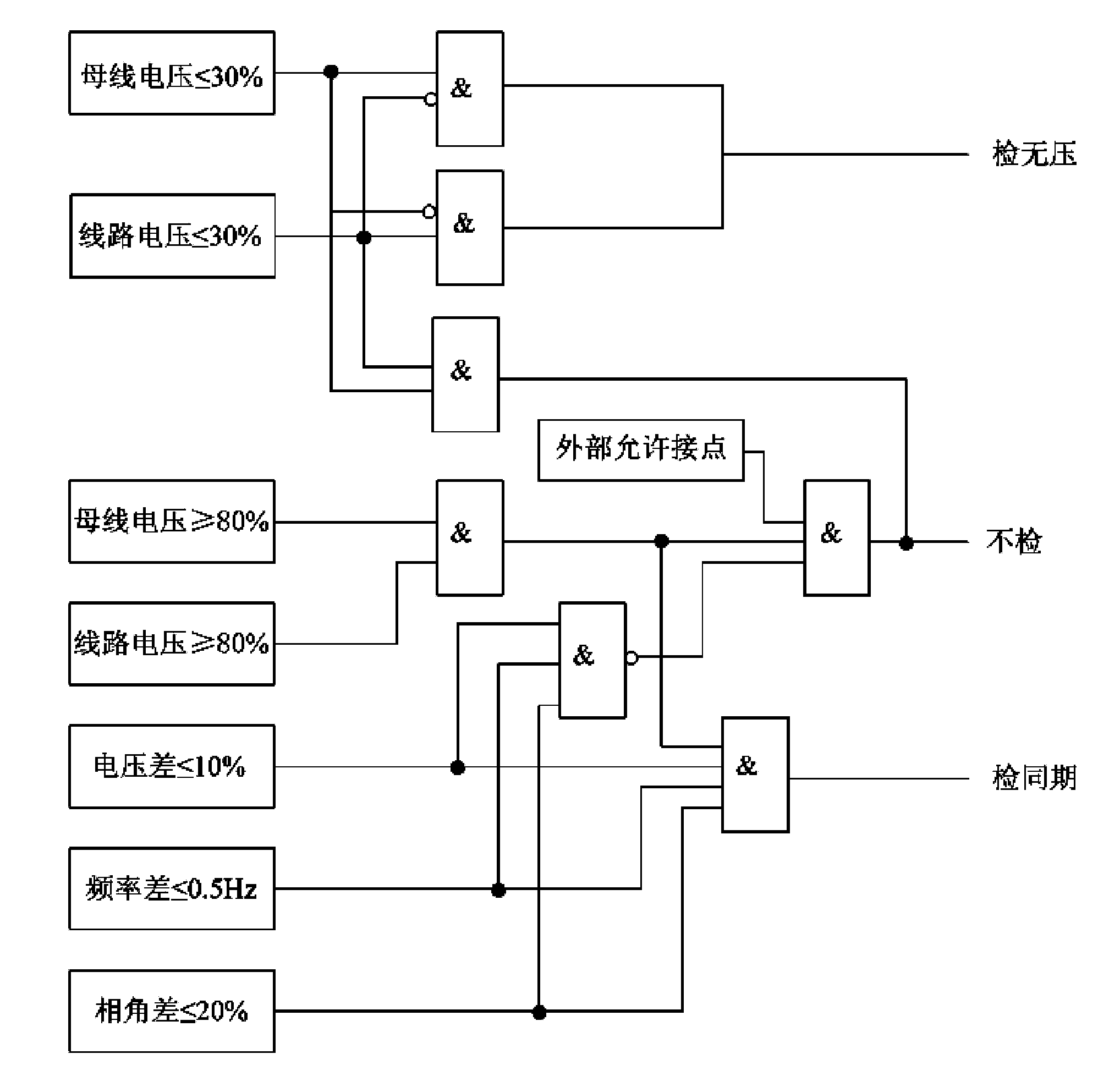

[0043]The sequence control server module is used to read the sequence control specific operation ticket generated by the intelligent generation sequence control operation ticket module and perform actual control on the specific substation equipment through the standard control device according to the content of t...

Embodiment 1

[0071] The following is an actual execution of a sequential control task: changing the incoming line switch of the double-bus connection mode incoming line equipment group from running to cold standby, and illustrating the execution process of the present invention when actually controlling a specific substation:

[0072] First, the intelligent generation sequence control operation ticket module of the present invention edits the content involved in the sequence control template operation ticket according to the defined constant type:

[0073] Sequential control task name: Change the incoming line switch of the double-bus wiring mode incoming equipment group from running to cold standby; among them, the primary wiring type constant is: double busbar wiring, and the interval type constant is: incoming line equipment group, primary equipment type constant It is: switch, the equipment subtype constant is: I female switch, II female switch, the operation type constant is: check tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com