Improvements in or relating to multi-leaf collimators

A multi-leaf collimator, blade technology, applied in the direction of using diaphragm/collimator, X-ray/γ-ray/particle irradiation therapy, radiation/particle treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

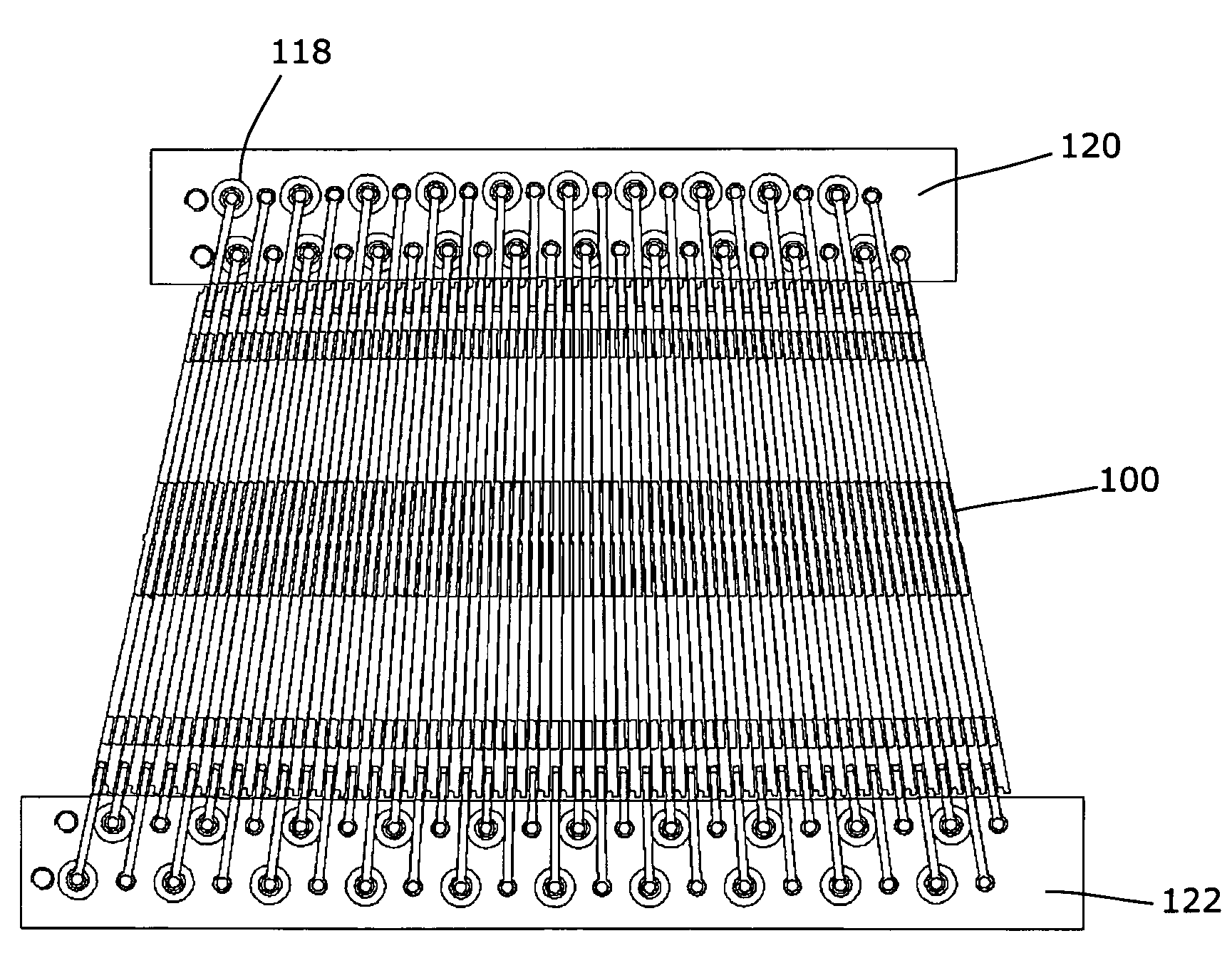

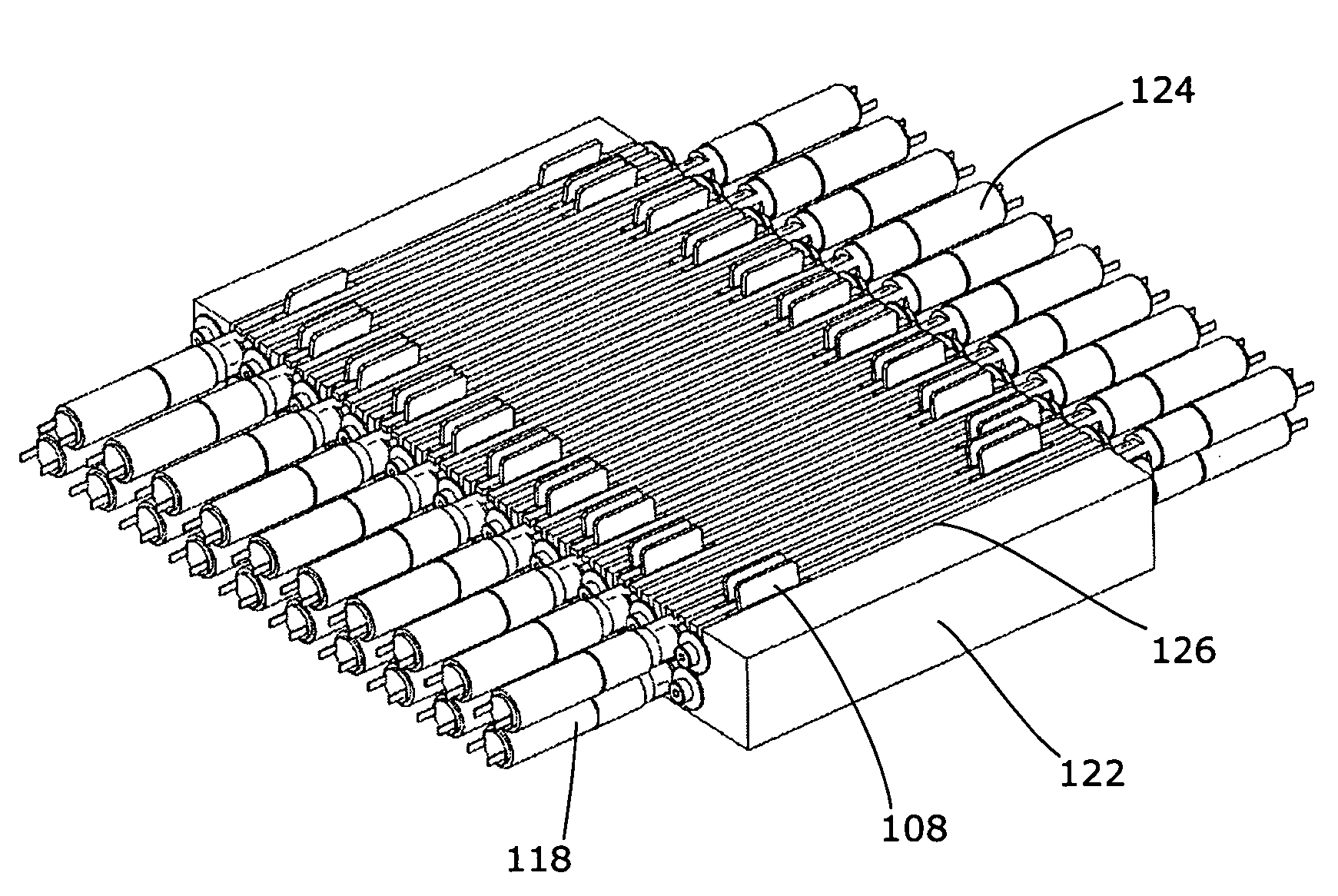

[0035] An inherent limitation on the minimum length of a rack and pinion system is the number of motors mounted on the side of the assembly. For example, assuming each assembly is designed to drive 40 blades, each motor is 10 mm in diameter and (therefore) spaced 14 mm apart in two rows, the length of the assembly must be 14×(40 / 2), That is 280 mm, plus the distance each blade is expected to travel. If we take a rough figure of 70 mm for this distance, this makes the total length of the system 350 mm. The minimum overall height is the diameter of the motor plus the height of the rack, ie approx. 32 mm. The rack and pinion assembly will thus significantly increase the treatment head diameter when mounted on the blade set.

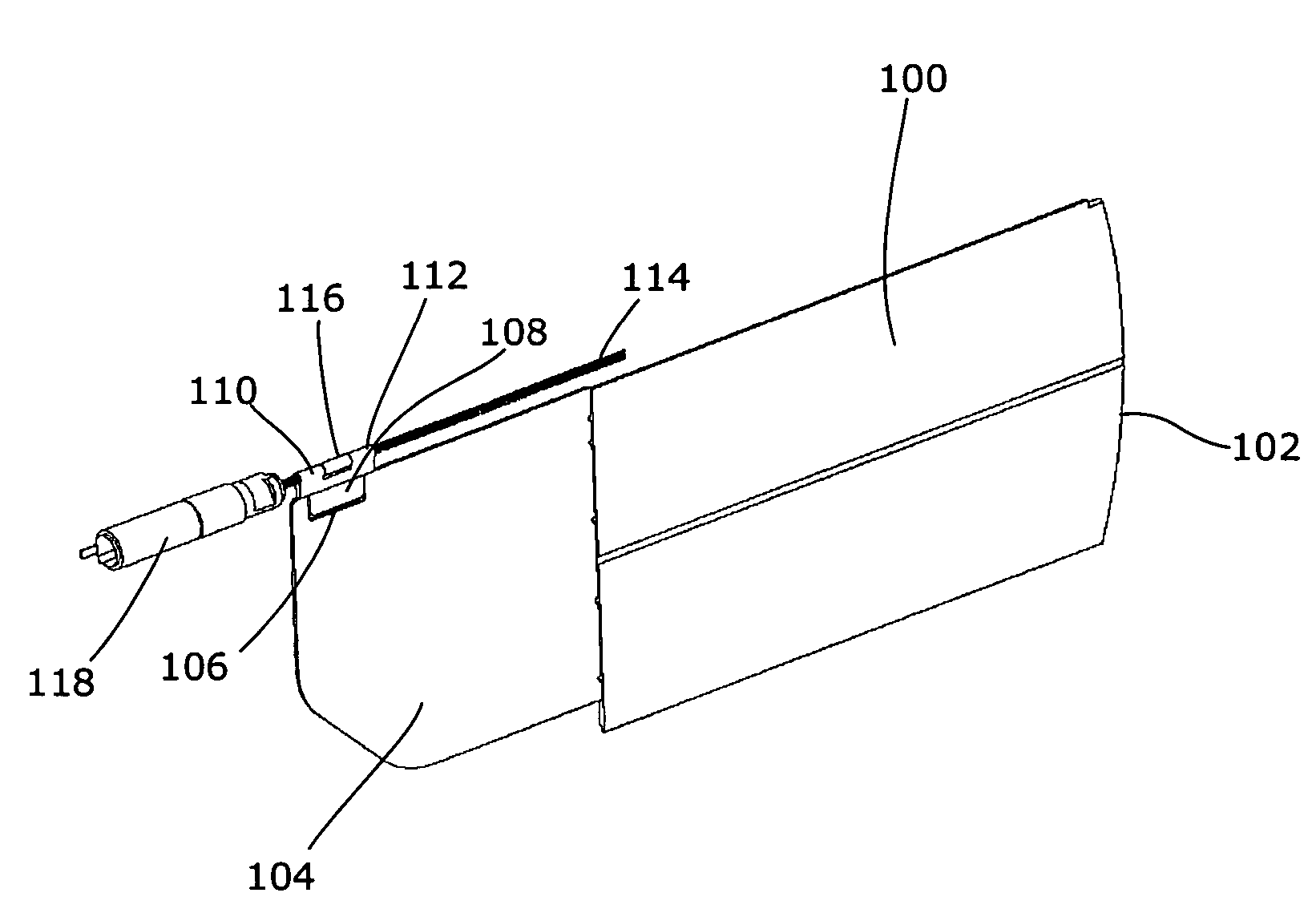

[0036] The MLC actuator described here features a lead screw that runs parallel to the blades, which means that the length of the drive assembly is overall shorter because the lead screw only needs to be slightly longer than the required blade travel. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap