Wide zero-speed material replacing and splicing system and replacing and splicing method

A zero-speed, wide-width technology, which is applied in the wide-width zero-speed splicing system and the field of splicing, can solve the problems of material fracture and difficult material tension, and achieve good rigidity, weight reduction, and reliable splicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

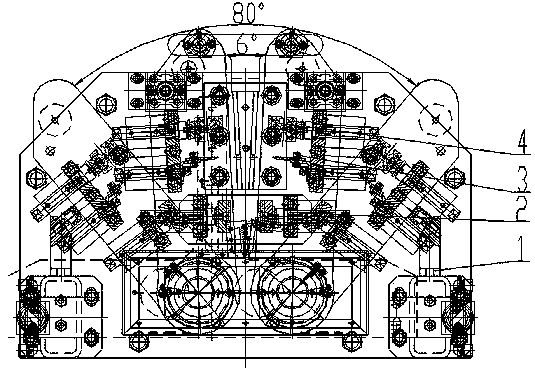

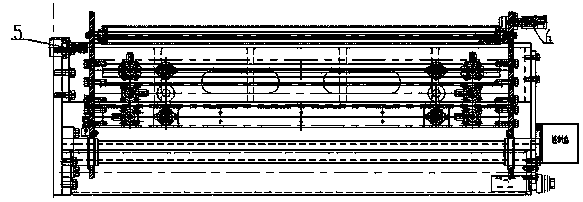

[0010] Embodiment 1: with reference to attached figure 1 and 2 . The wide-width zero-speed material change system includes a material receiving device 2, a material cutting device 3 and a material pressing device 4. It is composed of a linear bearing and a guide rod, wherein the guide rod is connected to the pressure plate through a floating joint, and the feeding device 2, the cutting device 3 and the pressing device 4 are symmetrically arranged.

[0011] The material receiving device 2 and the material cutting device 3 are respectively composed of two internal and external cylinders, two linear bearings and a guide rod, wherein the guide rod is connected with the pressure plate through a floating joint to improve the cylinder when pushing and pushing out. The actuator runs flexibly, smoothly, and the service life of the cylinder and linear bearings is guaranteed.

[0012] The material receiving device 2 and the material cutting device 3 are symmetrically arranged.

[001...

Embodiment 2

[0014] Embodiment 2: On the basis of Embodiment 1, the method of changing material of the wide-width zero-speed material changing system, (1) Opening: firstly, one hand presses the knob button, the cylinder 5 shrinks, and the inner positioning pin pops up, and the Pull open the spring positioning handle 6 and hold it tightly, hold the spring positioning handle tightly and put one side of the mechanism outside. When the mechanism runs to an angle of 40 degrees, the inner and outer rocker arms just hit the upper limit rod 1, and you can release the handle at this time , pull the material roll to change the material, after the refueling is ready; (2) Close: Hold the spring positioning handle 6 and rotate the outer rocker arm of the mechanism to the positioning hole of the spring positioning handle 6, insert it into the hole to realize the outer positioning, and at the same time , press the knob button with the other hand, and the limit cylinder 5 drives the guide pin to insert int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com