Preheating device

A preheating device and cylinder technology, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of energy waste, the inability to fully utilize steam heat, and the inability to preheat the evaporation temperature of the solution, and achieve stable preheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

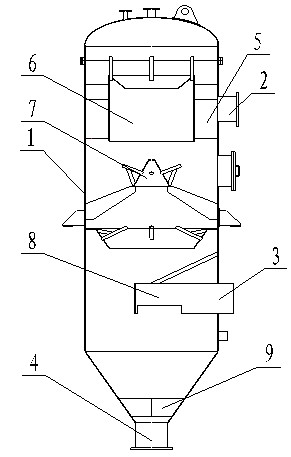

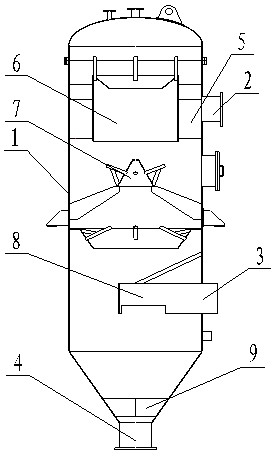

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] like figure 1 As shown, the preheating device includes a cylinder body 1, a solution inlet 2 arranged at the upper part of the cylinder body 1 and a steam inlet 3 arranged at the lower part of the cylinder body 1, a solution outlet 4 is arranged at the lower end of the cylinder body 1, and a solution outlet 4 is arranged inside the cylinder body 1 There is a transition chamber 5 connected to the solution inlet. The transition chamber 5 is provided with an inner cylinder 6 with a hollow center, and a membrane distributor 7 is arranged below the inner cylinder 6. The cylinder body 1 is also provided with one end connected to the steam inlet 3 and the other A steam pipe 8 with one end opening downward, the steam pipe 8 is located below the membrane distributor 7 . In order to prevent the solution from forming a vortex at the solution outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com