Welding pellet locatable and detachable support

A welding ball and bearing technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as deformation, slow construction speed, and no standardization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

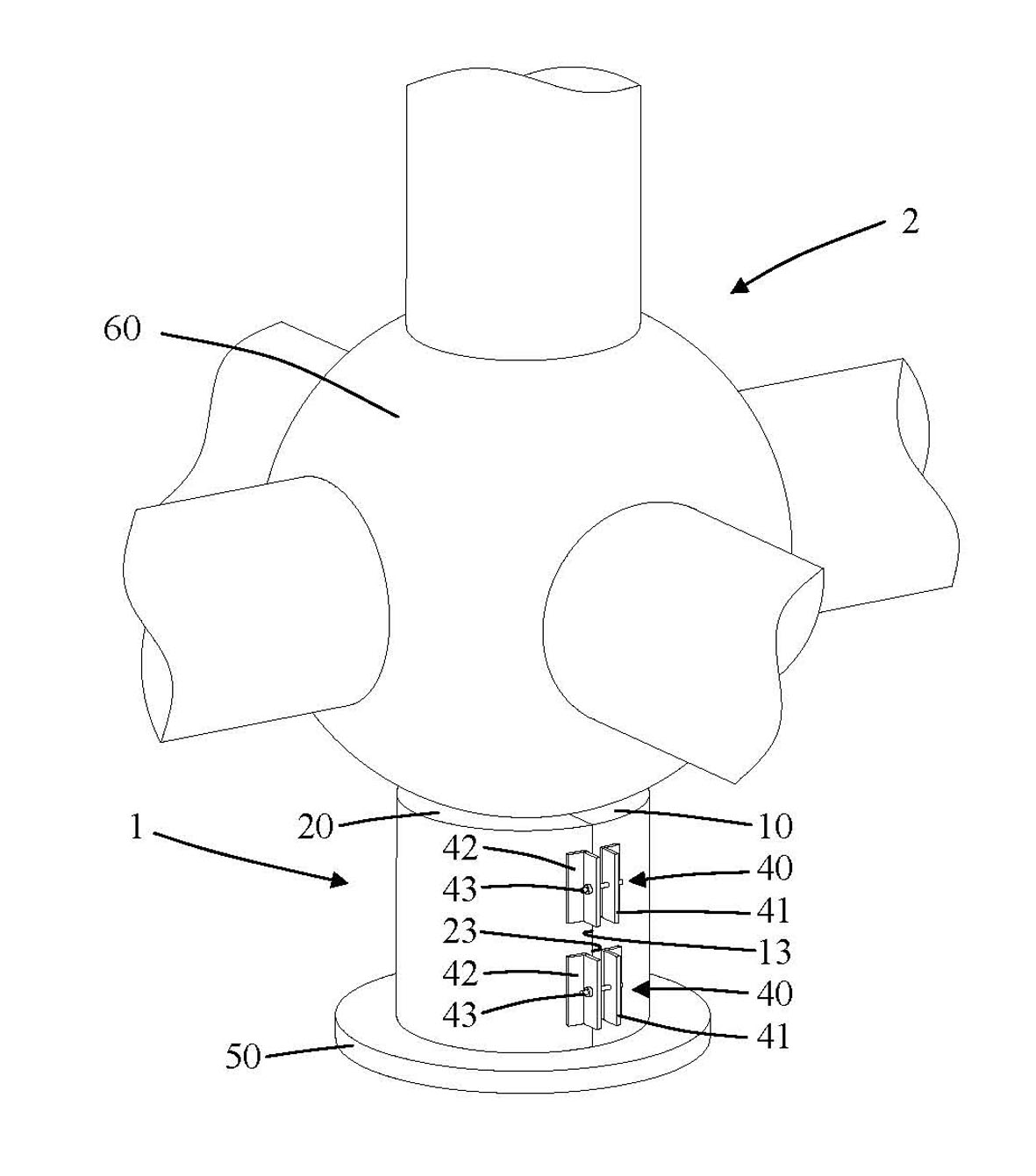

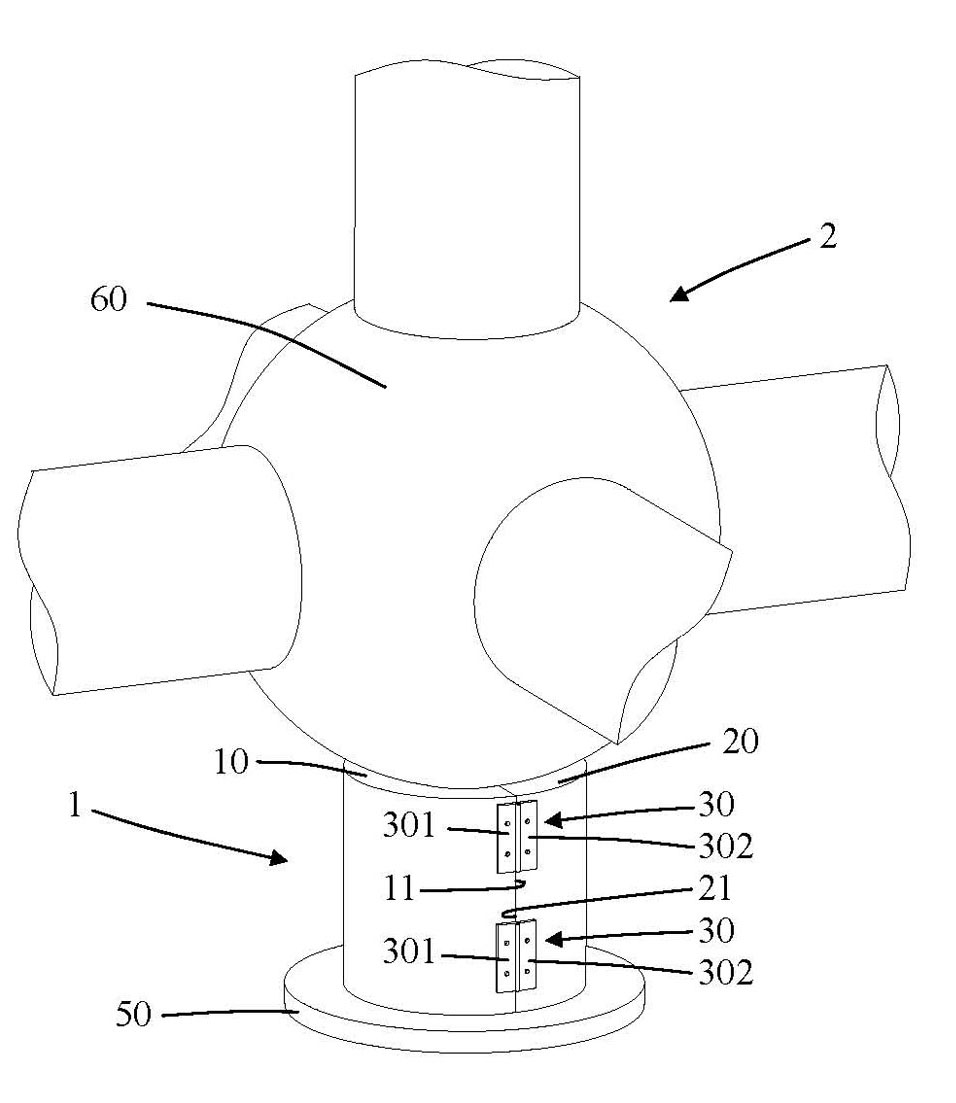

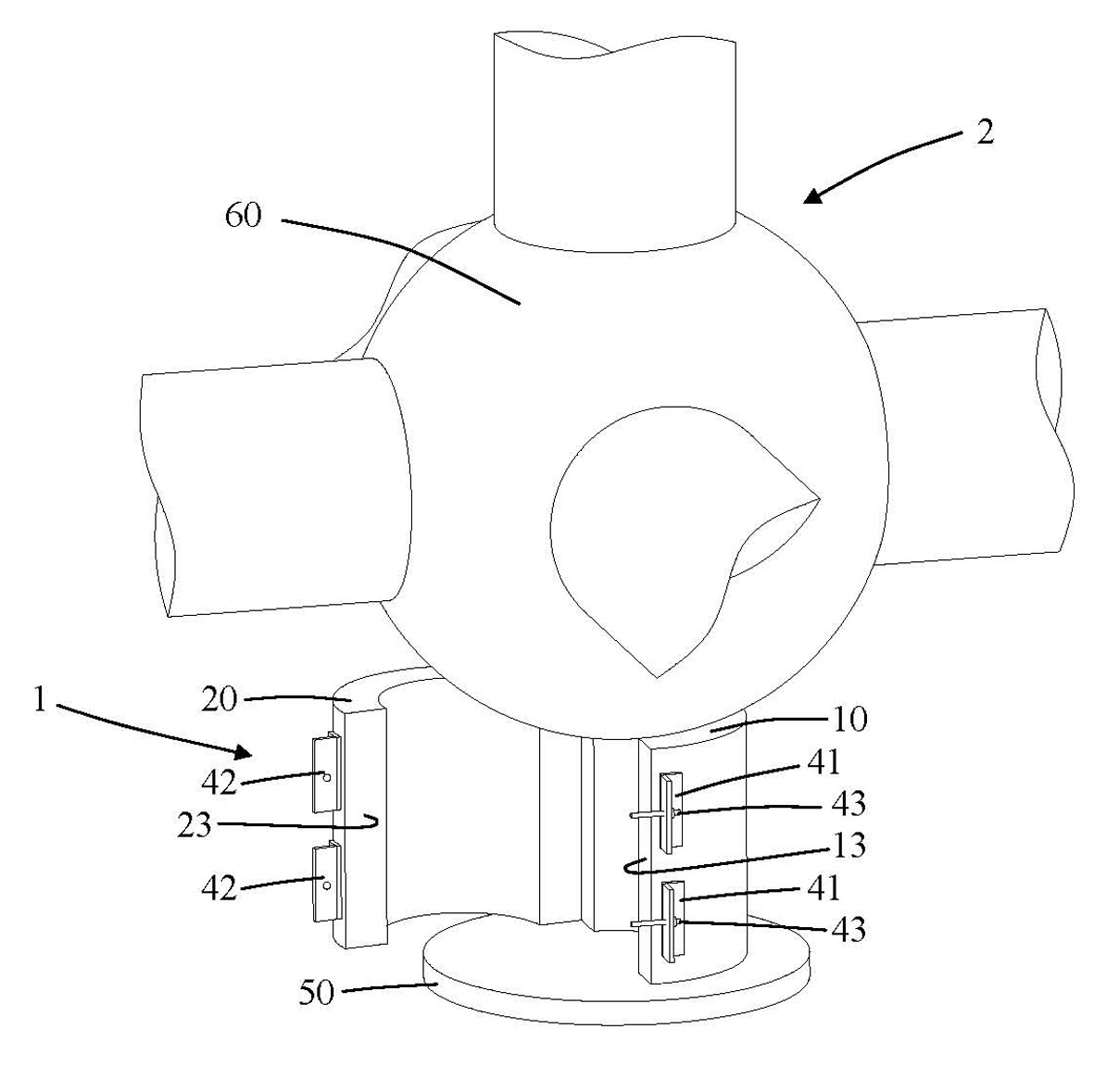

[0014] see figure 1 , figure 2 As shown, the welding ball positioning and detachable support 1 of the present invention includes a first semicircular tube 10, a second semicircular tube 20, two hinges 30, two fasteners 40 and a base 50, wherein:

[0015] The first semicircular pipe 10 and the second semicircular pipe 20 all adopt a semicircular steel pipe whose radius is less than the radius of the welding ball 60 of the welded ball grid frame 2. The first end 301 of the hinge 30 is fixed on the edge of the first side wall 11 of the first semicircular tube 10, the second end 302 of the hinge 30 is fixed on the edge of the first combined side wall 21 of the second semicircular tube 20, the second The second semi-circular tube 20 can pivot around its connection surface with the first semi-circular tube 10 through the hinge 30 . The first part 41 of the fastener 40 is affixed to the second side wall edge of the second side wall 13 of the first semicircular pipe 10, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com