Patents

Literature

44results about How to "Neat fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

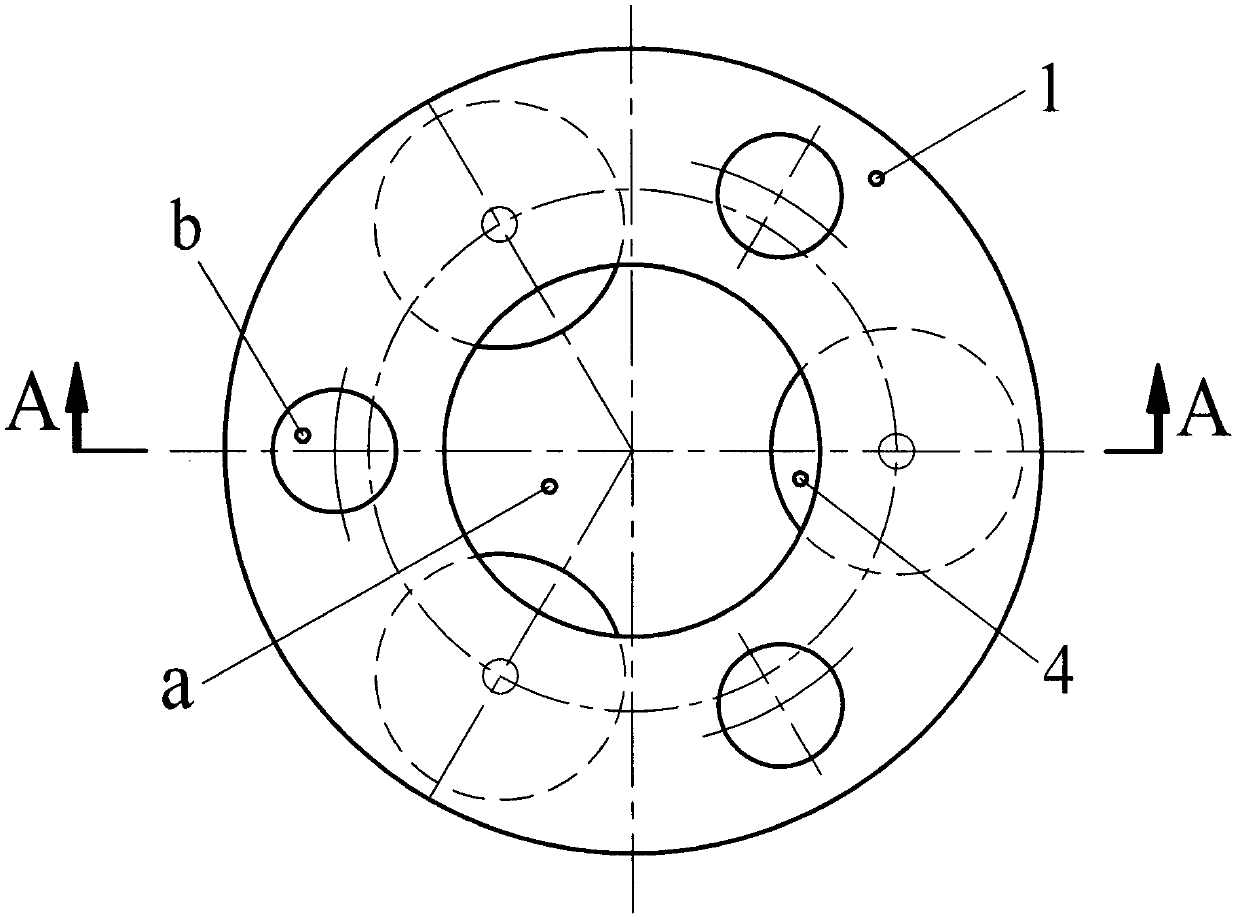

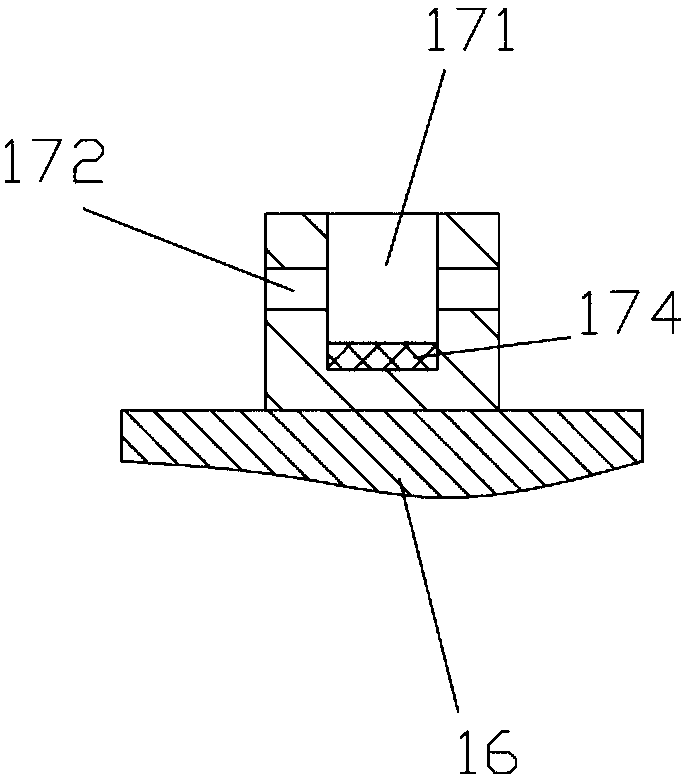

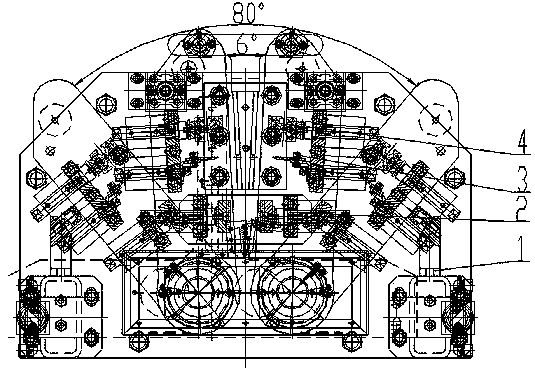

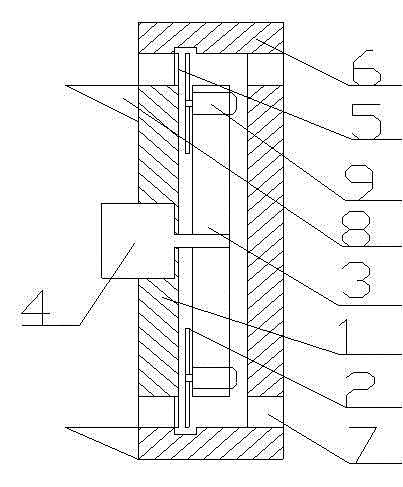

Tool for cutting and breaking ampule

ActiveCN103288023ANot easy to polluteAmpoule cutting time reducedBottle/container closurePower operated devicesEngineeringGrinding wheel

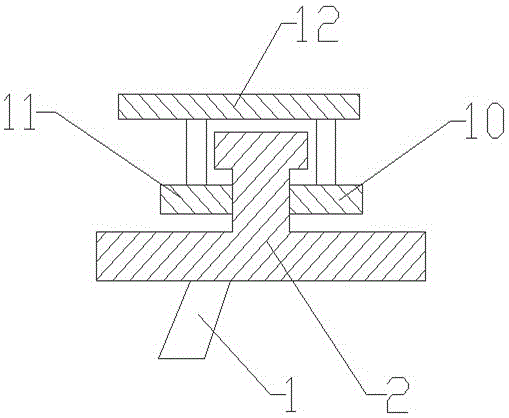

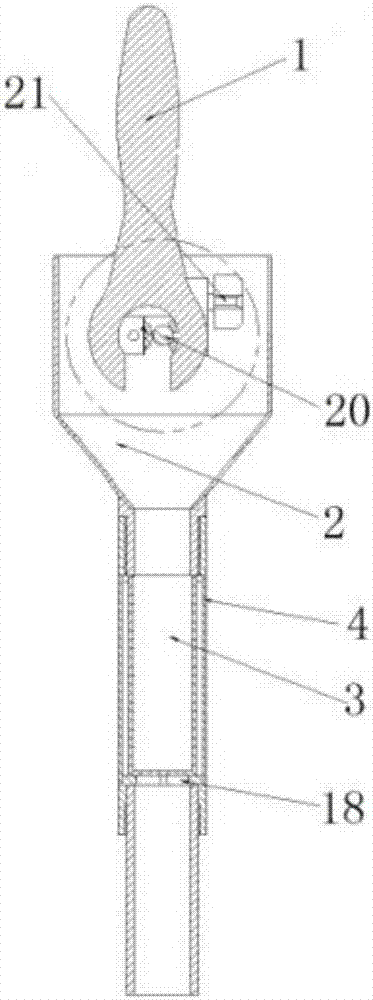

The invention relates to a tool for cutting and breaking an ampule. The tool comprises a body (1), grinding wheels (4), a screw (2), a rubber gasket (3) and a rubber cover plate (5), wherein a plurality of grinding wheels (4) with center holes are fixed in a groove of the body (1), and the inside cutting edges of the grinding wheels (4) are exposed in the position of an inner hole (a) of the body (1); the rubber gasket (3) and the rubber cover plate (5) are propped against upper planes and lower planes of the grinding wheels (4) respectively; one circular truncated cone-shaped breaking hole (b) used for breaking the ampule is formed between every two grinding wheels; the body (1) can be held by a hand and rotates by one third of a circumference, and then full circular arc cutting of the ampule at angle of 360 degrees is realized; and the ampule breaking holes are used for breaking the ampule, so that the ampule can be broken easily, and the condition that fingers of a nurse are scratched by broken glass pieces when the nurse breaks the ampule with hands is avoided. Two actions of scratching and breaking of the ampule can be continuously finished, the operation is simple, the use is safe, time and labor are saved, and the labor intensity of the nurse is reduced.

Owner:盐城市瑞华机电制造有限公司

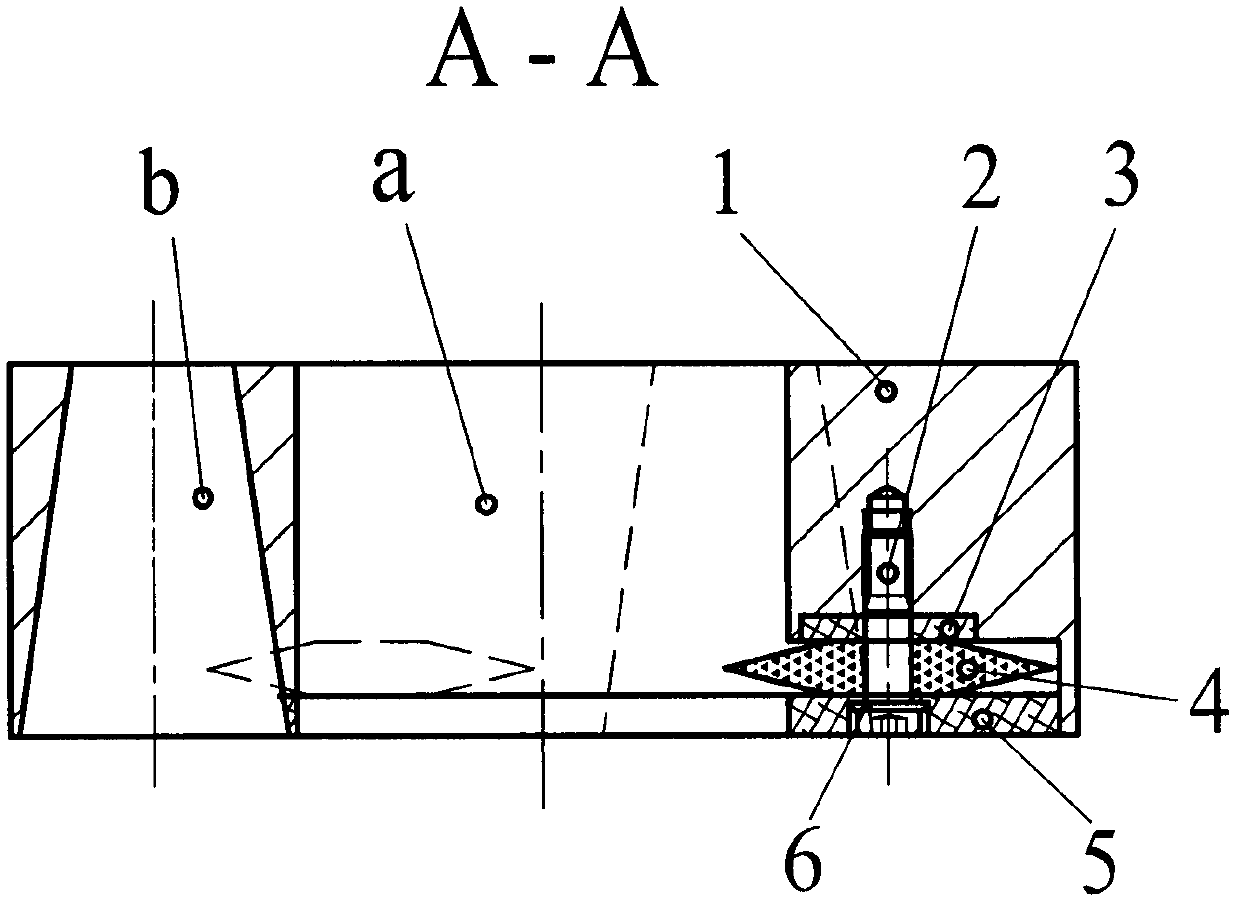

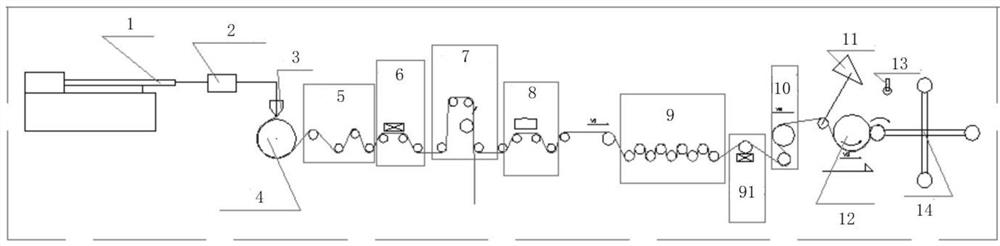

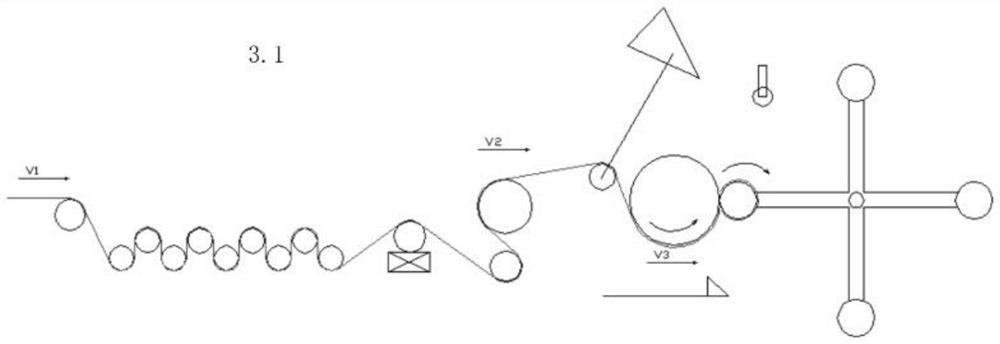

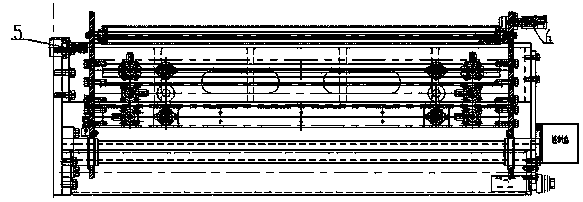

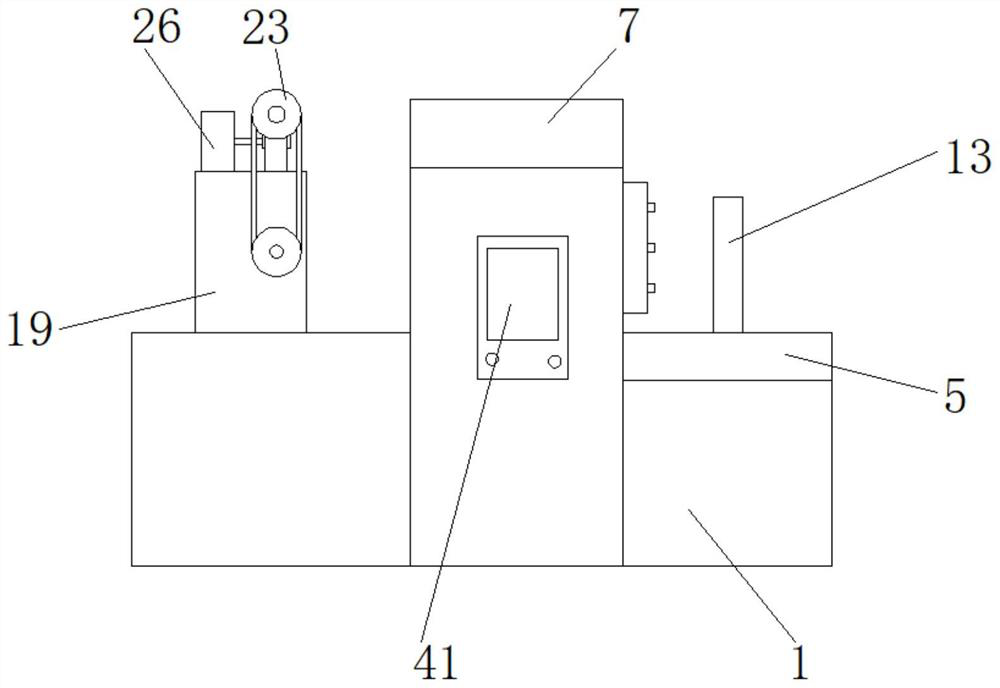

Winding device and method for improving appearance of cast film

The invention discloses a winding device for improving the appearance of a cast film. The winding device sequentially comprises an extruder, a melt filter, a die head, a cooling roller, a transition roller, a thickness gauge, a side cutting station, a corona device, a storage mechanism, a tensioning roller, a sliding cutter, a winding compression roller, a film winding shaft and a winding shaft frame from left to right. The cooling roller is located under the die head, the linear speed of the cooling roller is the same as that of the transition roller, and tension sensors are arranged at the two ends of the storage mechanism. By improving the operation method of a winding system of a cast film production line, the aims that the effect that a wound pipe bottom film is free of lotus leaf edges, wrinkles and bubbles is achieved, the winding quality is improved, the film quality is improved, and waste of the pipe bottom film is reduced are achieved.

Owner:罗文峰

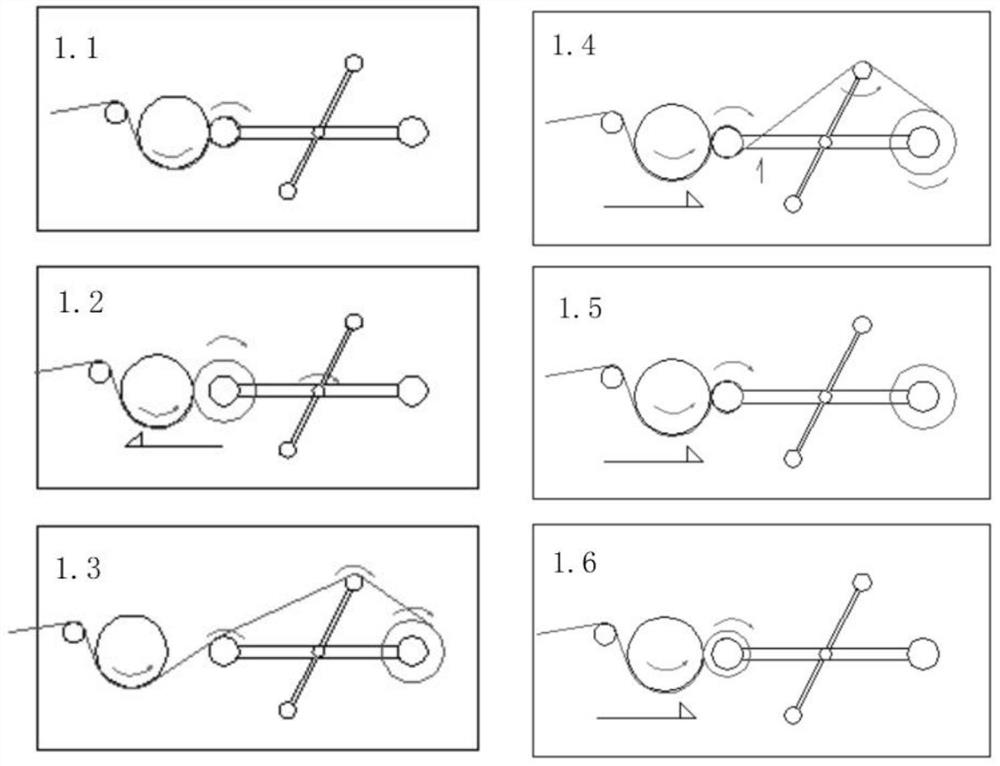

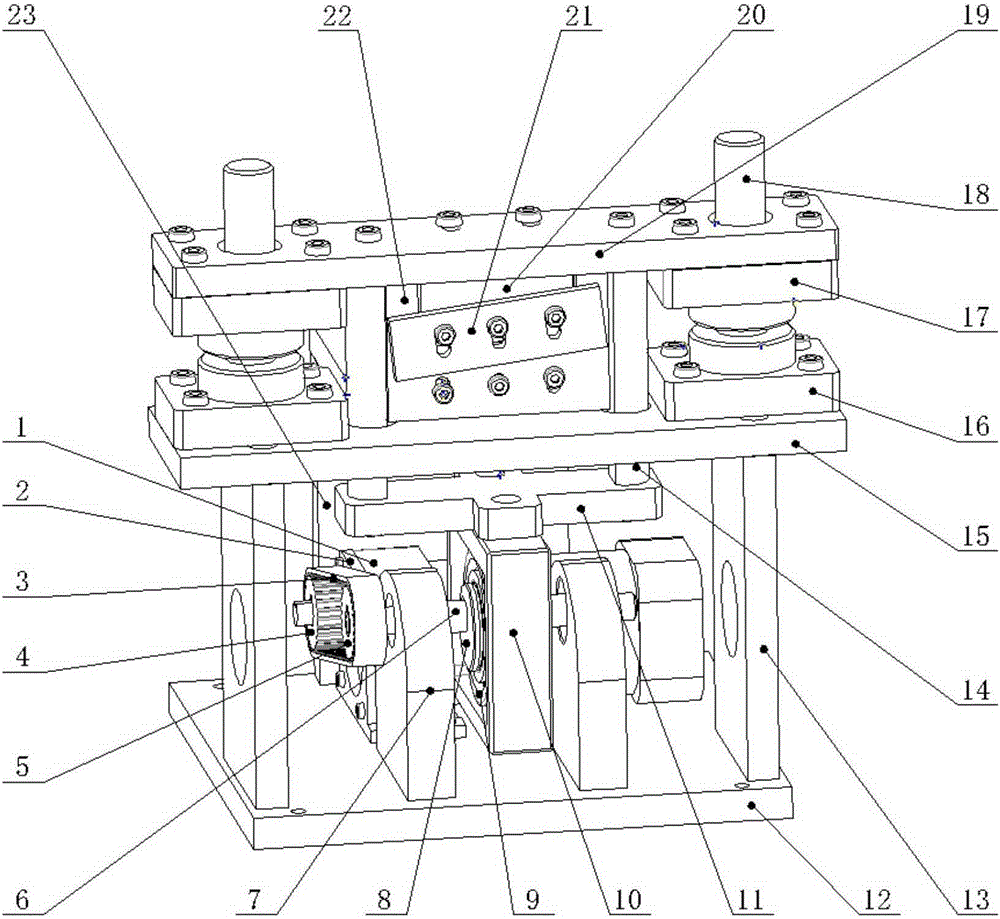

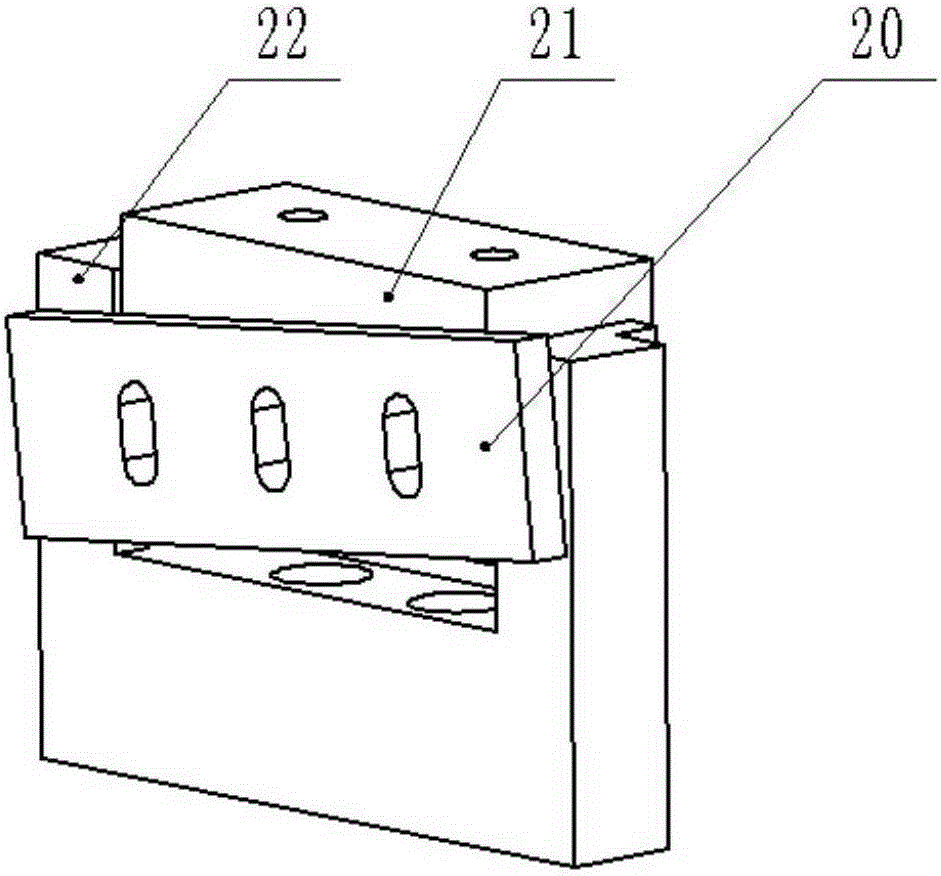

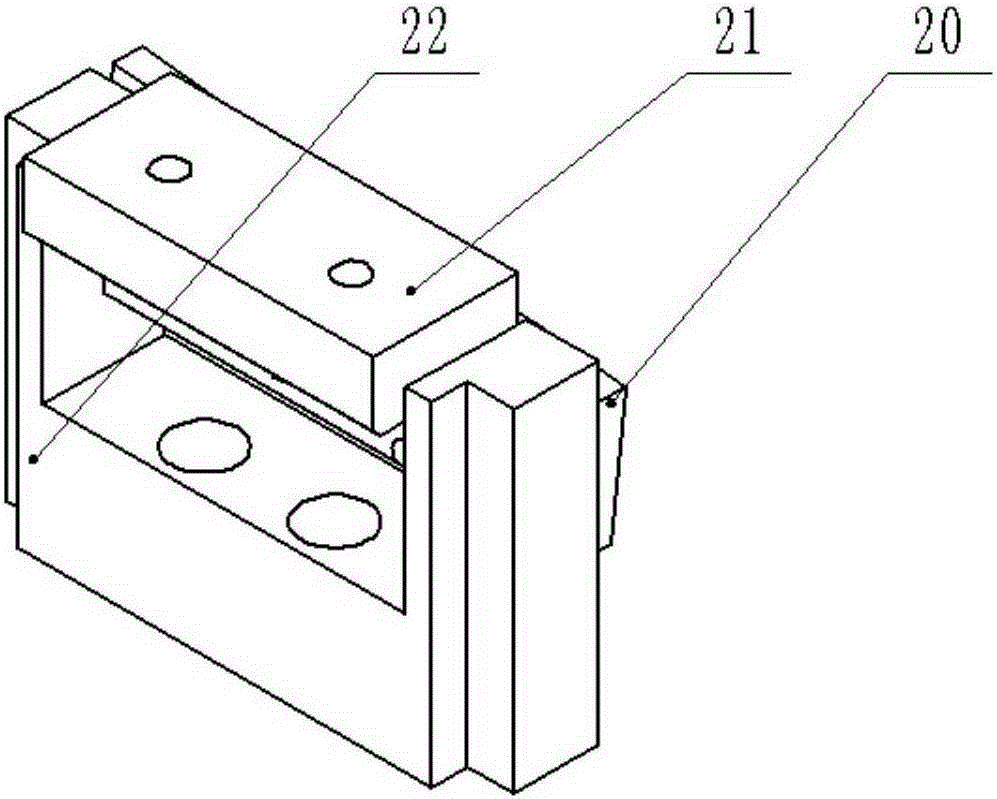

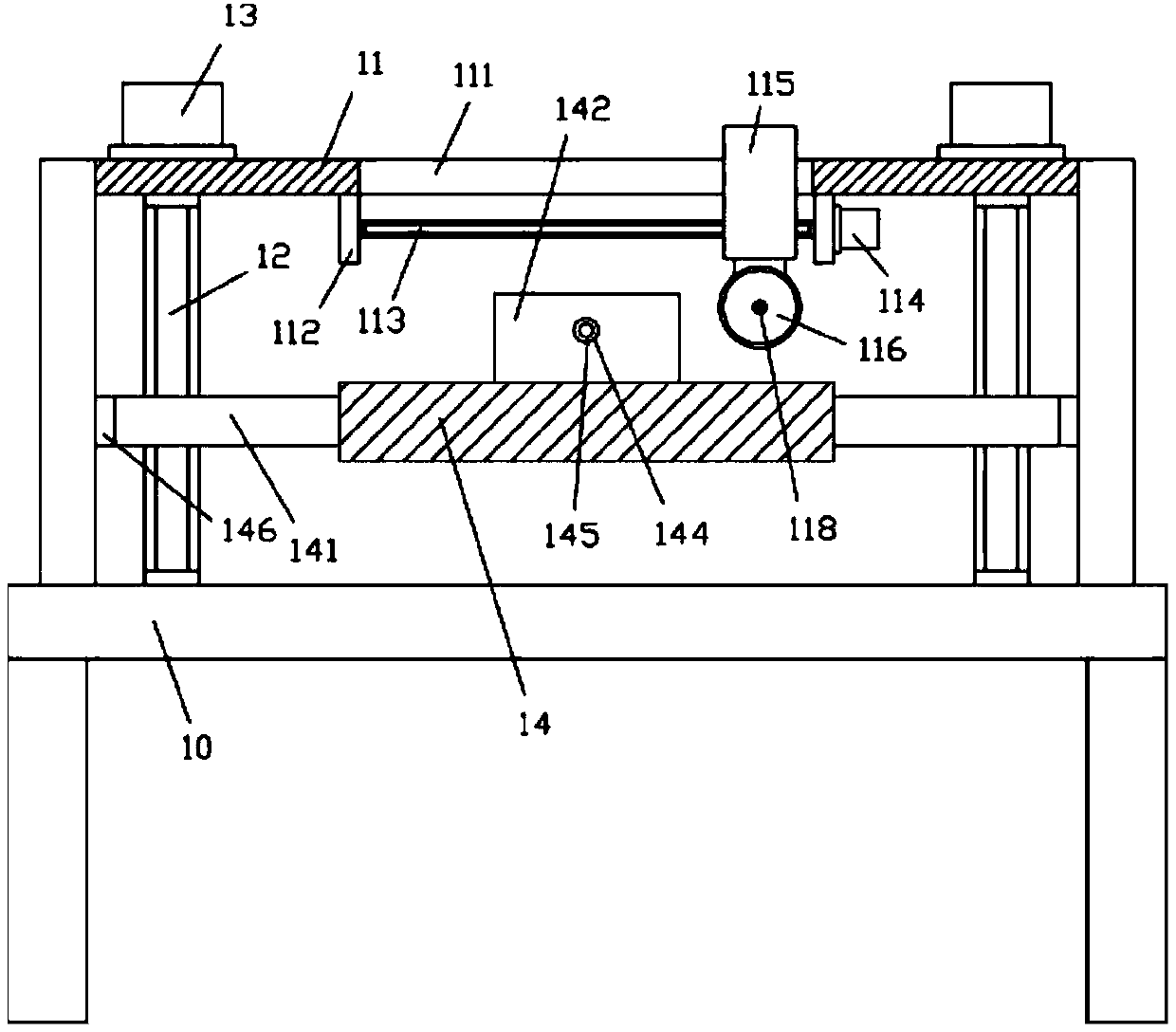

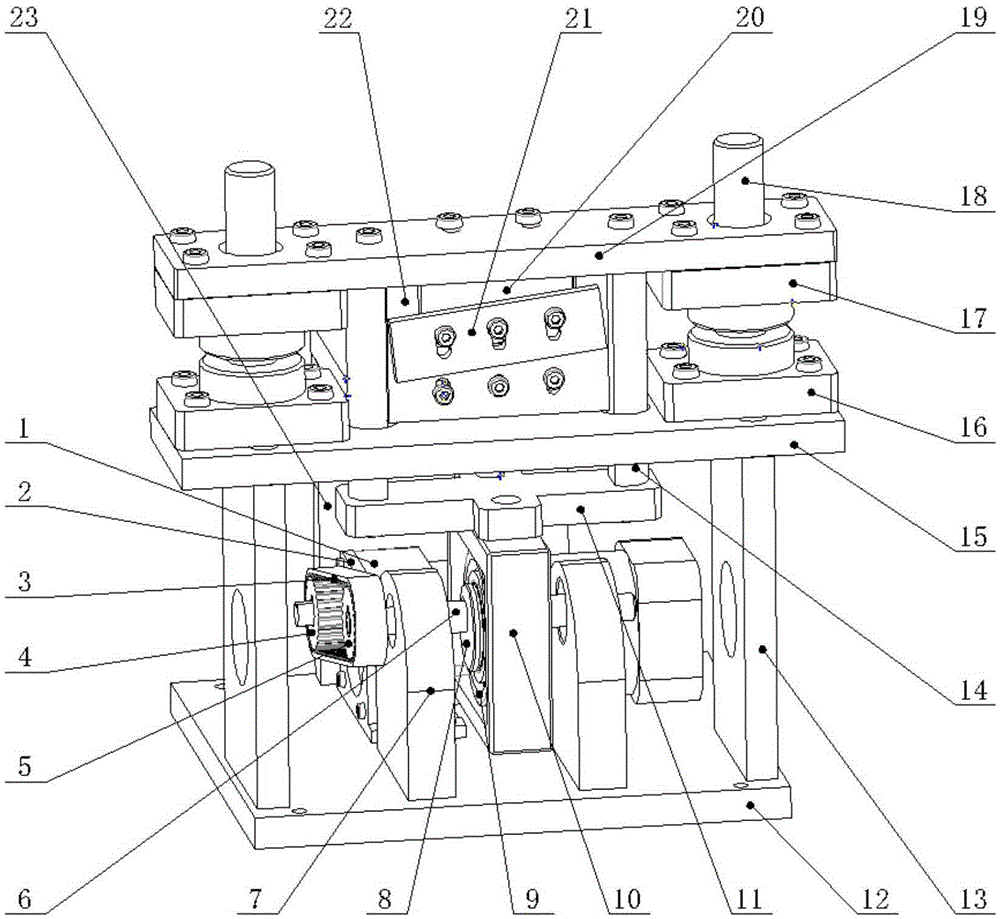

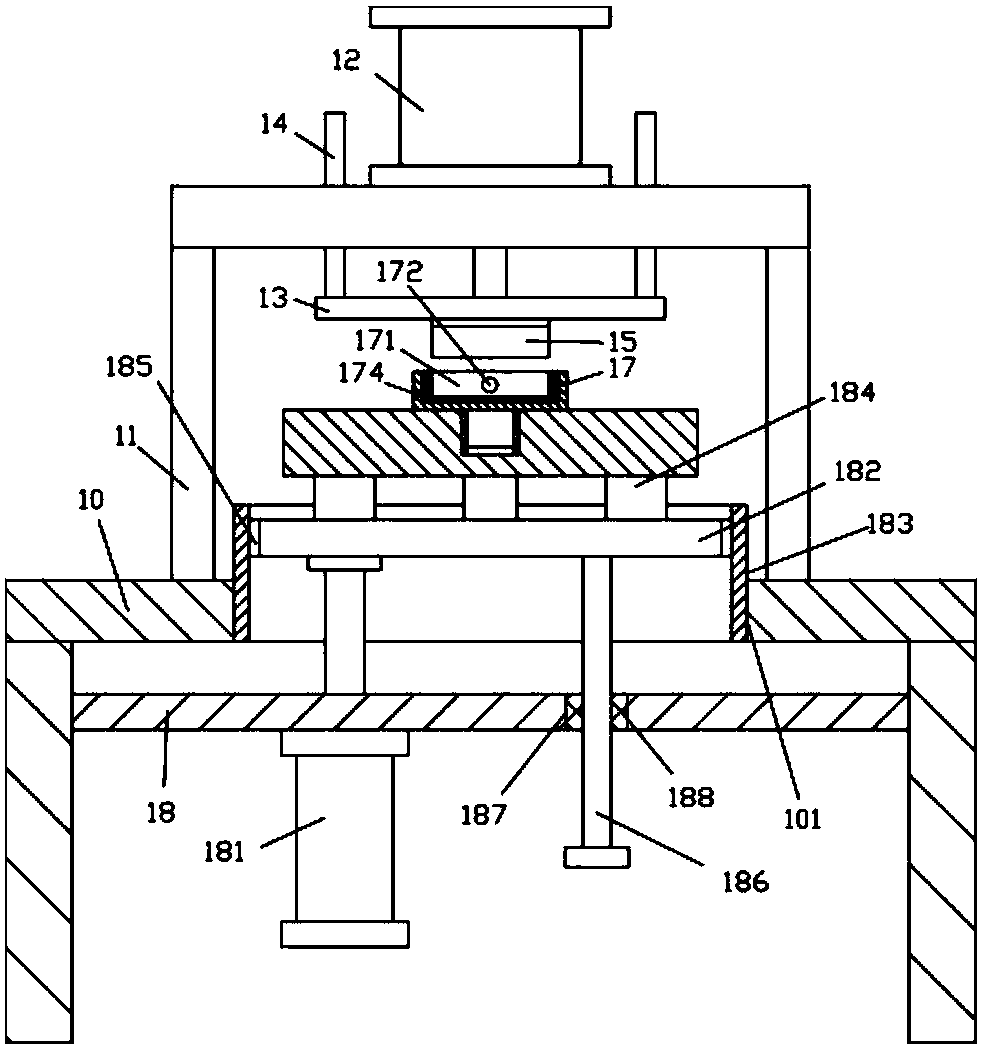

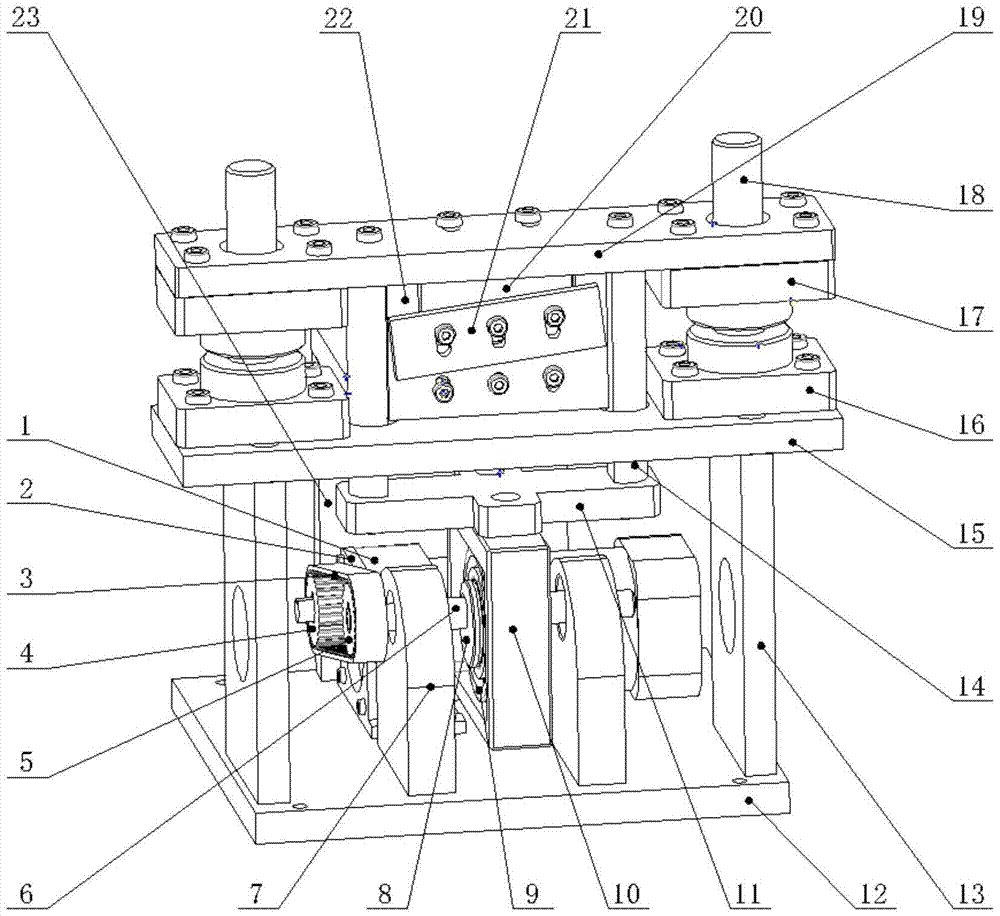

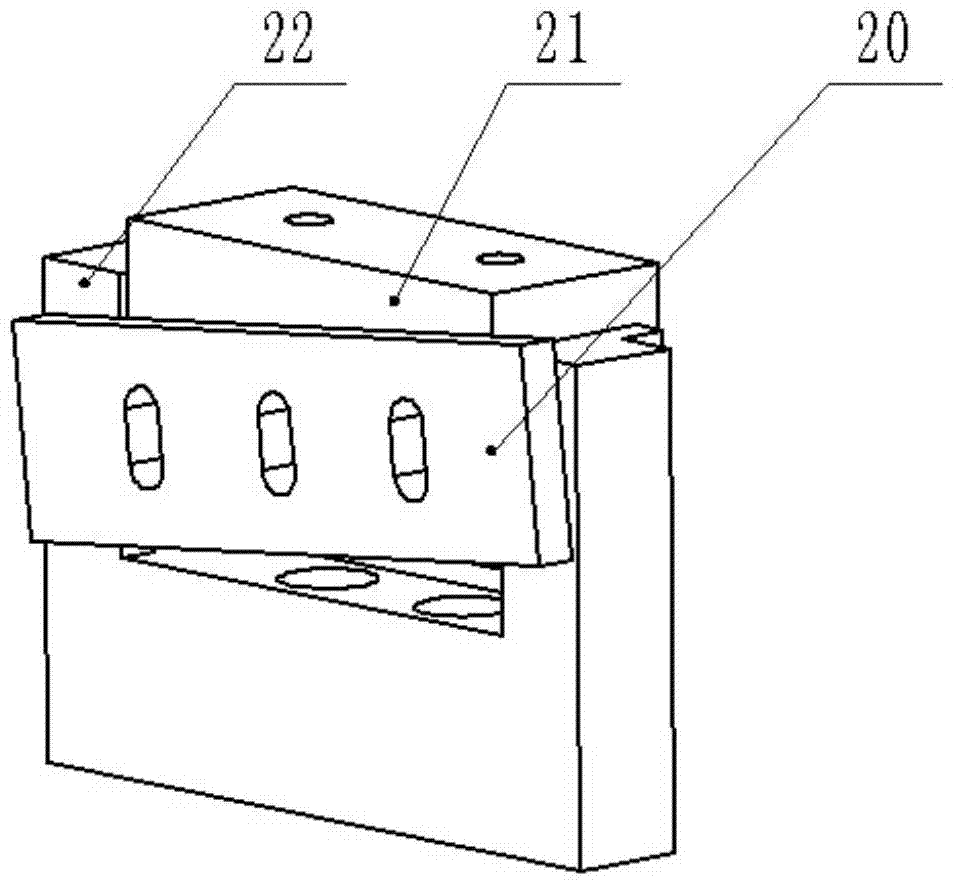

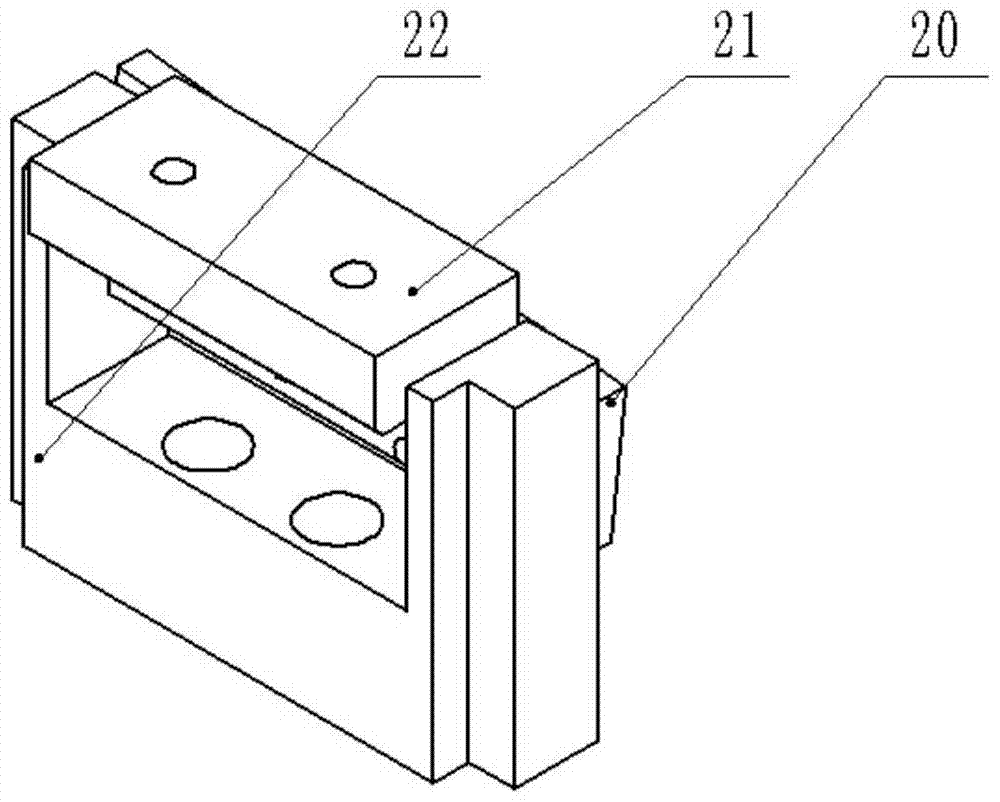

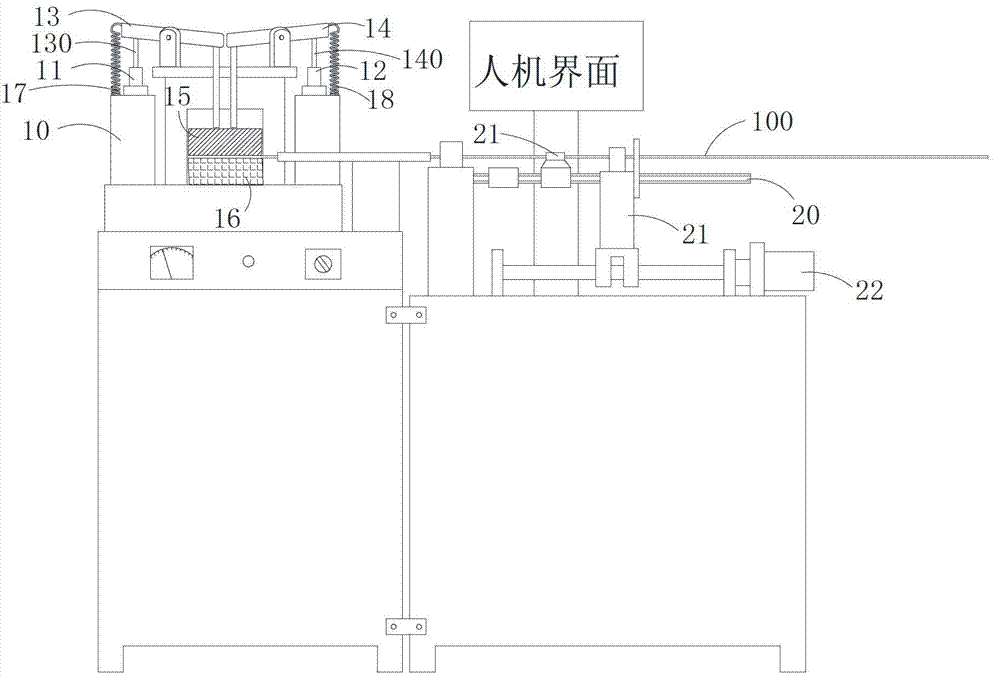

Metal sheet cutting off machine

ActiveCN105328255AReduce gapAvoid Knife Collision SituationsShearing machinesShearing machine accessoriesDrive shaftMetal sheet

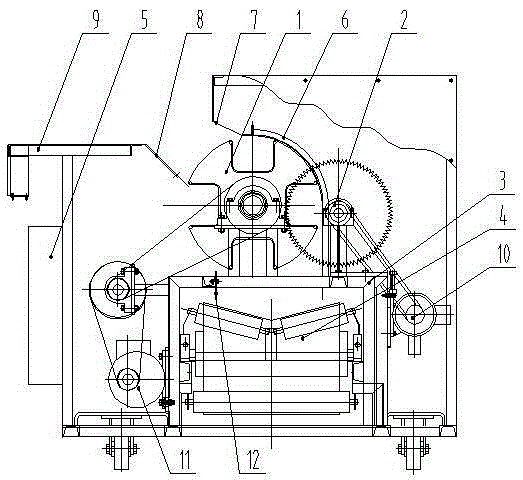

The invention discloses a metal sheet cutting off machine which comprises an automatic feeding component and a cutting off component, wherein the automatic feeding component is transmitted through a synchronous wheel synchronous belt by a servo motor, and a feeding rubber roll and a press roll are driven to precisely rotate according to the feeding length; metal sheet strips pressed between the feeding rubber roll and the press roll are precisely transported forwards under the guidance of a feeding guide component, so that the automatic feeding function of the cutting off machine is achieved; a motor provides powder for the cutting off component; under the transmission of a circle-arc tooth synchronous belt and a transmission shaft side circle-arc tooth synchronous wheel, an eccentric wheel on a transmission shaft is driven to rotate to perform eccentric motion, and a bearing drives and acts on a frame body; and finally, a cutter is driven to perform rectilinear motion up and down under the guidance function of the guide component, so that the metal sheet strips are cut off. According to the metal sheet cutting off machine, a plurality of metal sheet strips can be automatically fed and cut off at the same time, the working efficiency is high, the cutter is easy to mount, the length accuracy is high after cutting, and the fracture is neat.

Owner:NANJING INST OF TECH

Rotary cable cutting mechanism with serrated blades

InactiveCN107755600ANeat fractureConvenient for manual packagingArchitectural engineeringDrive motor

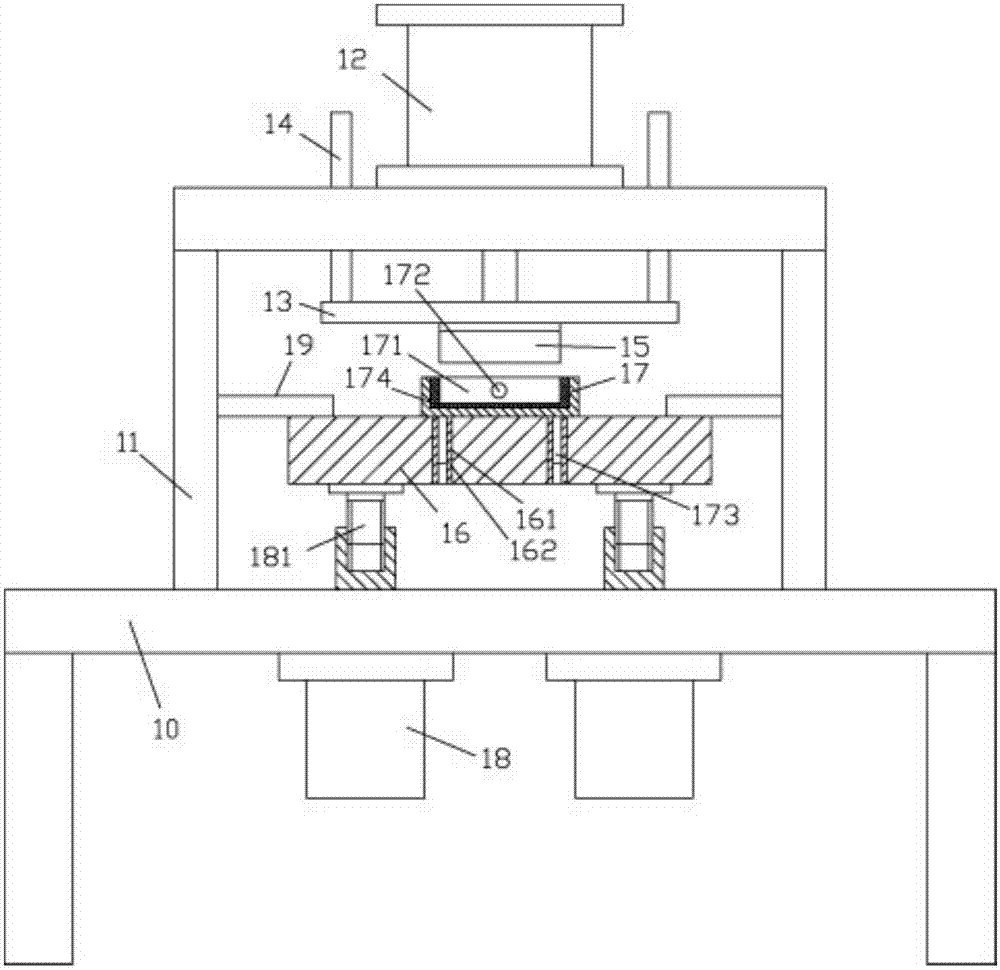

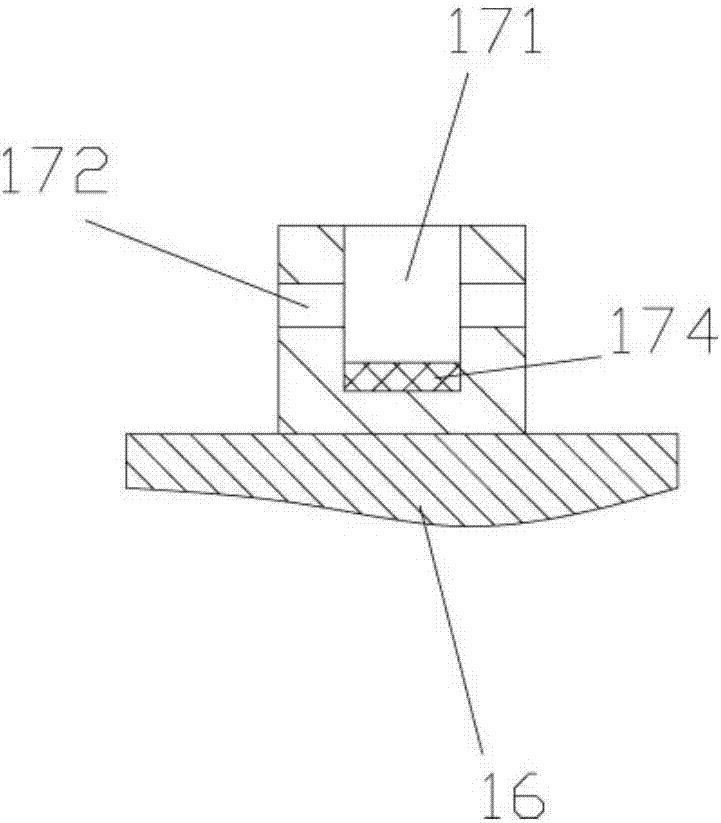

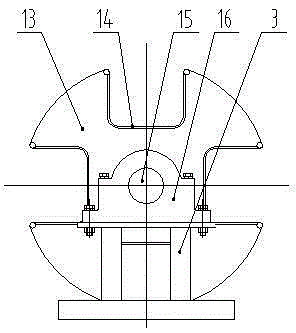

The invention discloses a toothed blade rotary cable cutting mechanism, which comprises a frame, an upper support frame is fixed on the top surface of the top plate of the frame, and vertical screw rods are arranged on both sides of the top plate of the upper support frame. The bottom end of the screw rod is hinged on the top plate of the frame, the top end of the vertical screw rod is hinged on the top plate of the upper support frame, the bottom end of the vertical screw rod is hinged on the top plate of the frame, and the two driving motors are fixed on the top plate of the upper support frame On both sides of the top surface, the output shaft of the driving motor is a spline shaft, and the spline shaft is inserted into the spline hole at the top of the vertical screw rod. The lifting plate is between the two vertical screw rods. A connecting block is fixed on the side, and the connecting block is screwed into the corresponding vertical screw. Two limiting blocks are fixed in the middle of the top surface of the lifting plate. There is a cutting through groove between the two limiting blocks. The middle part has threading through holes corresponding to the front and back. The invention can automatically cut the electric wires and cables, the fracture is neat, convenient for manual packaging and use, and has good effect.

Owner:SUZHOU CHENZHONG AUTOMATIC TECH CO LTD

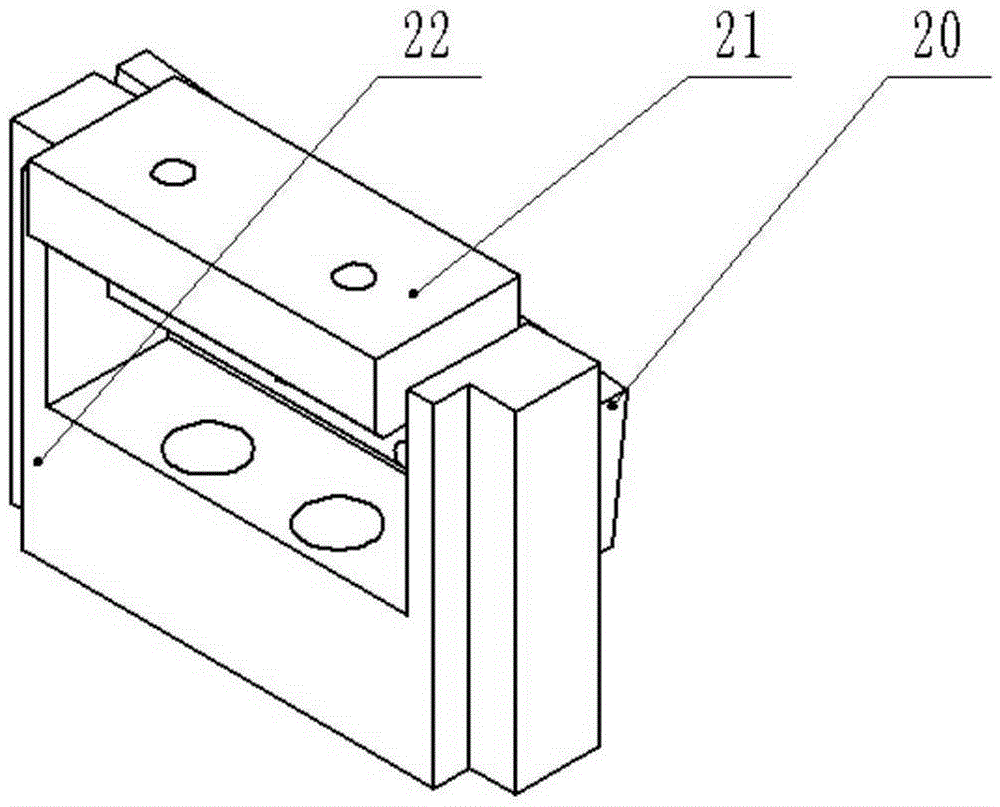

Cut-off device of metal sheet cut-off machine

The invention discloses a cut-off device of a metal sheet cut-off machine. The cut-off device of the metal sheet cut-off machine comprises a cut-off power driving assembly, a cut-off guiding part and a cut-off execution assembly; a motor provides power for the cut-off device integrally; an eccentric wheel on a driving shaft is driven to rotate through driving of synchronous wheels and a synchronous belt; eccentric movement acts on a framework through bearing driving; meanwhile, under the guiding action of the guiding part, a cutter is finally driven to perform vertical linear cut-off movement. By means of the cut-off device of the metal sheet cut-off machine, multiple metal sheets can be cut off at the same time; the cutter is convenient to mount; the work efficiency and cut-off size accuracy are high; cut notches are neat; manual assistance is not needed during cut-off action; control is simple; the cost is low.

Owner:NANJING INST OF TECH

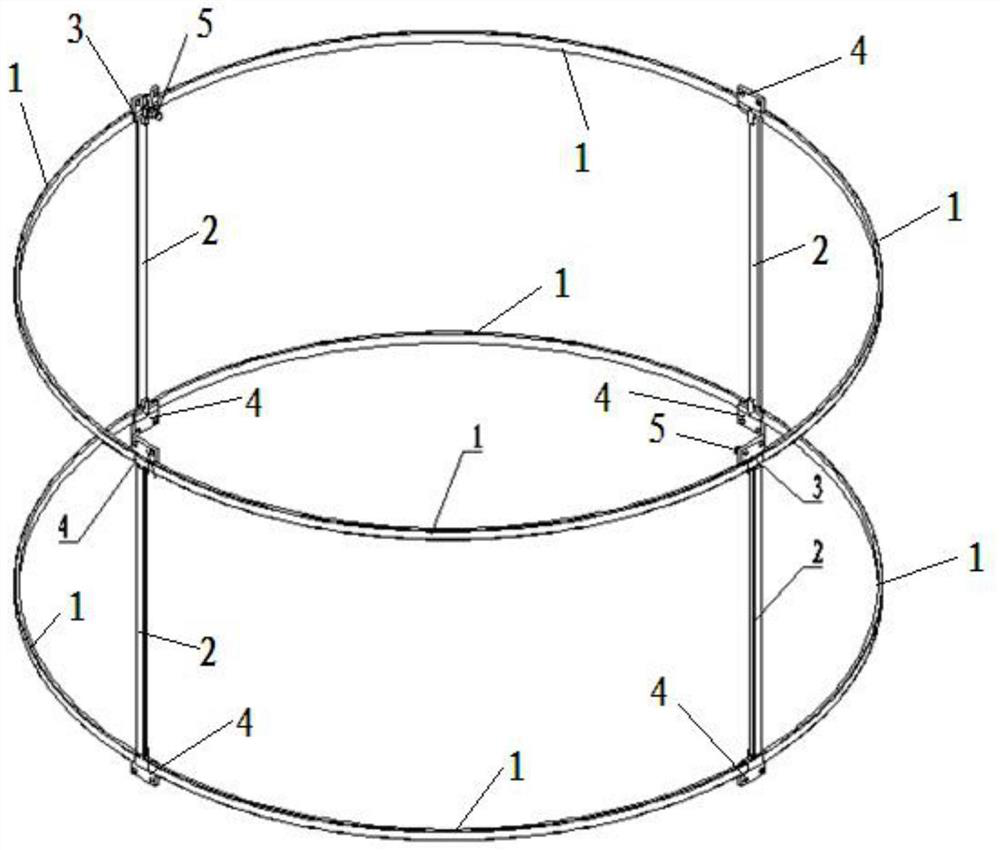

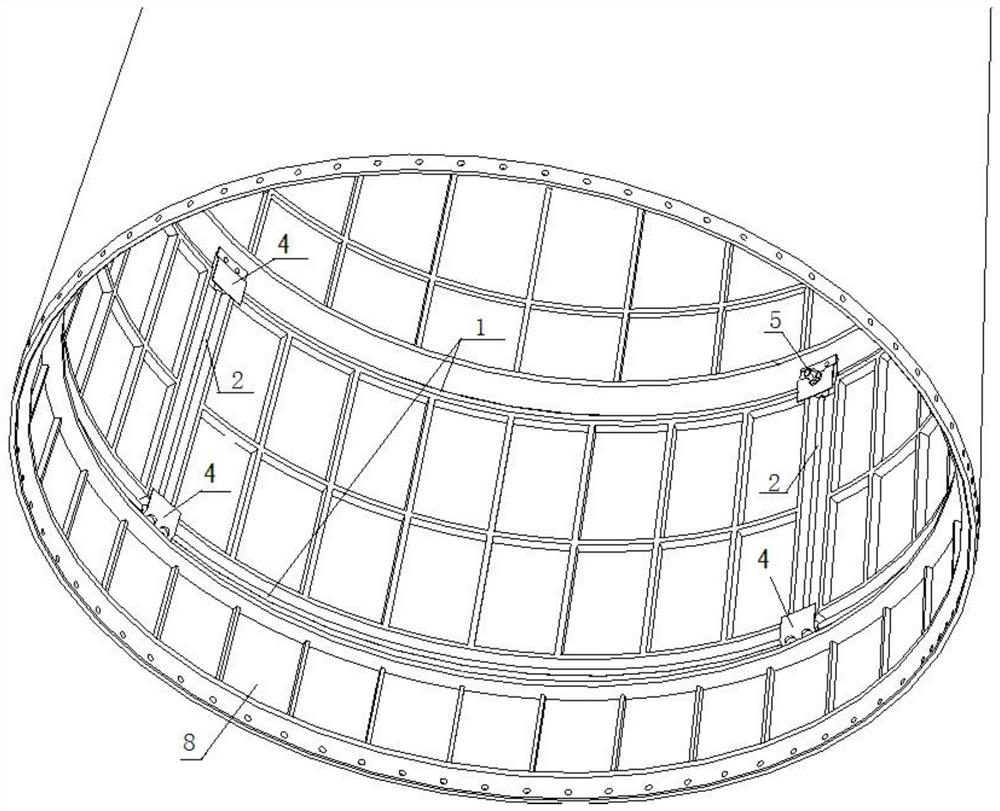

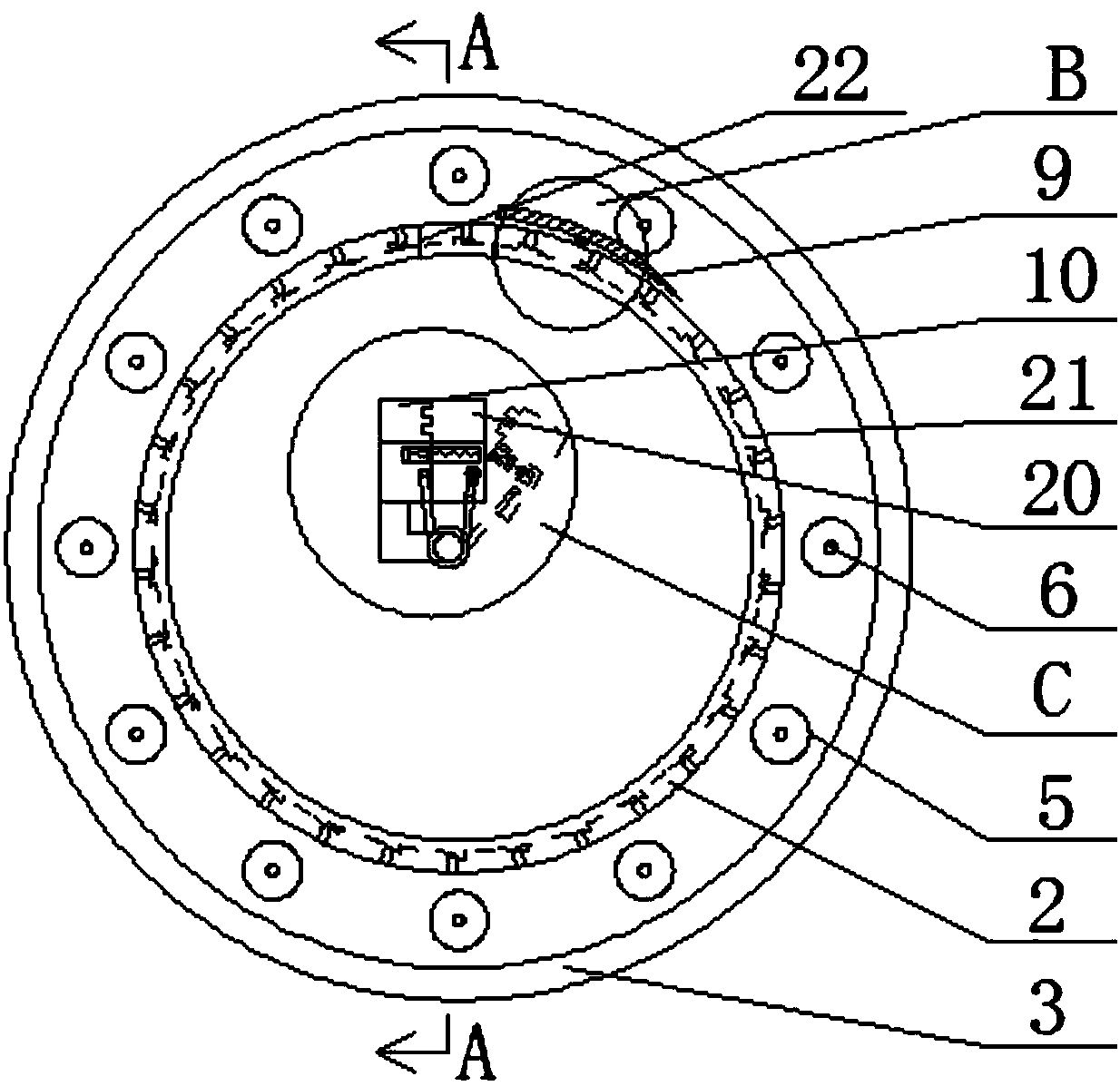

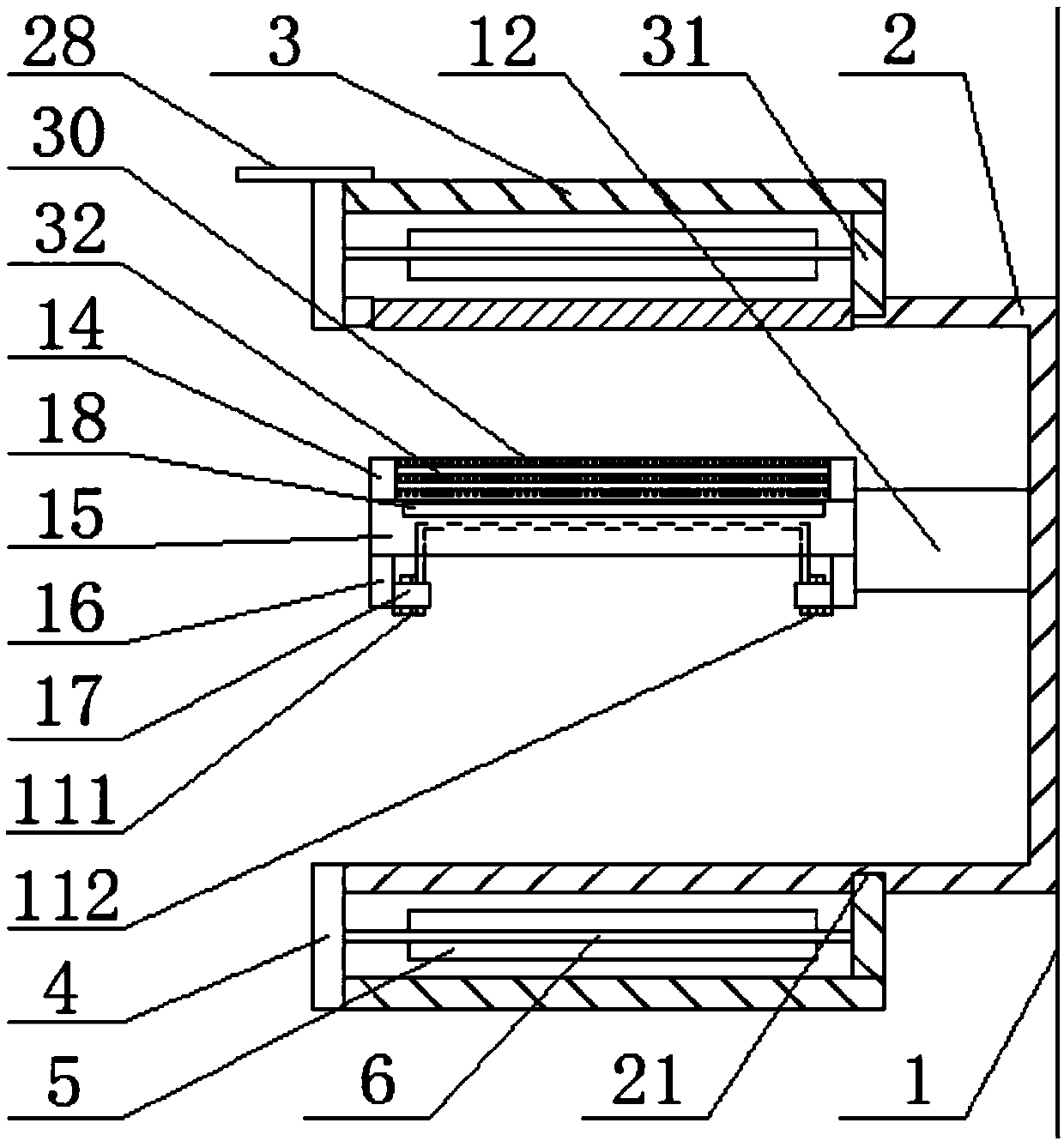

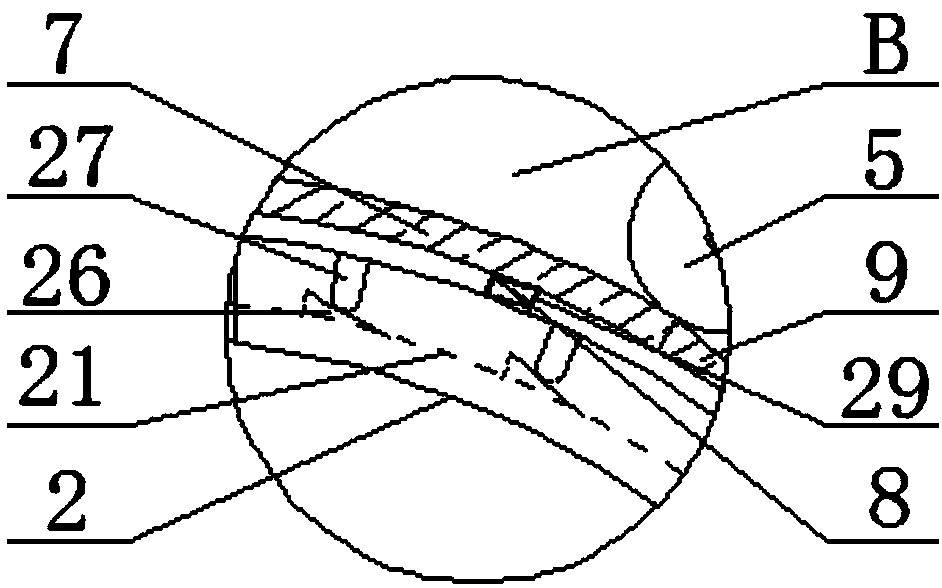

Large-thickness separation structure without weakening groove, stress concentration or protective cover

ActiveCN113525726AImprove bearing efficiencyNeat fractureCosmonautic vehiclesCosmonautic component separationDetonatorStress concentration

The invention relates to a large-thickness separation structure without a weakening groove, stress concentration or a protective cover, and belongs to the technical field of spacecraft structures. The structure comprises eight annular energy-gathered cutting rope assemblies, four longitudinal energy-gathered cutting rope assemblies, two four-way detonation assemblies, six three-way detonation propagation assemblies and two detonators. Every four annular energy-gathered cutting rope assemblies are sequentially connected end to end to form an annular structure. The four annular energy-gathered cutting rope assemblies located on the lower annular structure are connected through the four three-way explosion propagation assemblies. The four annular energy-gathered cutting rope assemblies located on the upper annular structure are connected through the two four-way detonating assemblies and the two three-way detonating propagation assemblies. The four longitudinal energy-gathered cutting rope assemblies are axially and vertically arranged between the two annular structures; each exploder is in butt joint communication with one four-way detonating assembly; transverse and longitudinal weakening grooves do not need to be formed, the stress concentration effect is avoided, and reliable structure separation is achieved without X-ray centering inspection and protection cover pressure building.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

Cable cutting-off mechanism

The invention discloses a cable cutting-off mechanism. The cable cutting-off mechanism comprises a rack, wherein an upper support frame is fixed on the top surface of a top plate of the rack; a cutting-off oil cylinder is fixed in the middle of the top surface of the top plate of the upper support frame; a push rod of the cutting-off oil cylinder penetrates through the top plate of the upper support frame, and a cutting-off connecting plate is fixed on the push rod of the cutting-off oil cylinder; a vertical guiding rod is fixed on the top surface of the cutting-off connecting plate, and extends out of the top plate of the upper support frame; a cutting-off knife is fixed in the middle of the bottom surface of the cutting-off connecting plate; a lower lifting block is arranged on the top surface of the top plate of the rack; a cable penetrating block is fixed on the top surface of the lower lifting block; a cutting-off groove is formed in the middle of the top surface of the cable penetrating block; the cutting-off groove is positioned under the cutting-off knife; and penetrating through holes which communicate with each other in the front-back direction are formed in the front wall surface and the rear wall surface of the cutting-off groove. By the cable cutting-off mechanism, a cable can be cut off automatically, a fracture is neat, manual packaging and using are facilitated,the efficiency is high, and the effect is good.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

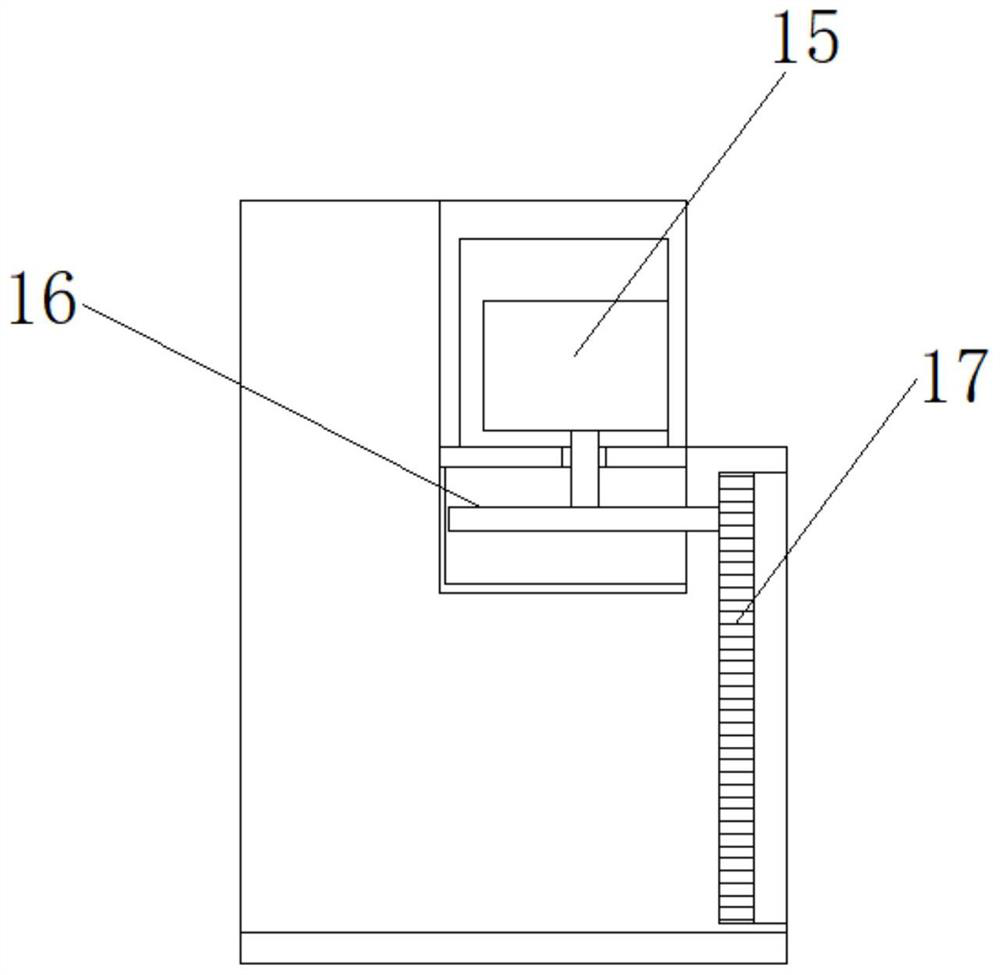

Tissue paper storage device

The invention belongs to the technical field of paper product storage devices and discloses a tissue paper storage device. The tissue paper storage device comprises a double-layer barrel, an inner barrel body is fixed while an outer barrel body is rotatable, and a bottom plate between the two barrel bodies is provided with a limiting shaft for paper roll placement. The top of the inner barrel is provided with a paper outlet, and an unwinding block for driving a paper roll to automatically rotate for unwinding is arranged on one side of the paper outlet. A paper cutting mechanism is arranged inan inner cavity of the inner barrel and comprises a fixed part and a control part, the fixed part and the control part are fixedly connected with two spring sides of a same torsion spring respectively, the fixed part is fixed, the outer end face of the control part is provided with a shifting rod, each of the fixed part and the control part comprises a clamping block and a shear block in verticalconnection, and a cutter driven by a magnet is arranged in each shear block. The tissue paper storage device has advantages that due to high one-time paper storage capacity, frequent replacement is avoided, and labor saving is benefited; owing to a paper cutting function, cut uniformity of paper is realized, accidental tearing is avoided, application is benefited, and paper waste can be reduced;high convenience in use and convenience in popularization and application are achieved.

Owner:张凤

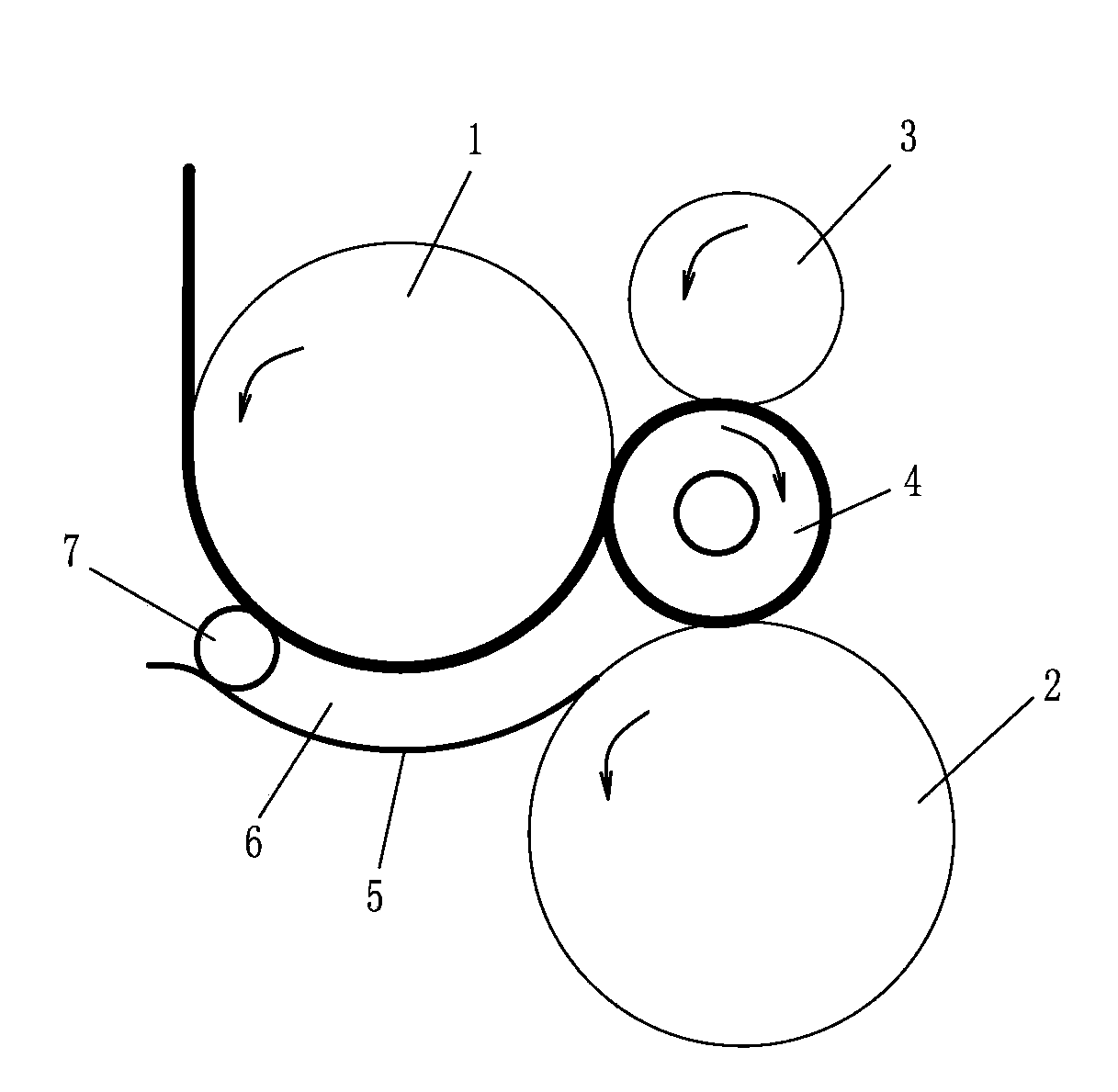

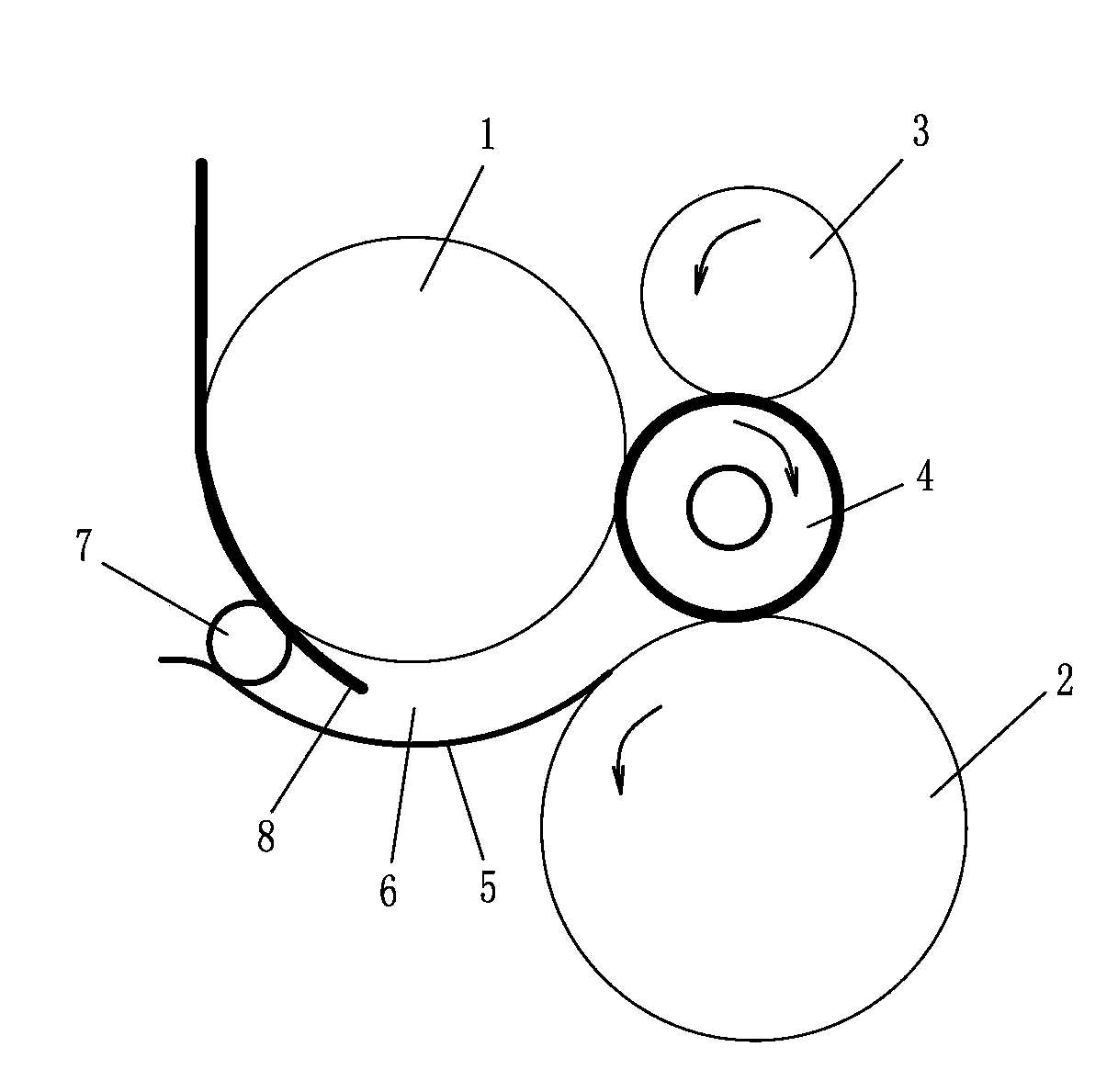

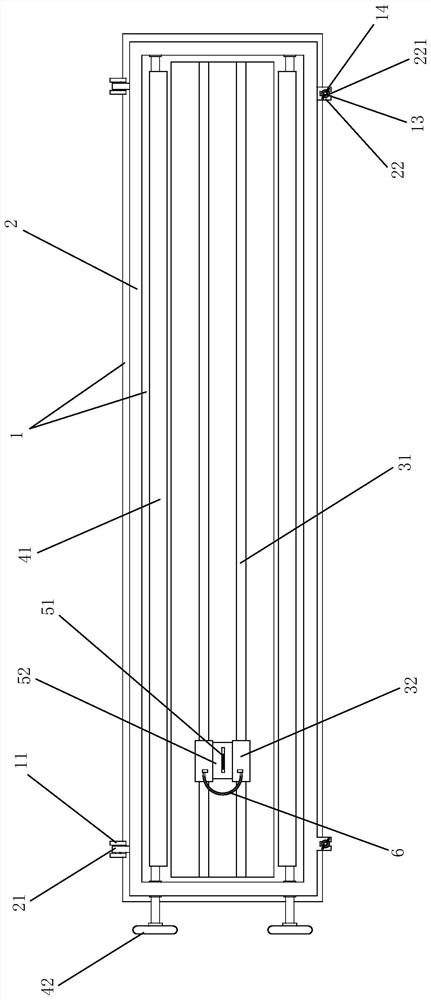

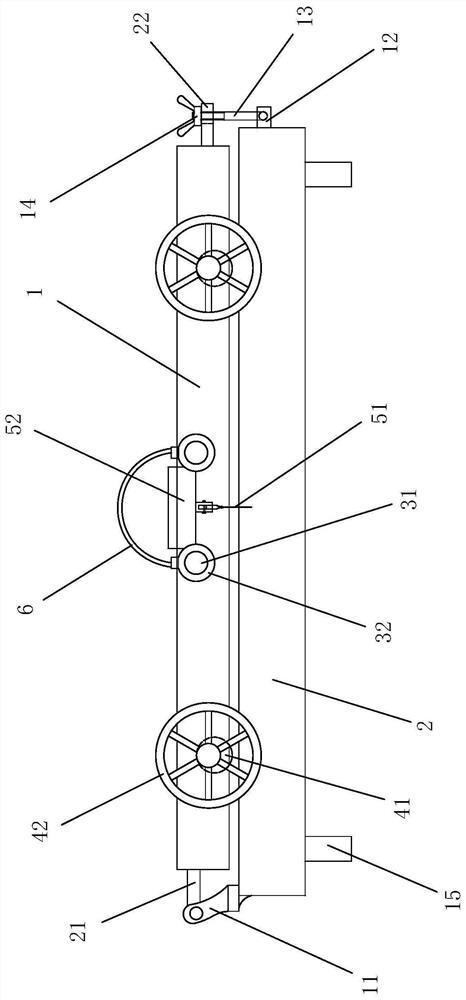

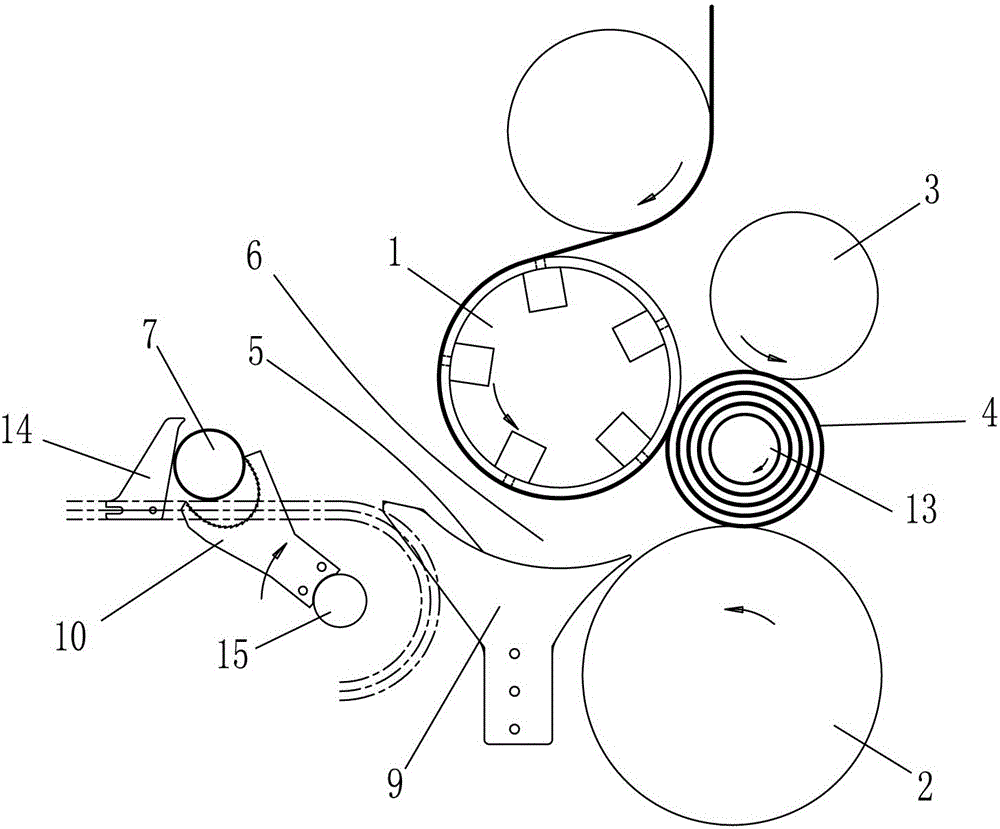

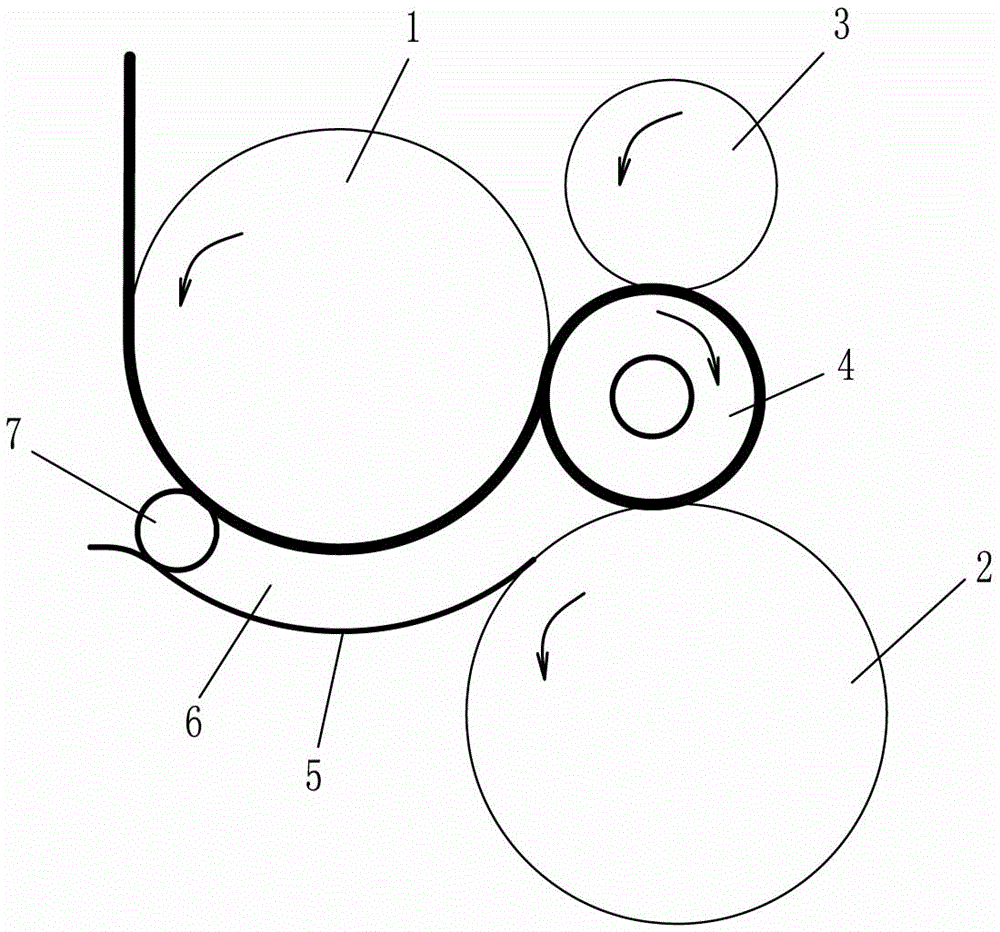

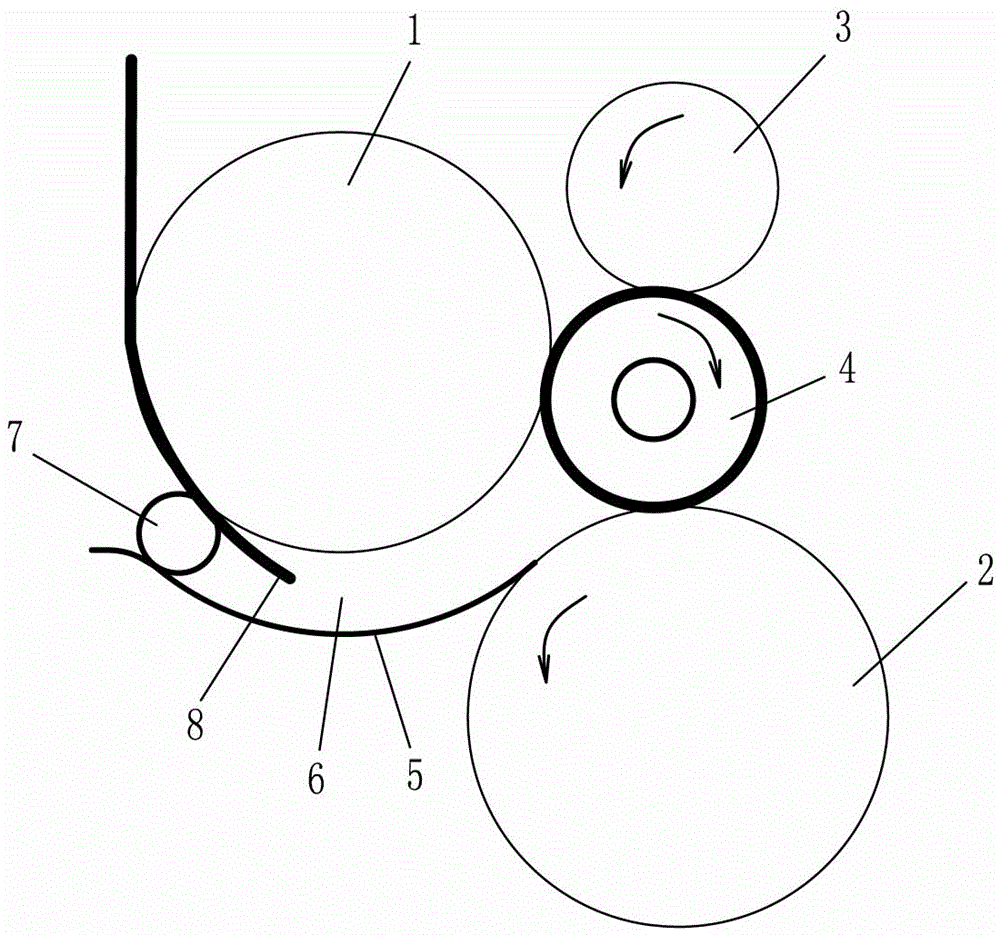

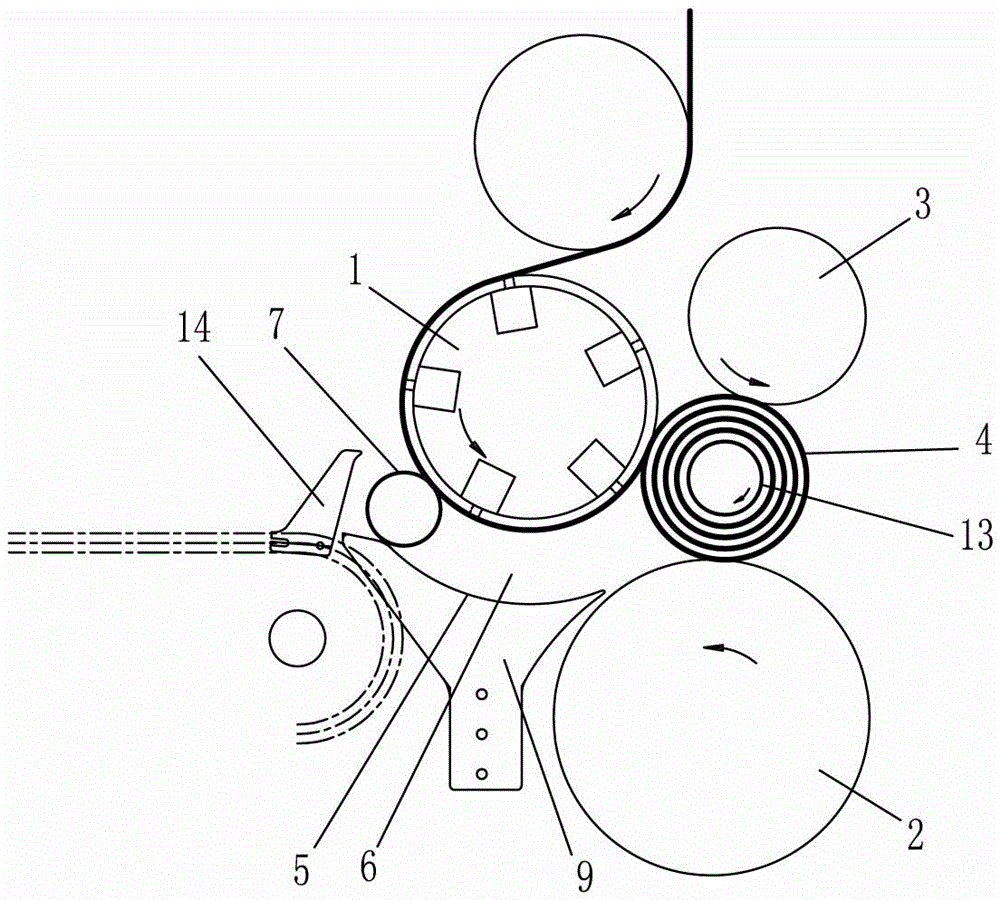

Re-reeling machine capable of reliably and tidily cutting paper

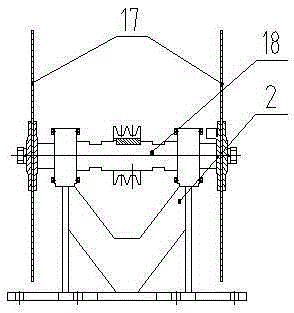

The invention relates to a re-reeling machine capable of reliably and tidily cutting paper. The re-reeling machine comprises an upper re-reeling roller, a bottom re-reeling roller and a paper-pressing roller, which all rotate by clamping a paper scroll, wherein a cylindrical surface of the upper re-reeling roller and a fixed curved surface are close to each other, so as to form a core tube channel, and the cylindrical surface of the upper re-reeling roller is provided with a plurality of circles of smooth surfaces which are slightly protruded from a friction surface of a roller body. The re-reeling machine capable of reliably and tidily cutting paper has the advantages that a core tube cannot be immediately driven to roll by the upper re-reeling roller when the upper re-reeling roller is just pressed by the core tube, so that the paper sheet at the tail of the paper scroll can be reliably broken, the uneven stress on the paper sheet at the tail of the paper scroll caused by the rolling of the core tube is avoided, the fractures of the paper sheet are tidily, and furthermore, when the upper re-reeling roller, the bottom re-reeling roller and the paper-pressing roller all rotate by clamping the paper scroll, the friction surface of the upper re-reeling roller still can be in sufficient contact with the surface of the paper scroll and is not influenced by the smooth surfaces, so that the upper re-reeling roller can reliably rotate at high speed by clamping the paper scroll together with the bottom re-reeling roller and the paper-pressing roller.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

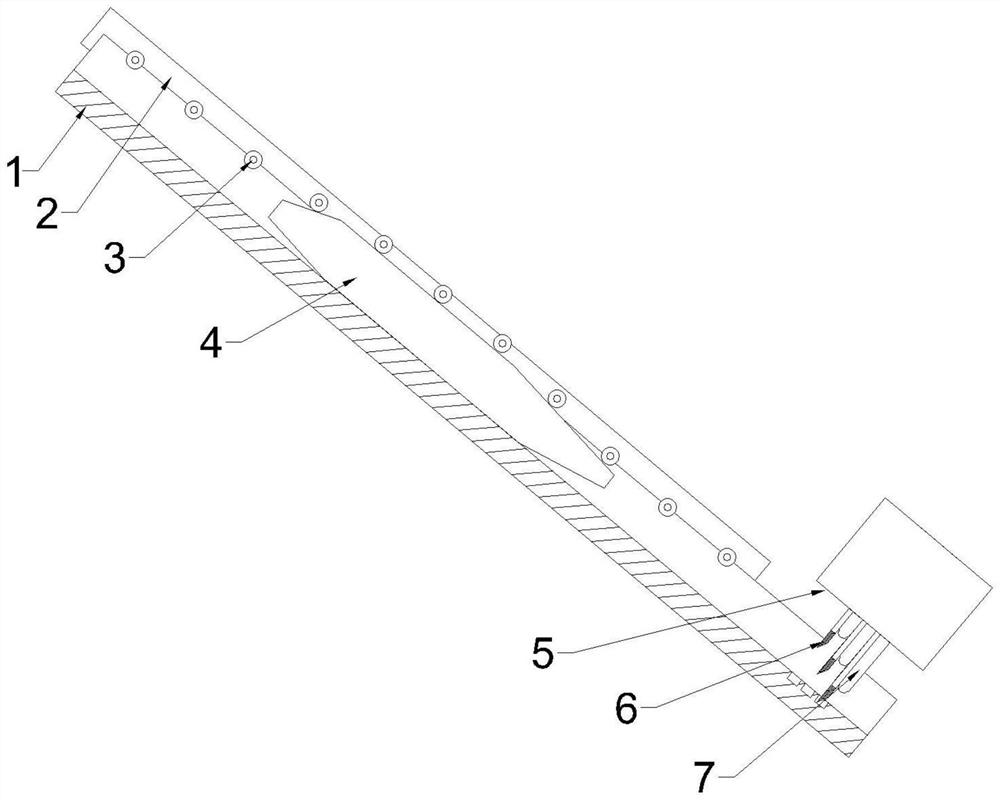

Continuous slicing mechanism for traditional Chinese medicine decoction pieces

InactiveCN113954148ASimple structureQuickly adjust spacingMetal working apparatusEngineeringKnife blades

The invention discloses a continuous slicing mechanism for traditional Chinese medicine decoction pieces. The continuous slicing mechanism comprises a material guiding structure and a slicing structure; the material guiding structure comprises a material guiding slide way and a material guiding cover plate, the material guiding slide way is obliquely arranged and is provided with a downwards-concave arc surface, the material guiding cover plate is a frame plate capable of being buckled on the material guiding slide way, a pressing steel wire with a material guiding assembly is arranged on the frame plate of the material guiding cover plate, and the pressing steel wire of the material guiding assembly can synchronously rotate to assist feeding; an extension part is arranged at the tail end of the material guiding slide way, the slicing structure is arranged at the extension part and comprises a cylindrical tool apron, multiple groups of cutting units are arranged on the cylindrical tool apron, the cutting units are overlapped up and down through an assembly frame and are provided with cutting blades and gaskets, and the cutting blades and the gaskets in the same group and the cutting blades in different groups are arranged in a staggered mode. By the aid of the continuous slicing mechanism, continuous slicing processing of traditional Chinese medicinal materials can be realized, multiple slices can be discharged at a time, and the slicing thickness can be conveniently and quickly adjusted.

Owner:怀化市康隆中药材开发有限公司

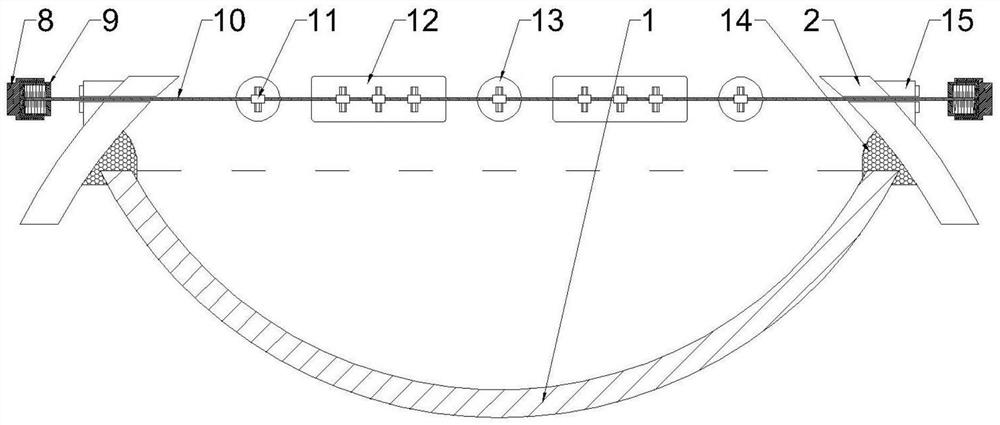

Electric pole rotary cutter

The invention relates to the field of electric power facilities, and particularly discloses an electric pole rotary cutter. The electric pole rotary cutter comprises two sections of arc-shaped sliding rails of which one ends are hinged together, the other ends of the two sections of arc-shaped sliding rails are each provided with a handle, each handle is provided with a fixing hole, and each fixing hole is provided with a fastening piece in a matched mode; the inner side and the outer side of one arc-shaped sliding rail are provided with inner pulleys and outer pulleys respectively, a sliding plate is fixedly arranged on the inner pulleys and the outer pulleys and provided with a motor capable of doing rectilinear motion in the radial direction of the arc-shaped sliding rails, and the output end of the motor is downwards and fixedly provided with a circular cutter. According to the electric pole rotary cutter, due to the fact that the circular cuter controlled by the motor is arranged, when the two arc-shaped sliding rails clamp an electric pole, cutting is performed by changing the position of the motor, electric pole cutting automation is achieved, artificial cutter trouble is avoided, effort and labor are saved, a fracture is neat, secondary flattening is not needed, and therefore the working efficiency is greatly improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Spent fuel rod cutting device and method

The invention discloses a spent fuel rod cutting device and method. The spent fuel rod cutting device comprises a pipe cutter, a flow guiding cover, a pipe sleeve, a filter, a low-pressure blower and an ejector rod. Two holes are formed in the side wall of the flow guiding cover. The pipe cutter is arranged in the flow guiding cover. The flow guiding cover is connected with the pipe sleeve. The ejector rod and the flow guiding cover holes are on the same horizontal line. The filter is arranged between the flow guiding cover and the low-pressure blower. The spent fuel rod cutting method comprises the following steps that (1) all the components are connected, and the position height is adjusted; (2) the pipe cutter and a spent fuel rod are arranged in suitable positions; (3) cutting is conducted; and (4) a cutting port is sleeved with a protective sleeve. According to the spent fuel rod cutting device and method provided by the invention, remote operation can be conducted, the structure is simple, the occupied space is small, the reliability is high, cutting environment radioactive substance pollution diffusion can be effectively controlled, and the hot chamber operation cost is reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Jujun grass seedling preparing machine

The invention relates to processing equipment of jujun grass seedlings, and belongs to the technical field of animal husbandry machinery. A cutting mechanism is arranged on one side of a feeding mechanism, saw blades on the cutting mechanism are arranged between two material guiding discs arranged on the feeding mechanism, saw teeth of the saw blades at least stretch into the bottoms of material guiding grooves formed in the material guiding discs or coincide with the bottom edges of the material guiding grooves, the rotating direction of the saw blades is reverse to that of the material guiding discs, and the feeding mechanism feeds the jujun grass seedlings which are cut into segments into a material collecting groove through the cutting mechanism or outputs the jujun grass seedlings through a conveying mechanism. According to the jujun grass seedling preparing machine, the structure is simple, the processed jujun grass seedlings are uniform in fracture and identical in length, and mechanized planting is convenient; the processing labor intensity is low, and the efficiency is high; equipment safety protection is complete, and operation is safe and convenient. The jujun grass seedling preparing machine also can be used for processing seedlings of other rhizome plants and has the great application prospect.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Electric wire and cable cutting-off device with buffering mechanism

The invention discloses an electric wire and cable cutting-off device with a buffering mechanism. The electric wire and cable cutting-off device comprises a rack, and an upper supporting frame is fixed to the top face of a top plate of the rack. A lower transverse plate is arranged below the top plate of the rack, the two sides of the lower transverse plate are fixed to two lower supporting side plates of the rack, and a lifting air cylinder is fixed to the middle of the bottom face of the lower transverse plate. A pushing rod of the lifting air cylinder penetrates through the lower transverseplate and is fixedly provided with a lifting main plate, the lifting main plate is arranged in a guiding sleeve body in inserted and sleeved modes, and the guiding sleeve body is arranged in a centerthrough groove formed in the middle of the top plate of the rack in inserted and sleeved modes. The outer side wall of the guiding sleeve body is fixed to the inner side wall of the center through groove, and the top end of the guiding sleeve body extends upwards to extend out of the top plate of the rack. A plurality if elastic transitional blocks are fixed to the top face of the lifting main board, and the bottom face of a lower lifting block is fixed to the top faces of the elastic transitional blocks. According to the electric wire and cable cutting-off device, electric wires and cables can be automatically cut off, cut openings are tidy, manual packing for using is facilitated, the efficiency is high, and the effect is good.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

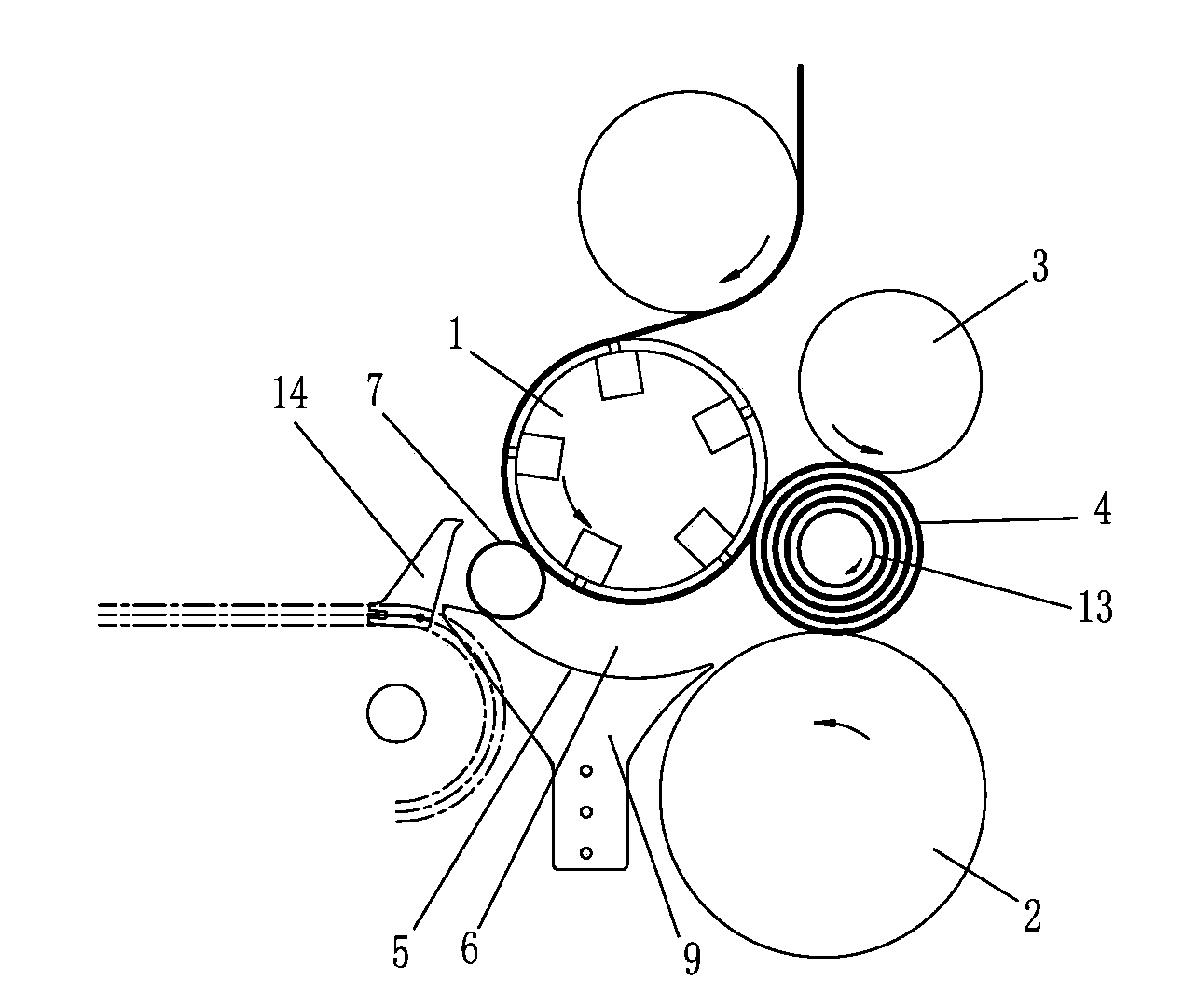

Wide zero-speed material replacing and splicing system and replacing and splicing method

InactiveCN102069604BMeet needsReduce weightPaper/cardboard articlesProgrammable logic controllerEngineering

Owner:HANGZHOU CREATOR MACHINERY MFG

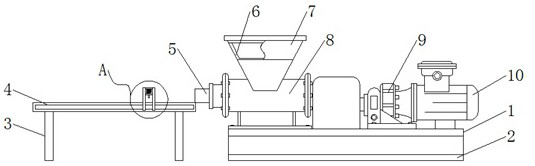

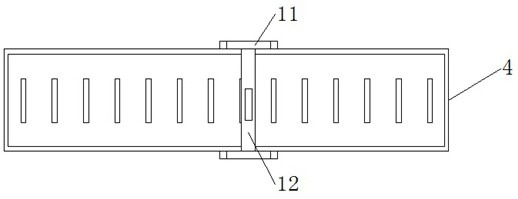

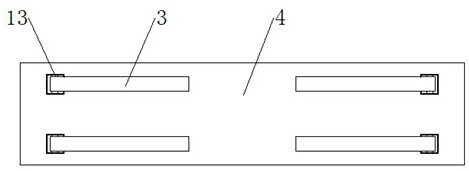

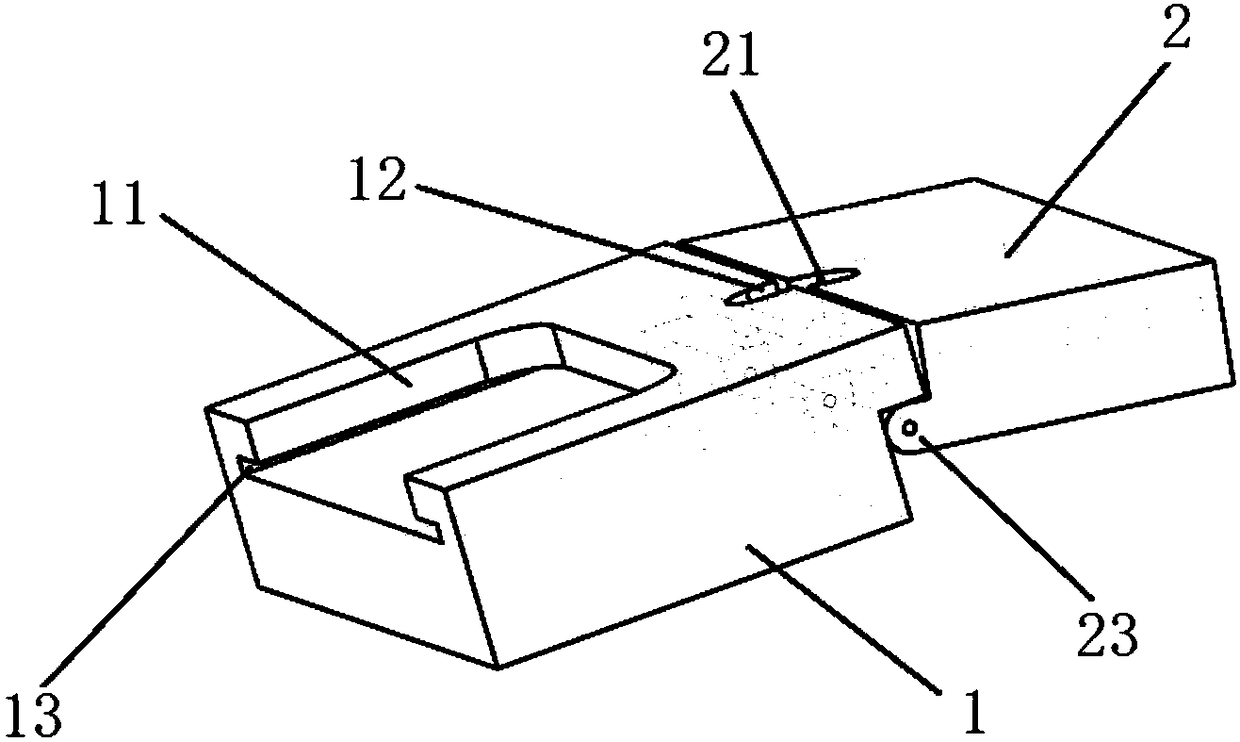

Mining stemming machine convenient for cutting materials

The invention discloses a mining stemming machine convenient for material cutting. The machine comprises a machine body and a bearing plate. A machine base is arranged at the bottom end of the machinebody and fixedly connected with the machine body, a motor is arranged at the right end of the upper part of the machine base and fixedly connected with the machine base in a threaded connection manner, a speed reducer is arranged on the left side of the motor, and the speed reducer is fixed to the machine base in a screw joint manner. An installation base can move on the bearing plate through a sliding groove formed in the bearing plate, a return spring is arranged above a stemming cutting blade; after the stemming cutting blade is pressed downwards to cut off stemming, the return spring canautomatically retract the cutting blade, then the stemming cutting blade is more convenient to use, the cut of the stemming is more orderly after the stemming cutting blade passes through the stemming, a graduated bar is arranged on the bearing plate, stemming can be cut into sections more evenly through the graduated bar, the production quality and the production efficiency of the stemming are improved, and a user can cut the stemming into sections more conveniently.

Owner:徐州中泰生物科技有限公司

Conducting glass edge breaking device

InactiveCN108503208ADon't worry about damageAvoid damageGlass severing apparatusEngineeringElectrical and Electronics engineering

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Broach for belt cutting

InactiveCN111844148AReduce labor intensityAvoid scratchesMetal working apparatusEngineeringStructural engineering

The invention discloses a broach for belt cutting. The broach comprises a bottom frame, a movable frame, a guide mechanism, a clamping mechanism and a blade assembly. The movable frame is located above the bottom frame. The left side of the movable frame is rotationally connected with the bottom frame, and the right side of the movable frame is detachably and fixedly connected with the bottom frame. The guide mechanism is arranged in the movable frame and comprises two guide rods which are oppositely arranged in parallel. Each guide rod is provided with a guide sleeve. The blade assembly comprises a blade and a blade installation base. The blade installation base is arranged between the two guide rods. The blade is arranged below the blade installation base. The broach is simple in structure and easy and convenient to operate, time and labor are saved, the labor intensity of operators is relieved, the labor cost is saved, fingers are effectively prevented from being scratched by the blade, the safety is good, the cutting efficiency is high, and fractures are neat.

Owner:临沂矿业集团菏泽煤电有限公司

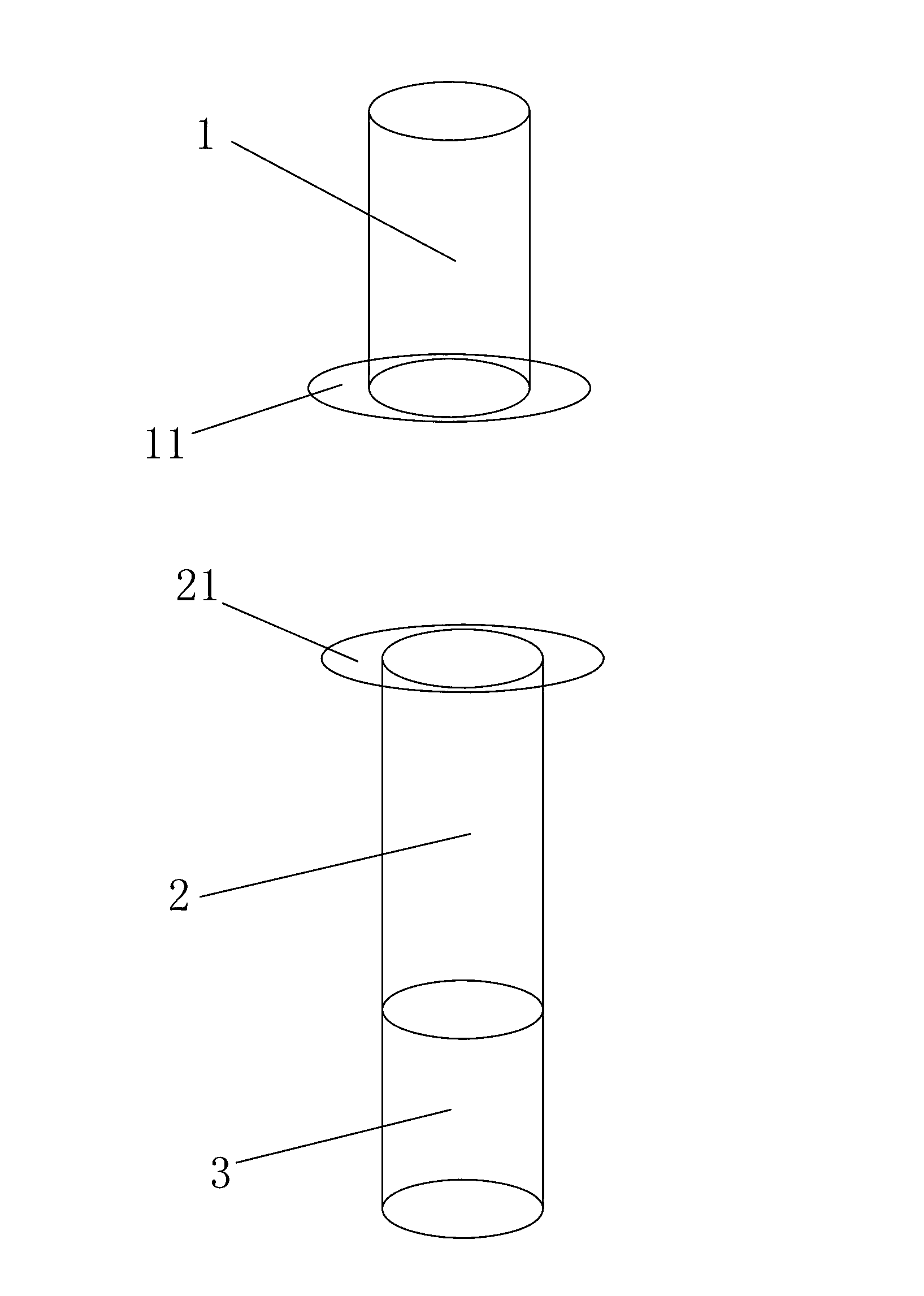

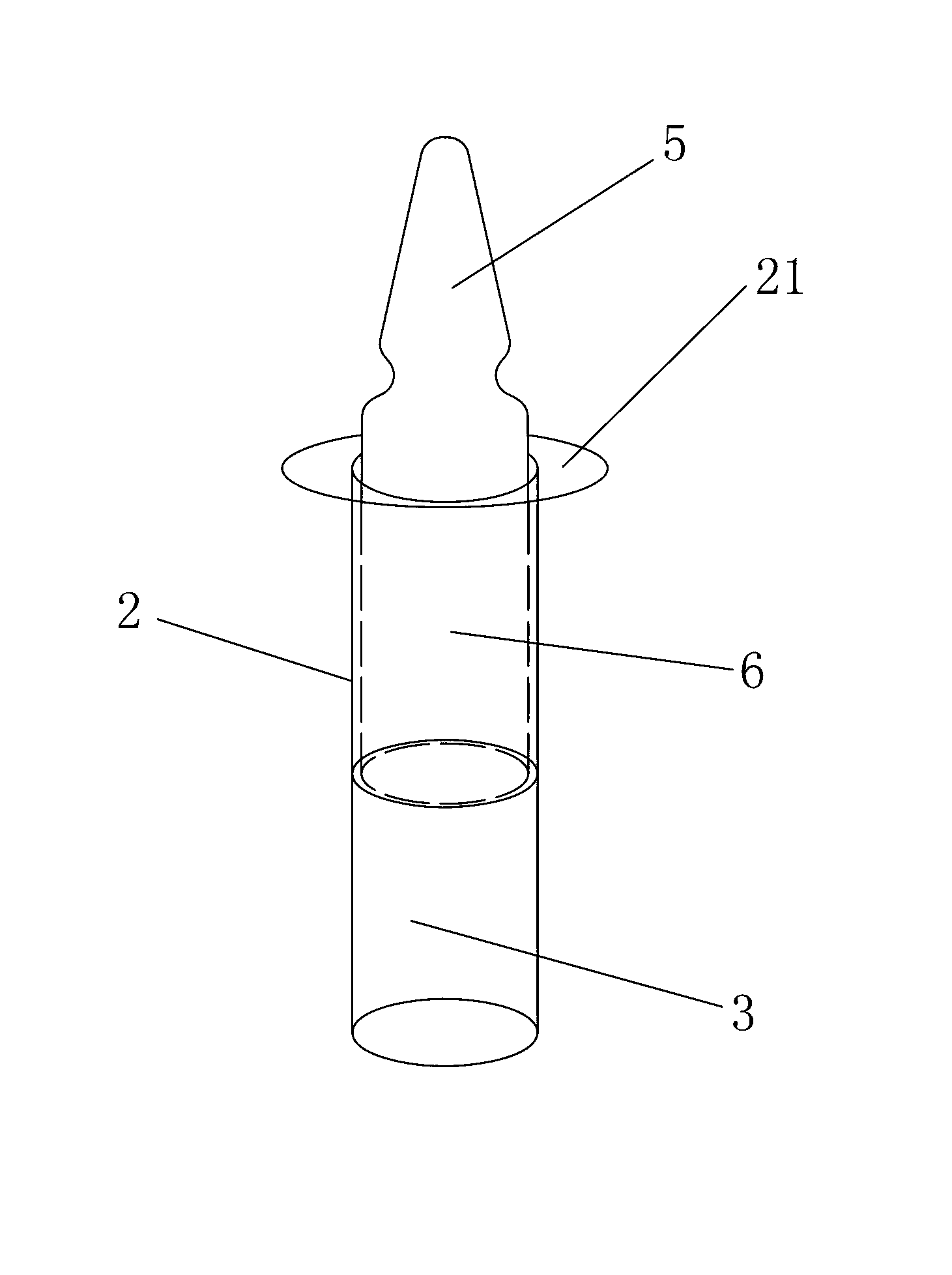

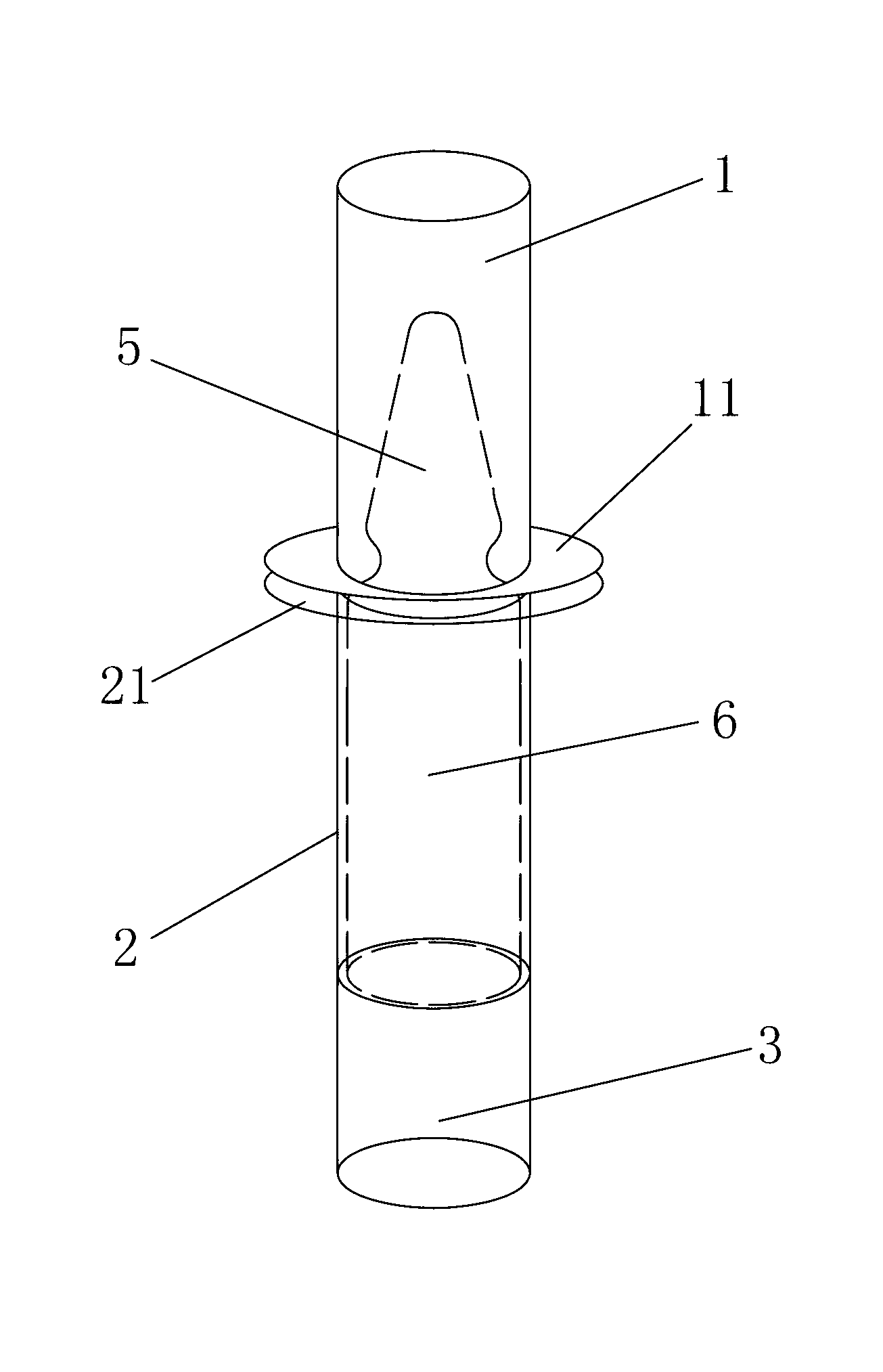

Ampule folding device with fold edges and method for folding ampule by using ampule folding device

ActiveCN102795582ASimple structureEasy to get materialsOpening closed containersBottle/container closureLongest DiameterEngineering

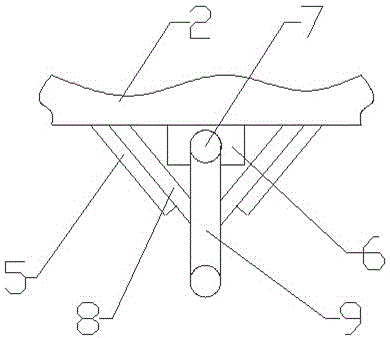

The invention discloses an ampule folding device with folding edges. The ampule folding device comprises an upper cylinder for protecting an ampule head and a lower cylinder for protecting an ampule body, wherein the lower opening end of the upper cylinder and the upper opening end of the lower cylinder are respectively provided with a fold edge extending outwards, and the inner bottom of the lower cylinder is provided with an elastic element; the fold edges are vertical to the axle of the cylinders, and the horizontal surfaces of the fold edges are elliptic; and the length of the elliptic fold edge arranged at the lower opening end of the upper cylinder in the long diameter direction is larger than that of the elliptic fold edge arranged at the upper opening end of the lower cylinder in the short diameter direction. The ampule folding device is simple in structure, convenient to obtain materials, low in cost, simple in apparatus manufacture and capable of ensuring the safety of both hands of an operator; and meanwhile, both hands of the operator cannot be in direct contact with the glass of an ampule when the ampule is folded, so that the tension of the operator in folding the ampule can be thoroughly eliminated, and requirements for folding ampules with various specifications can be met.

Owner:BEIJING HOSPITAL

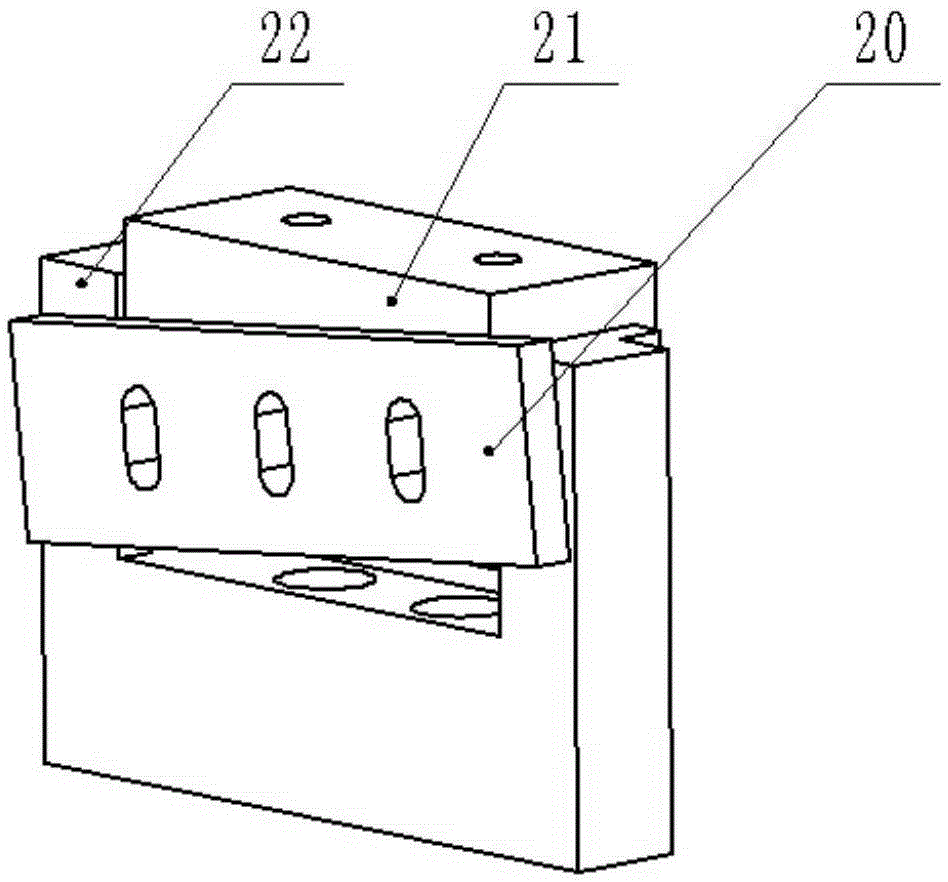

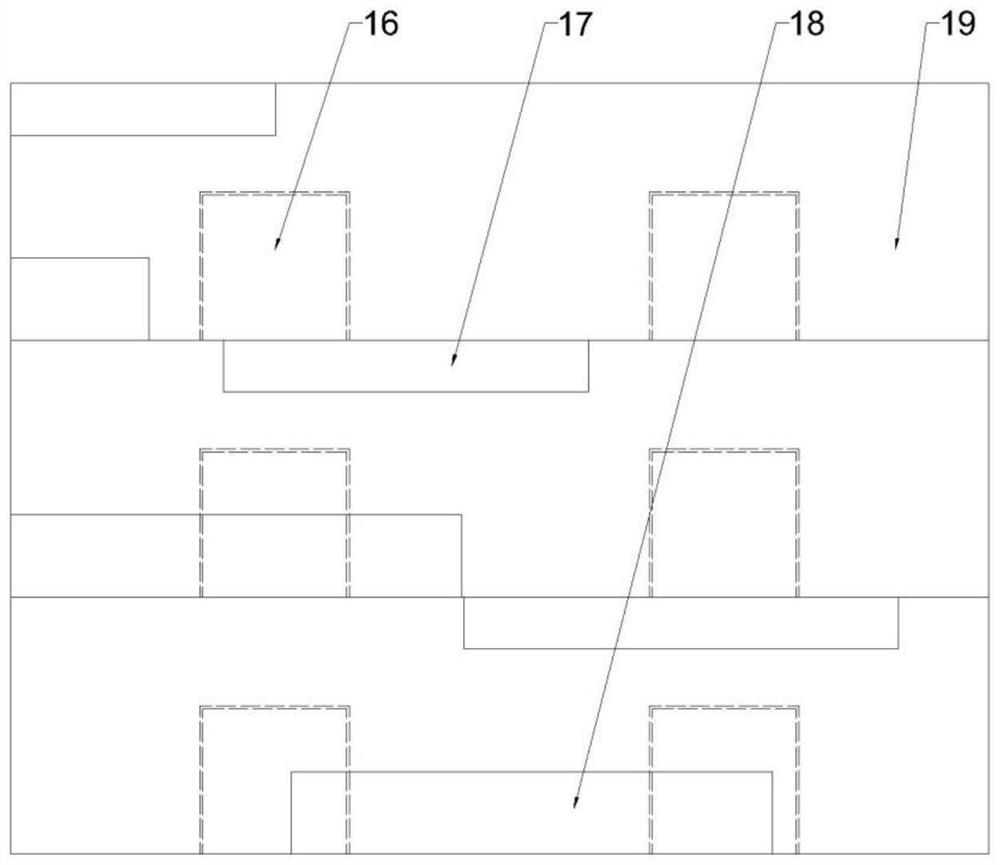

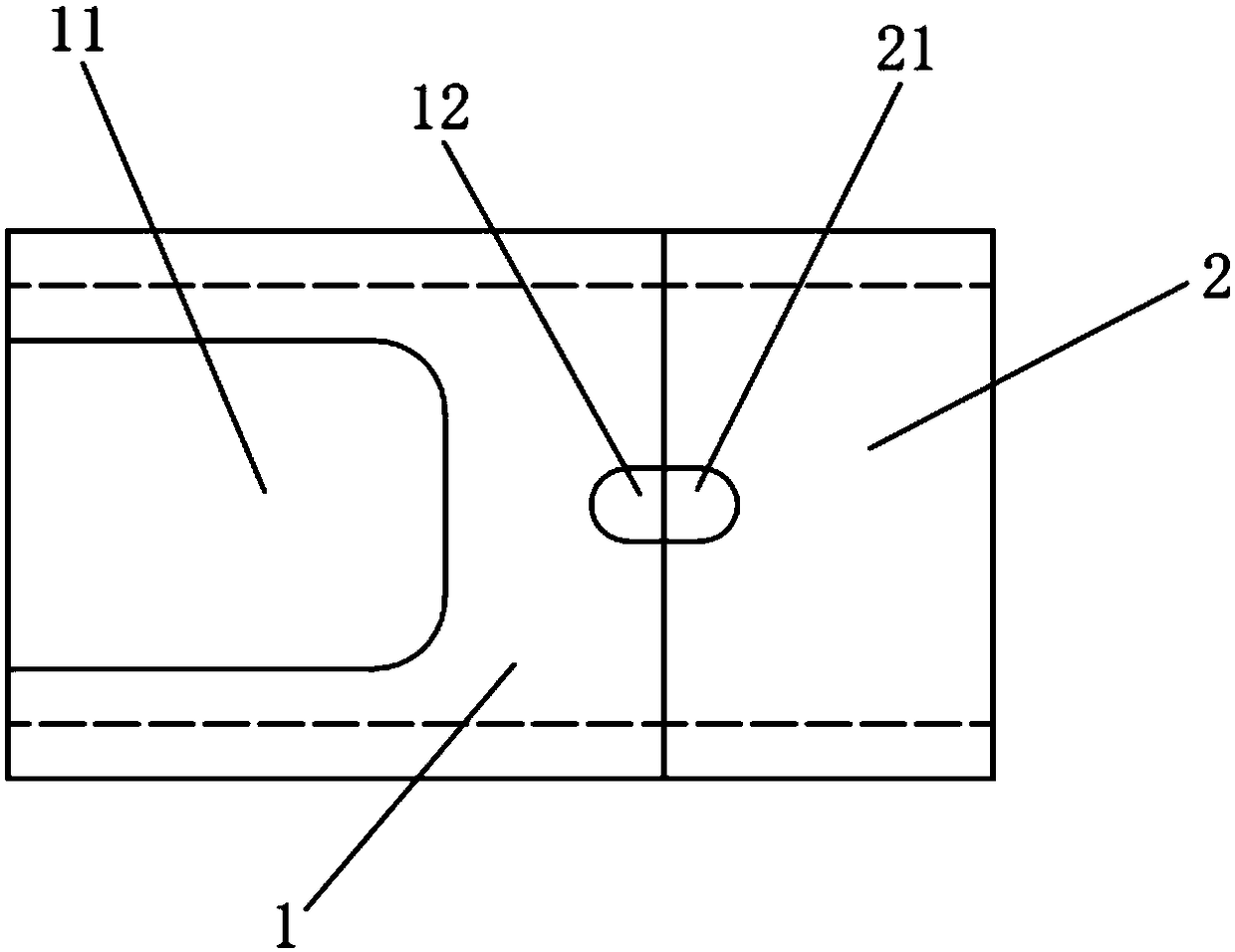

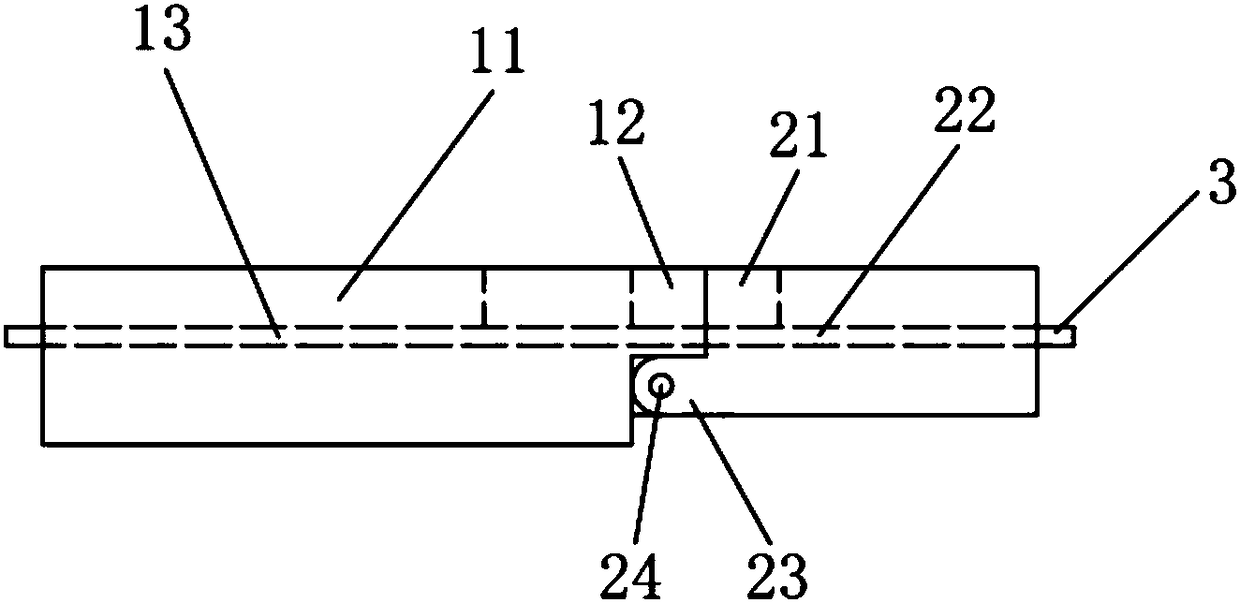

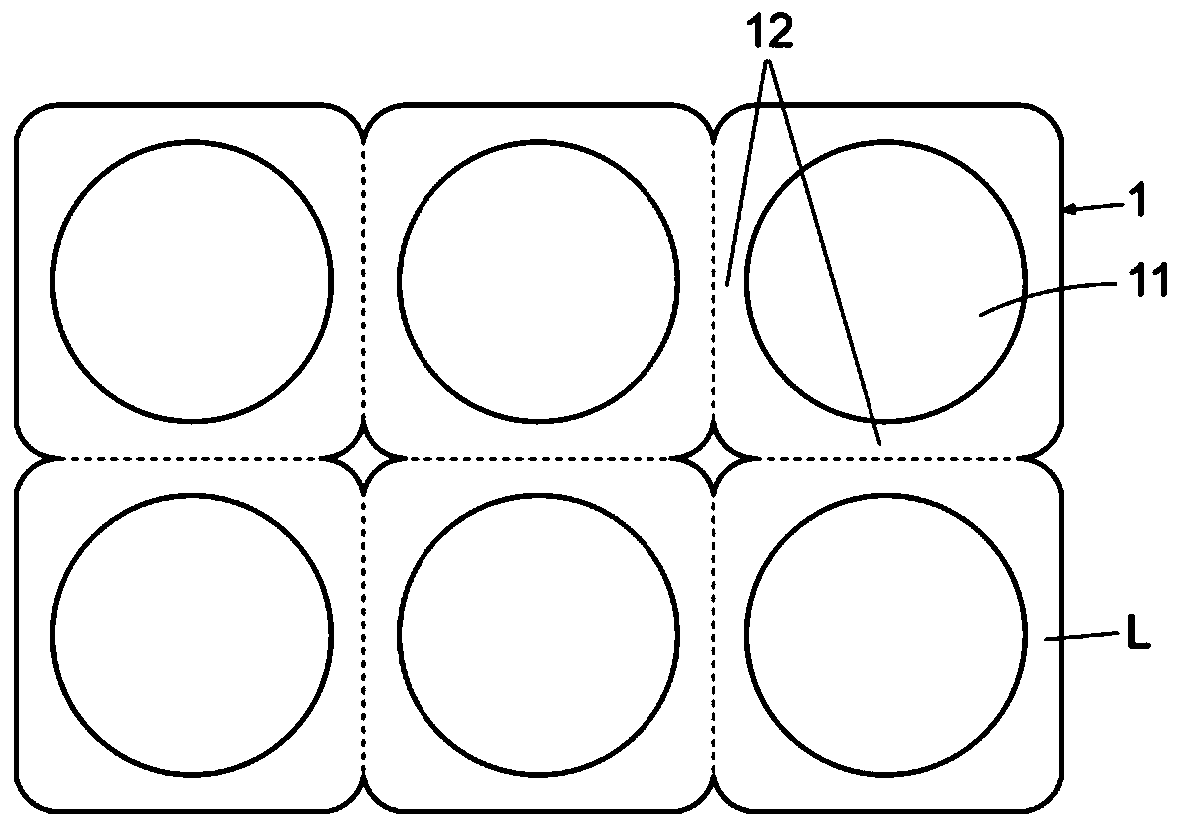

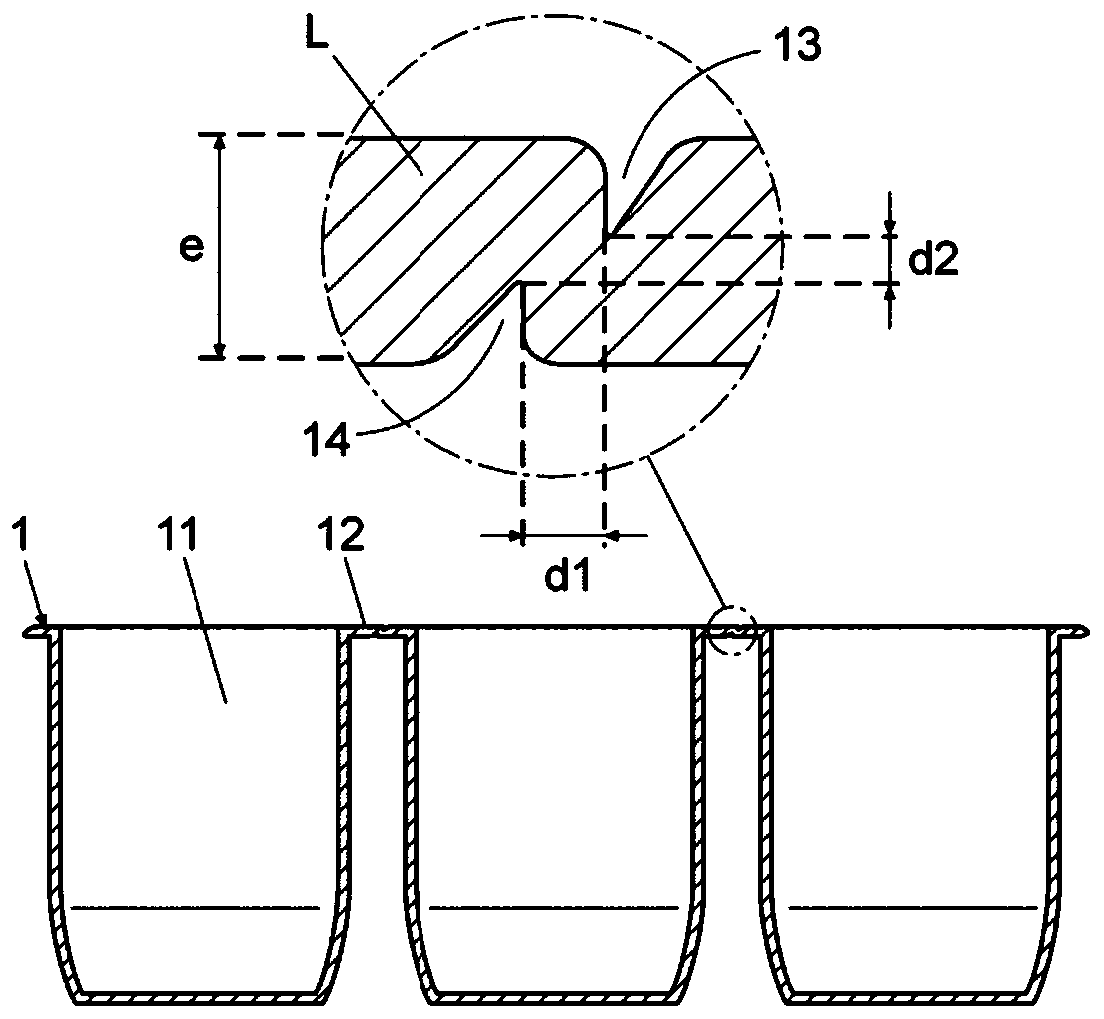

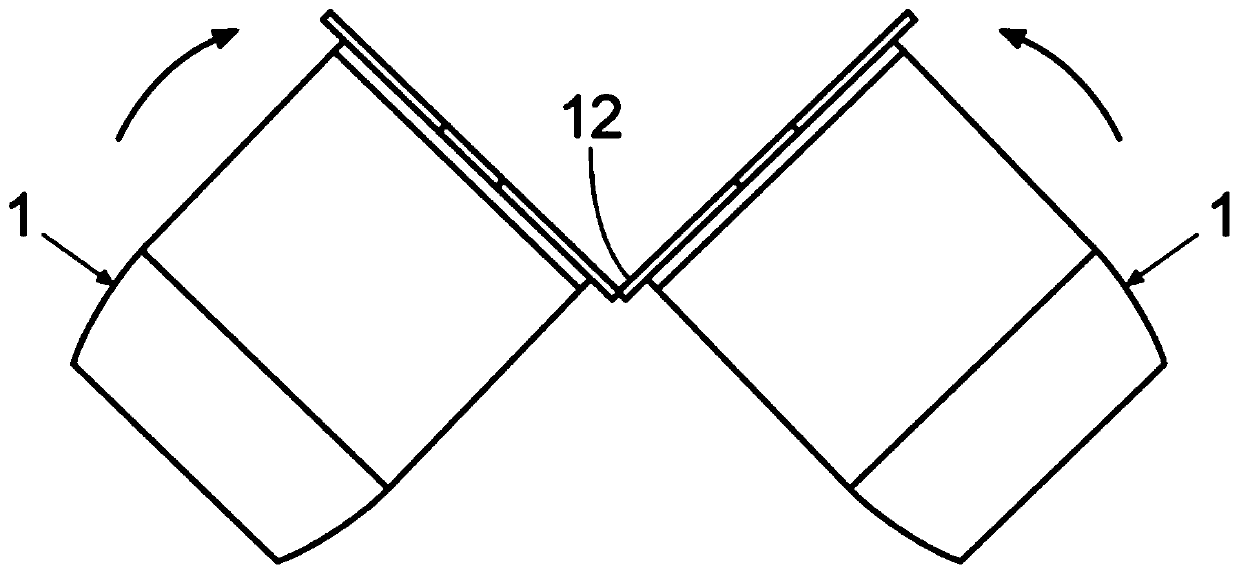

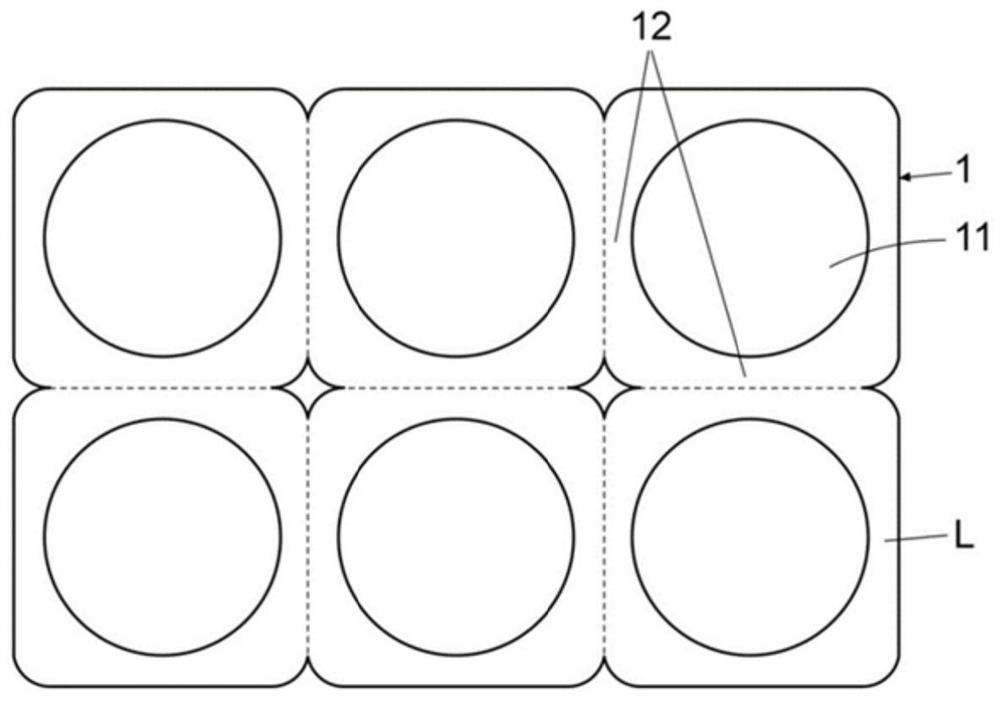

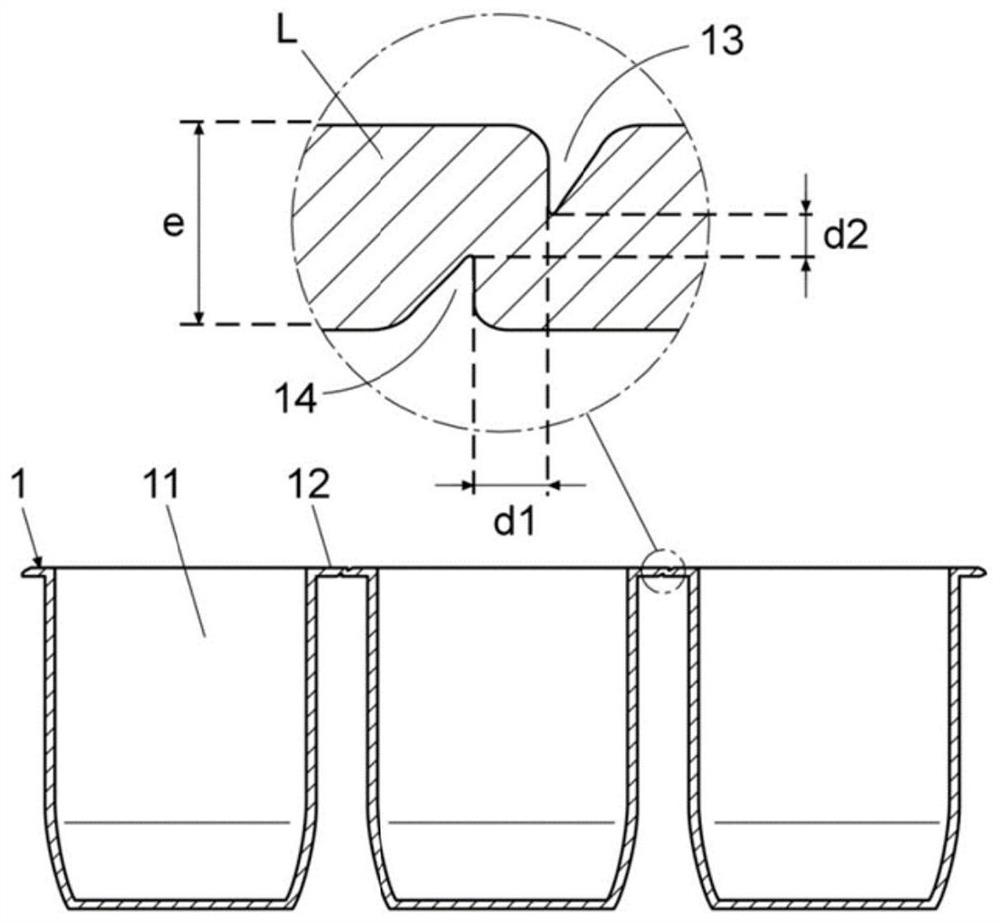

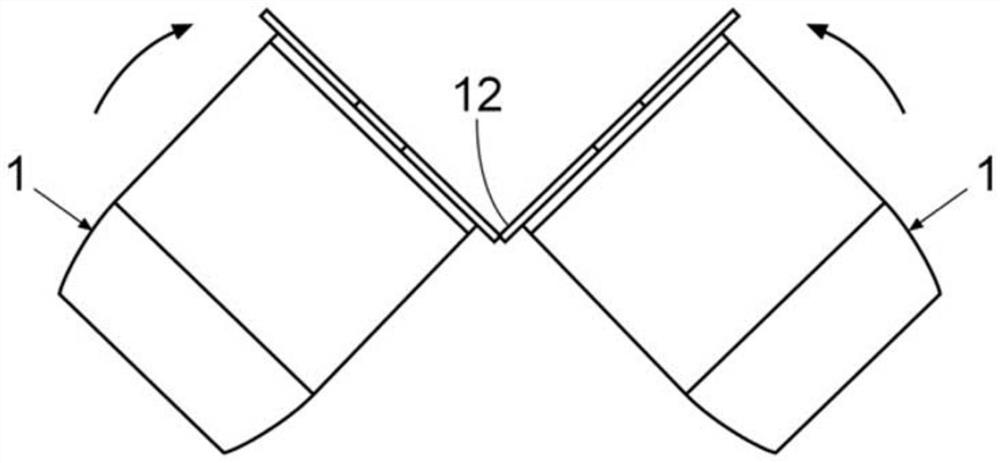

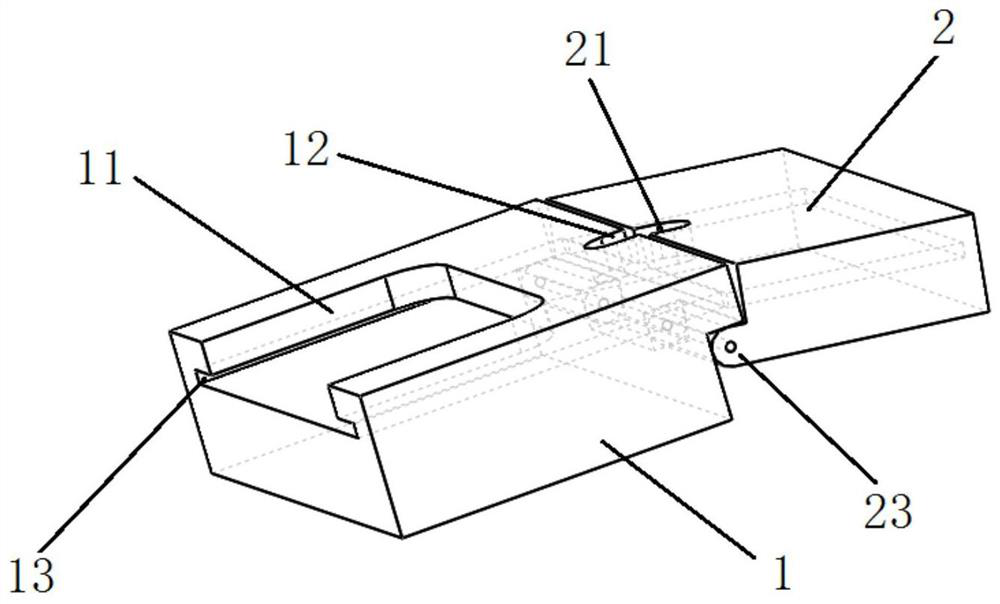

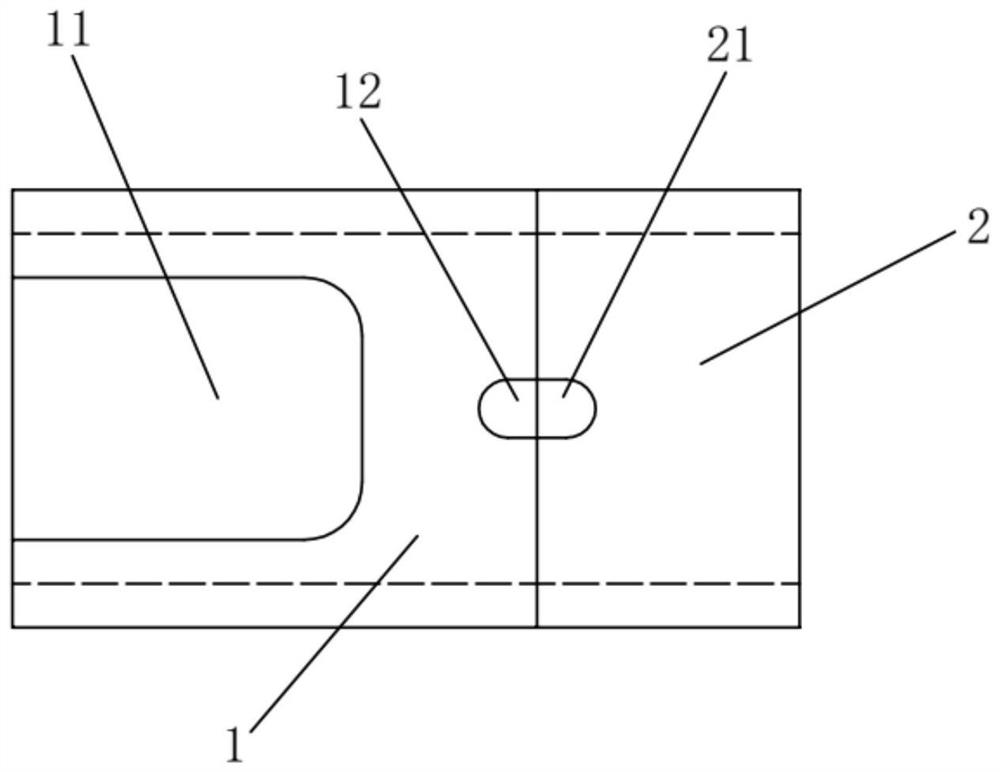

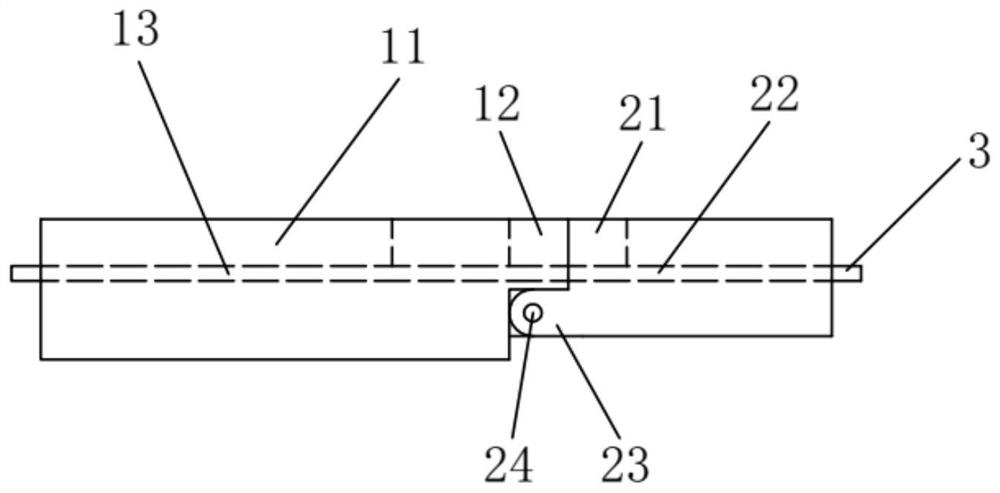

Combined containing box and manufacturing device thereof

ActiveCN111573004AChange physical propertiesNeat fractureLayered productsFilament handlingPolymer sciencePolyethylene terephthalate glycol

The invention relates to a combined containing box. The box comprises a plurality of independent containing boxes (11), each independent containing box is formed by a plastic plate (L) containing at least one PET layer (polyethylene glycol terephthalate), the independent containing boxes (11) are connected through a connecting bridge (12), and the connecting bridge is provided with an upper pre-cutting line (13) and a lower pre-cutting line (14) which are used for disconnecting the connecting bridge. The upper pre-cutting line (13) and the lower pre-cutting line (14) are parallel in the horizontal direction, are transversely spaced and are mutually spaced in the vertical direction, so that the situation that the characteristics of the PET layer are changed when the compression heat is toohigh is avoided, and meanwhile, the connecting bridge can be tidily disconnected by rotating the containing box at the positions of the upper pre-cutting line and the lower pre-cutting line. The invention further provides a device for manufacturing the combined containing box.

Owner:机械自动化工业技术股份有限公司

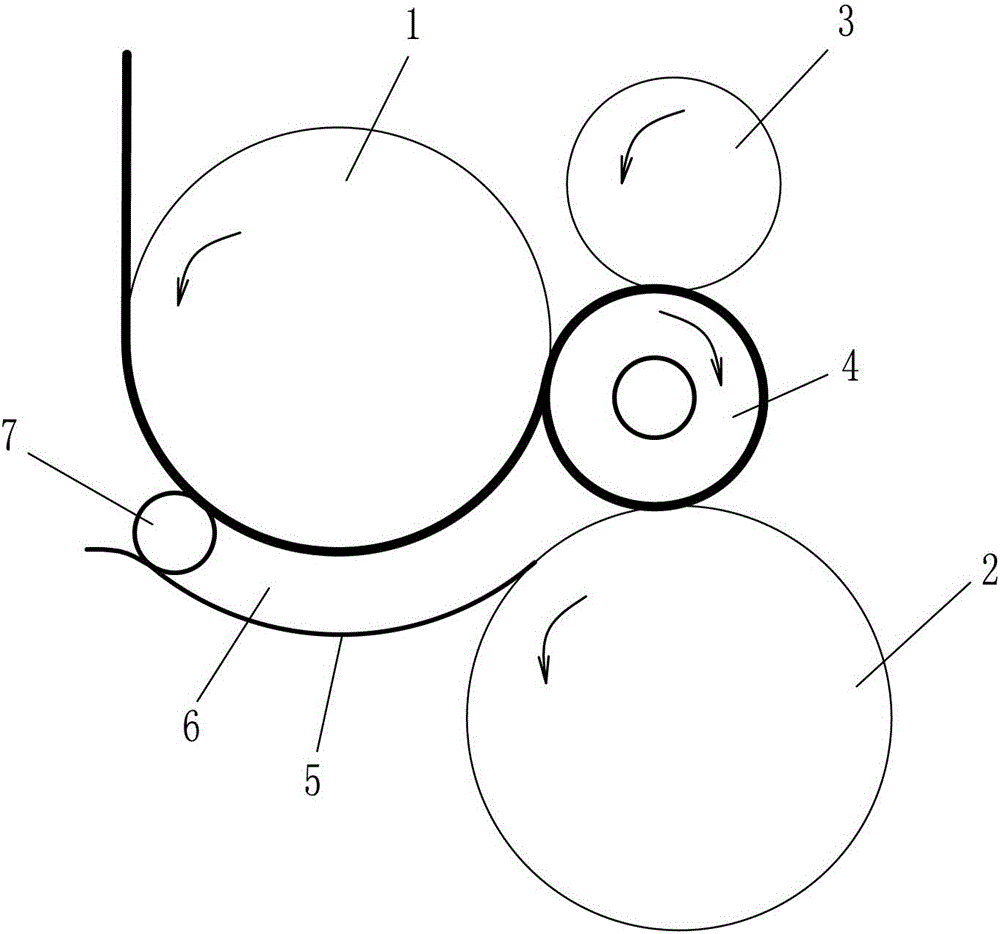

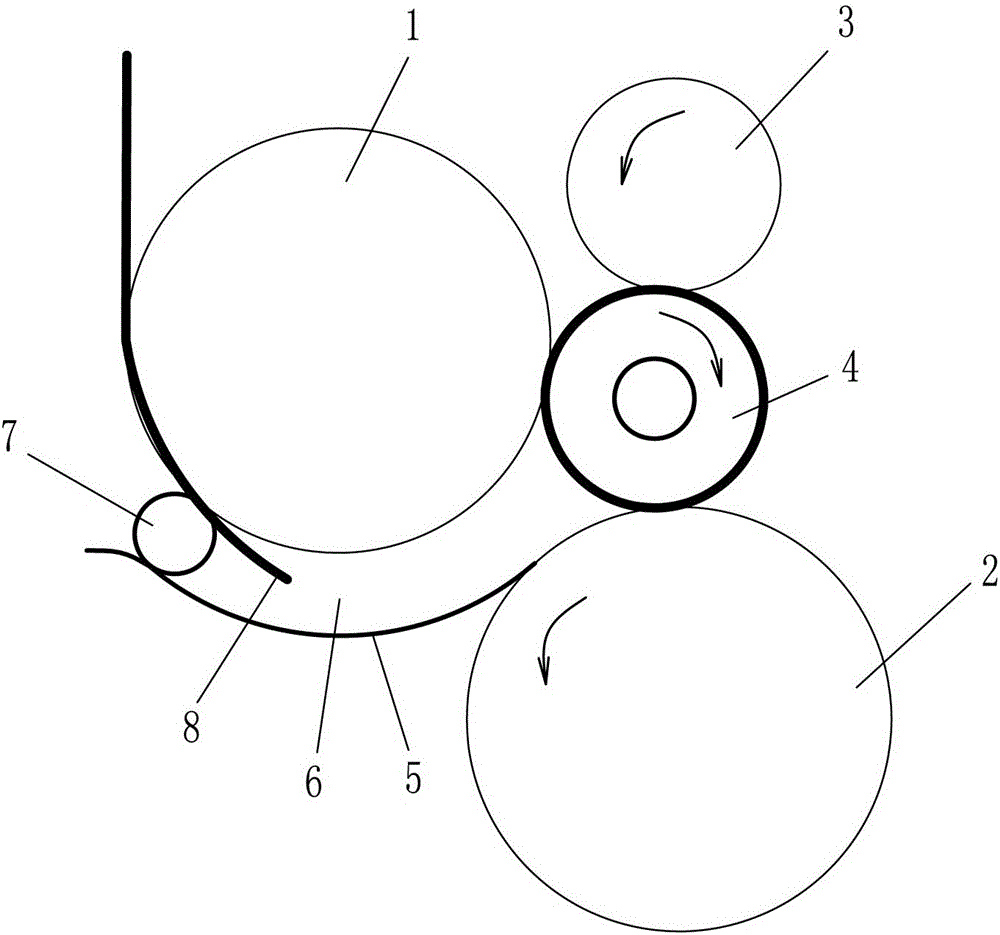

A kind of rewinding machine and paper breaking and winding method of the rewinding machine

The invention discloses a paper breaking and rewinding method for a rewinder. Its main feature is that when the core tube is just pressed against the rewinding upper roll, the rewinding upper roll is prevented from driving the core tube to roll, so that the paper The paper at the end of the roll is stretched and broken. After the paper is broken, the barrier is removed, so that the paper head formed after the paper is broken is wound on the rolling core tube to form a new paper roll. The invention also discloses a rewinder capable of realizing the above method. The rewinder is provided with a core tube damping mechanism at the entrance of the core tube channel. The advantage of the present invention is that only after the paper at the tail of the paper roll is broken, the core tube pressed against the rewinding upper roller can roll along the core tube channel, thereby ensuring that the paper at the tail of the paper roll can be reliably broken, and at the same time It avoids the uneven stress on the paper at the end of the paper roll caused by the rolling of the core tube, and the paper breaks are neat.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

Steel pipe cutting equipment with automatic clamping function

InactiveCN112643119AEasy clampingNeat fractureTube shearing machinesShearing machine accessoriesElectric machineryScrew thread

The invention discloses steel pipe cutting equipment with automatic clamping function. The equipment comprises a base, a cutting table is arranged on the left side of the base, a first motor is installed in the cutting table, the first motor is connected with a threaded rod, the threaded rod is connected with a bearing on the inner wall of the cutting table, the threaded rod is rotationally connected with a fixing block, the threaded rod is in threaded connection with the lower end of a knife rest, a cutting knife is installed on the knife rest, the knife rest is arranged in a sliding groove, the sliding groove is formed in the cutting table, an installation table is arranged in the middle of the base and connected with a rotary disc bearing, a limiting disc is arranged on the right side of the rotary disc, a limiting groove is formed in the limiting disc, and a rotating disc is arranged between the rotating disc and the limiting disc. The steel pipe cutting equipment with automatic clamping function can conveniently clamp a steel pipe when the steel pipe is sectioned, so that steel pipe cutting equipment with automatic clamping function can conveniently guarantee that the fracture of the sectioned steel pipe is neat, and the steel pipe with fixed length can be conveniently and automatically conveyed to a cutting position to be cut.

Owner:芜湖博威机械制造有限公司

Device and method for cutting spent fuel rods

The invention discloses a spent fuel rod cutting device and method. The spent fuel rod cutting device comprises a pipe cutter, a flow guiding cover, a pipe sleeve, a filter, a low-pressure blower and an ejector rod. Two holes are formed in the side wall of the flow guiding cover. The pipe cutter is arranged in the flow guiding cover. The flow guiding cover is connected with the pipe sleeve. The ejector rod and the flow guiding cover holes are on the same horizontal line. The filter is arranged between the flow guiding cover and the low-pressure blower. The spent fuel rod cutting method comprises the following steps that (1) all the components are connected, and the position height is adjusted; (2) the pipe cutter and a spent fuel rod are arranged in suitable positions; (3) cutting is conducted; and (4) a cutting port is sleeved with a protective sleeve. According to the spent fuel rod cutting device and method provided by the invention, remote operation can be conducted, the structure is simple, the occupied space is small, the reliability is high, cutting environment radioactive substance pollution diffusion can be effectively controlled, and the hot chamber operation cost is reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

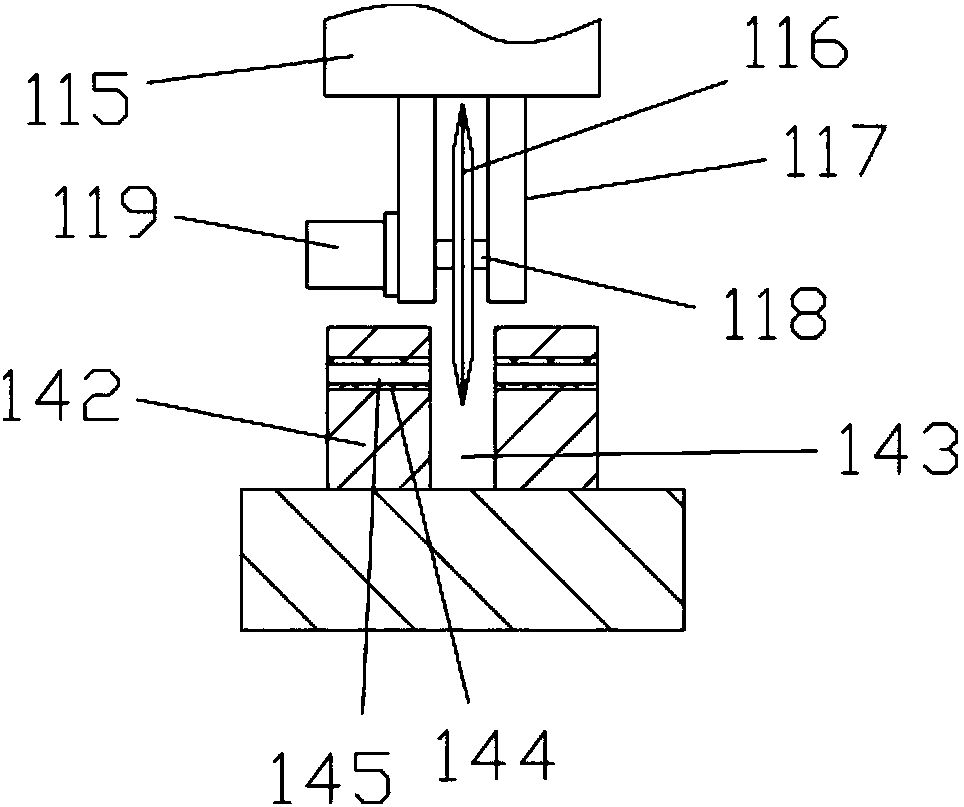

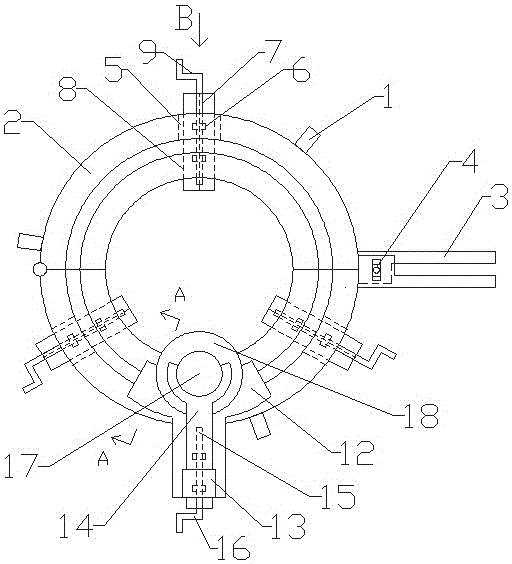

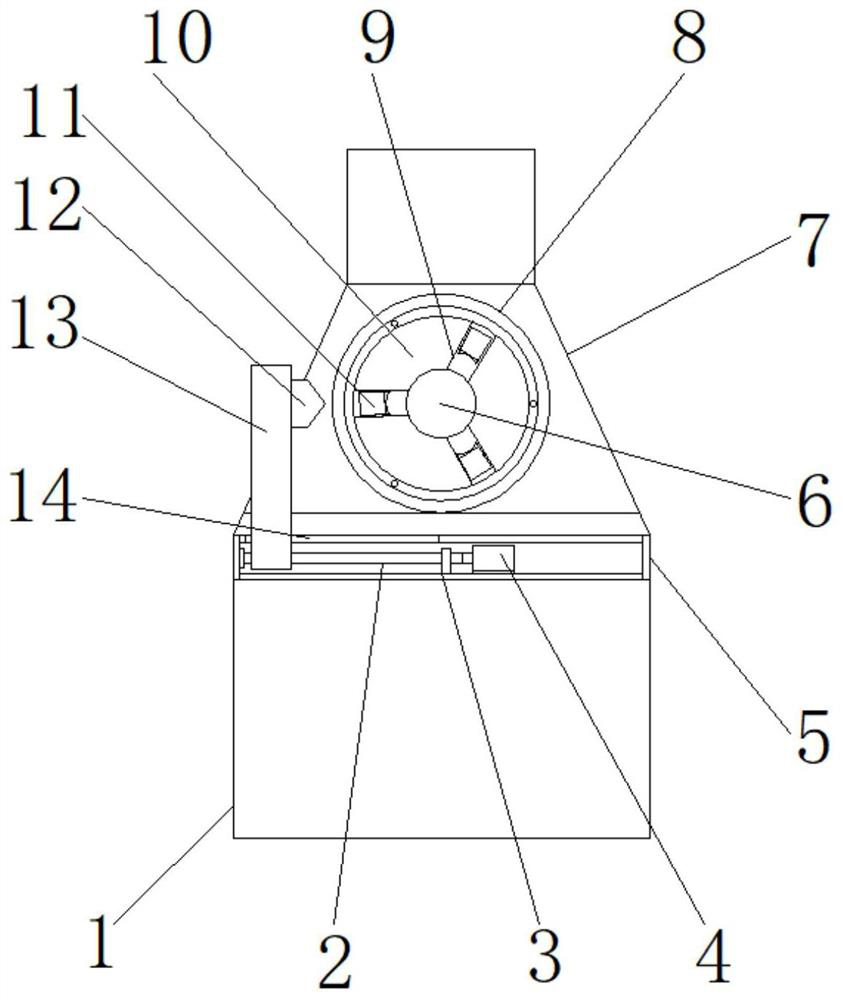

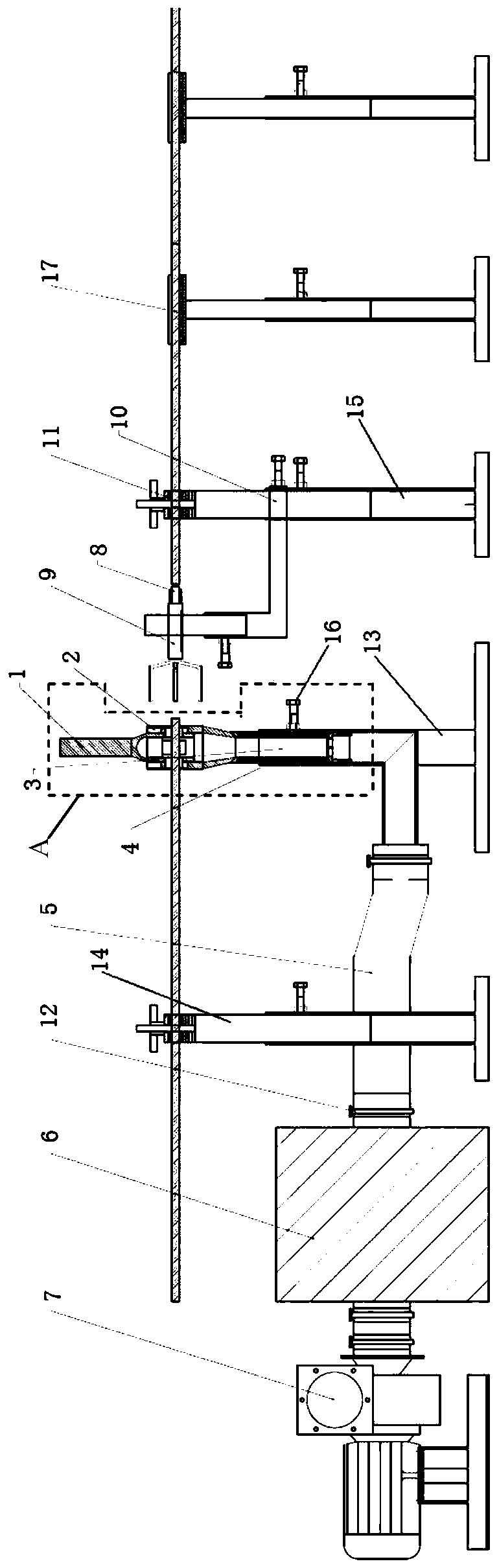

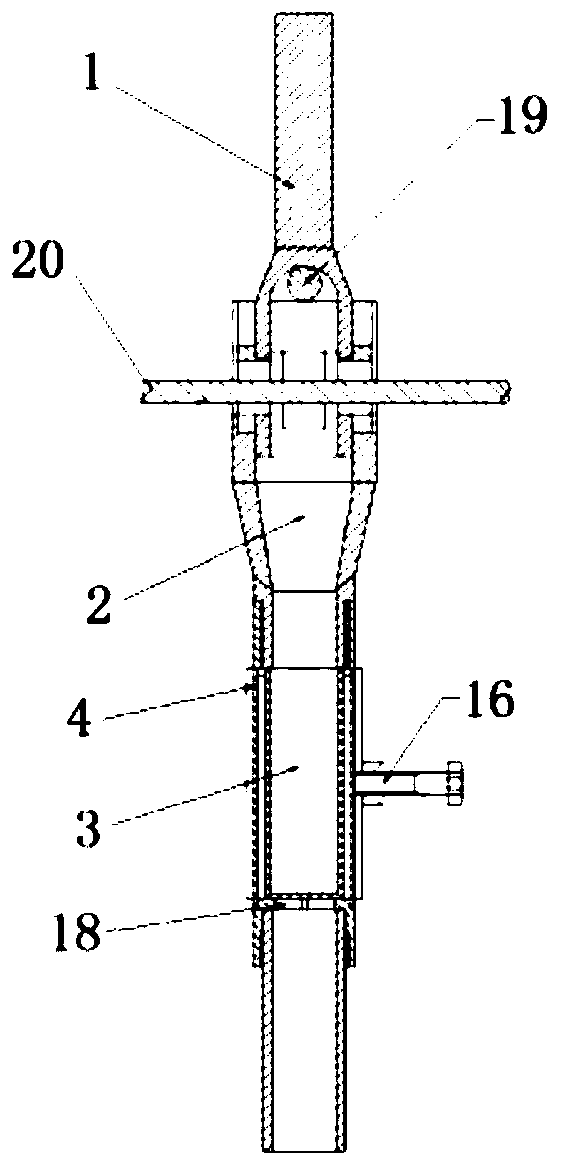

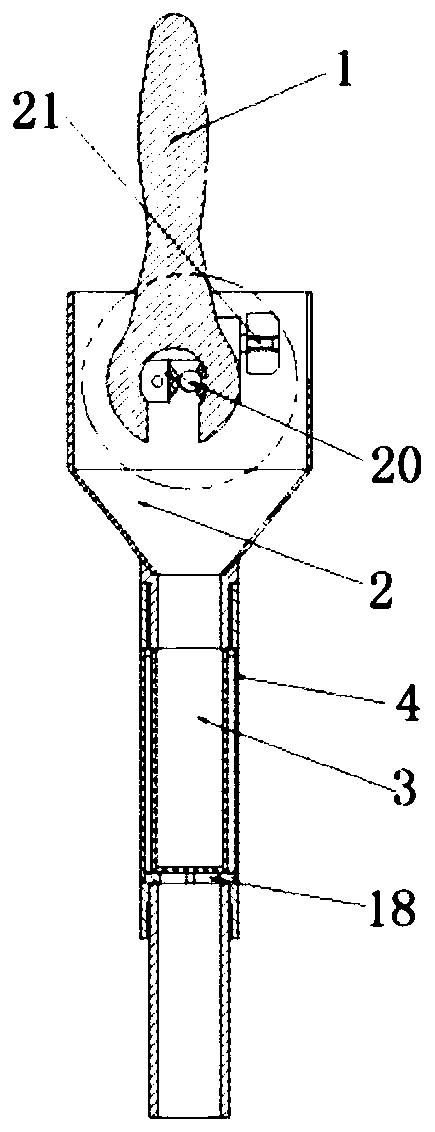

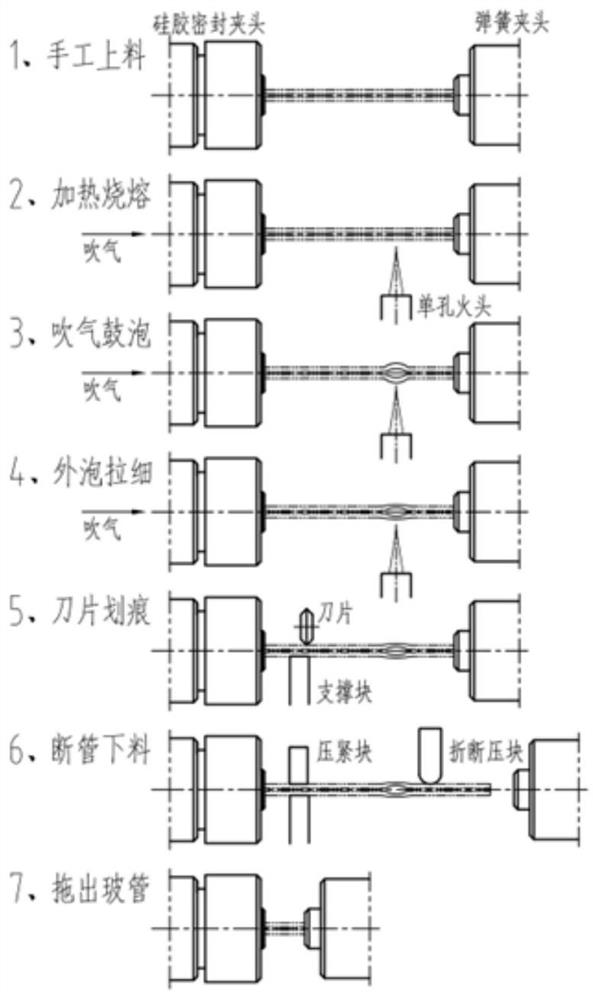

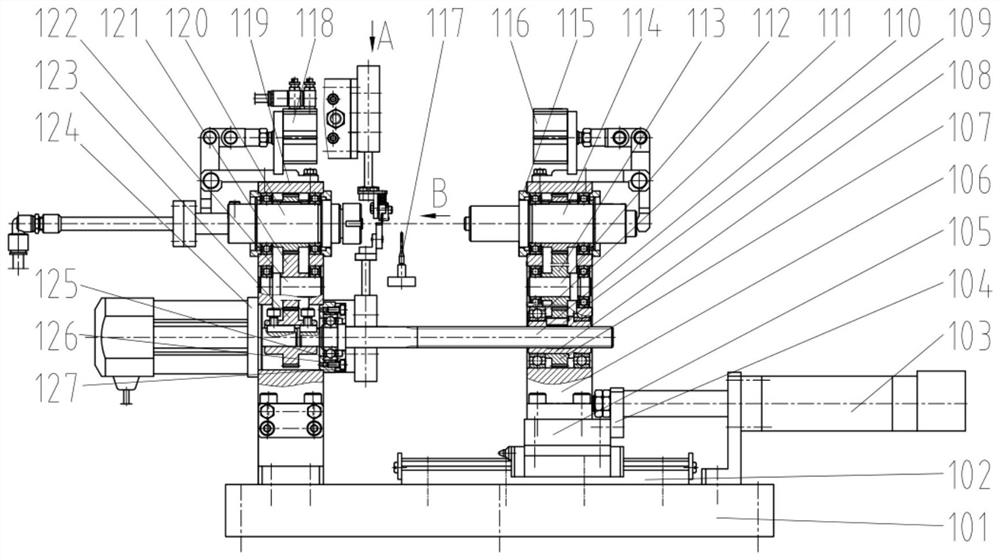

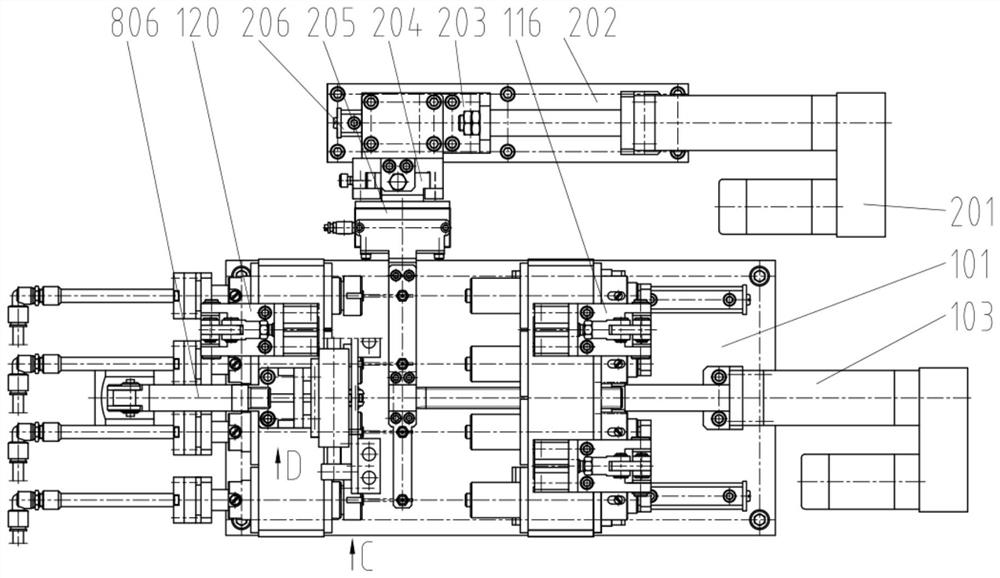

Method and equipment for bubble blowing and tube breaking in glass capillary tube

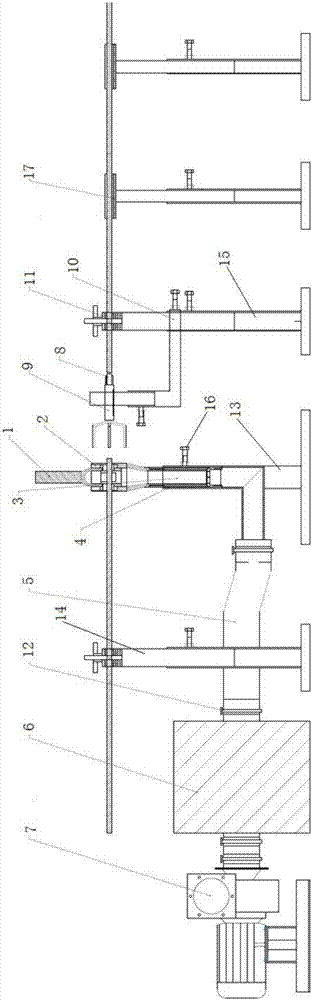

ActiveCN113024100AGood size consistencyNeat fractureGlass reforming apparatusGlass severing apparatusCapillary TubingEngineering

The invention discloses a method and equipment for bubble blowing and tube breaking in a glass capillary tube. The equipment comprises a left end chuck assembly, a right end chuck assembly, a right end chuck body moving mechanism, a fire head assembly, a fire head moving mechanism, a capillary tube supporting block mechanism, a capillary tube scratching mechanism, a capillary tube breaking mechanism and a synchronous rotating mechanism capable of promoting the left end chuck assembly and the right end chuck assembly to rotate synchronously. The left end chuck assembly is used for clamping the capillary tube through contraction of sealing colloidal particles, and a rotating joint is arranged at the tail part of the left end chuck assembly so as to carry out air inlet bubbling on the clamped capillary tube. The right end chuck assembly clamps the capillary tube in the mode that an inner hole is contracted through a spring chuck. The capillary tube scratching mechanism comprises a capillary tube supporting block, a scratching driving mechanism and a capillary tube scratching blade connected with the transmission end of the scratching driving mechanism. According to the invention, automatic bubble blowing and pipe breaking processing can be realized, multiple groups can be arranged side by side for simultaneous processing, the production efficiency is improved, the labor intensity of workers is reduced, and the quality consistency is good.

Owner:SOUTHEAST UNIV

Reliable and tidy rewinder for web breaks

The invention relates to a re-reeling machine capable of reliably and tidily cutting paper. The re-reeling machine comprises an upper re-reeling roller, a bottom re-reeling roller and a paper-pressing roller, which all rotate by clamping a paper scroll, wherein a cylindrical surface of the upper re-reeling roller and a fixed curved surface are close to each other, so as to form a core tube channel, and the cylindrical surface of the upper re-reeling roller is provided with a plurality of circles of smooth surfaces which are slightly protruded from a friction surface of a roller body. The re-reeling machine capable of reliably and tidily cutting paper has the advantages that a core tube cannot be immediately driven to roll by the upper re-reeling roller when the upper re-reeling roller is just pressed by the core tube, so that the paper sheet at the tail of the paper scroll can be reliably broken, the uneven stress on the paper sheet at the tail of the paper scroll caused by the rolling of the core tube is avoided, the fractures of the paper sheet are tidily, and furthermore, when the upper re-reeling roller, the bottom re-reeling roller and the paper-pressing roller all rotate by clamping the paper scroll, the friction surface of the upper re-reeling roller still can be in sufficient contact with the surface of the paper scroll and is not influenced by the smooth surfaces, so that the upper re-reeling roller can reliably rotate at high speed by clamping the paper scroll together with the bottom re-reeling roller and the paper-pressing roller.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

A combined storage box and its manufacturing device

ActiveCN111573004BNeat fractureLayered productsFilament handlingPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to a combined container comprising a plurality of individual containers (11), each of which is formed from a plastic sheet (L) comprising at least one layer of PET (polyethylene terephthalate) Each independent storage box (11) is connected by a connecting bridge (12), and an upper pre-cutting line (13) and a lower pre-cutting line (14) for disconnecting the connecting bridge are arranged on the connecting bridge. The upper pre-cutting line (13) and the lower pre-cutting line (14) are horizontally parallel and spaced laterally, and are spaced from each other in the vertical direction, so as to avoid changes in the properties of the PET layer when the heat of compression is too high. Rotating the holding box at the upper and lower pre-cut lines can neatly disconnect the connecting bridge. The invention also provides a device for manufacturing the combined storage box.

Owner:机械自动化工业技术股份有限公司

A conductive glass edge breaker

InactiveCN108503208BDon't worry about damageAvoid damageGlass severing apparatusMechanical engineeringElectrical and Electronics engineering

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Sheet Metal Cutting Machine

ActiveCN105328255BAvoid Knife Collision SituationsIncrease cut-off pressureShearing machinesShearing machine accessoriesMetal stripsDrive shaft

The invention discloses a metal sheet cutting machine, which includes an automatic feeding part and a cutting part. The automatic feeding part is driven by a servo motor through a synchronous wheel and a synchronous belt to drive the feeding rubber roller and the pressing roller to rotate precisely according to the feeding length; The metal flakes in the middle are accurately conveyed forward under the guidance of the feeding guide assembly to complete the automatic feeding function of the cutting machine. The cutting parts are powered by the motor, and after being driven by the synchronous wheel and synchronous belt, the eccentric wheel on the transmission shaft is driven to rotate, and the eccentric The movement acts on the frame body through the bearing transmission, and at the same time, under the guidance of the guide assembly, it finally drives the cutter to move up and down in a straight line, thereby cutting off the metal sheet. The invention can automatically feed and cut a plurality of thin metal strips at the same time, has high working efficiency, easy installation of knives, high length precision after cutting, and neat fractures.

Owner:NANJING INST OF TECH

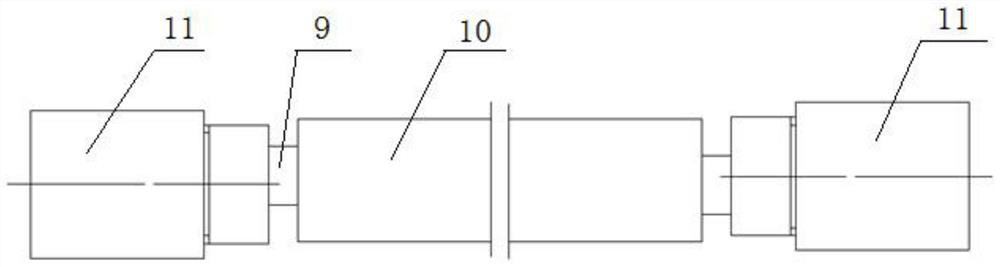

Cable mandrel cutting machine

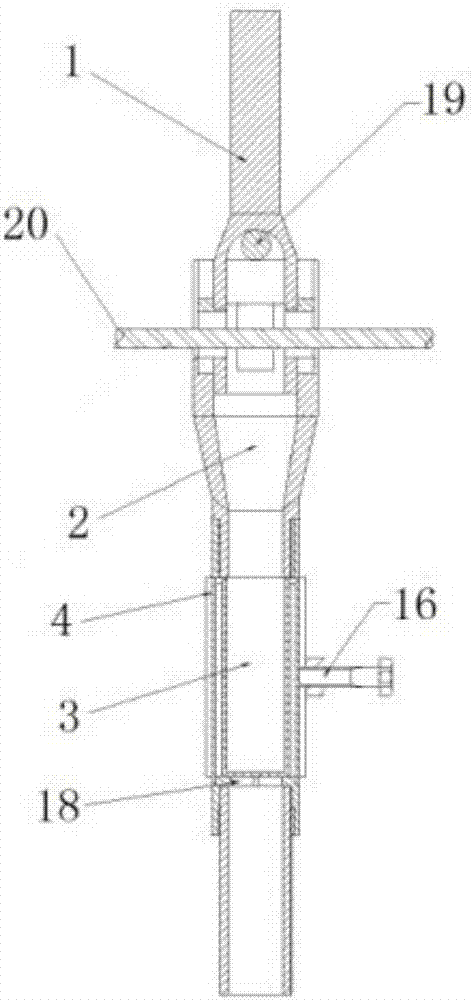

ActiveCN102814582BImprove cutting effectNeat fractureResistance welding apparatusPower flowControl system

The invention provides a cable mandrel cutting machine, belonging to the field of cutting and aiming to solve the problem of inaccurate cutting precision of the existing cable mandrel. The cable mandrel cutting machine comprises a stand, a conveying structure, a control system and a cutting structure; the cutting structure comprises electrodes, a first air cylinder, a second air cylinder, a first crowbar and a second crowbar; the first air cylinder and the second air cylinder are arranged on two sides of the electrodes; the electrodes comprise an upper electrode and a lower electrode; and the lower electrode is fixedly connected on the stand. Due to the arrangement of the cutting structure of the cable mandrel cutting machine, the cable mandrel can be cut by fusing by the instantaneous high current, good cable mandrel cutting effect can be achieved, and the fracture of the cable mandrel is neat without burrs. The cable mandrel cutting machine is convenient to use and has high precision.

Owner:NINGBO GAOFA AUTOMOTIVE CONTROL SYSTEM CO LTD

Rapid sawing machine

The invention discloses a rapid sawing machine comprising a frame, blades, a rotary arm, motors, static cutters and a protective cover. The rotary arm is arranged on the frame and connected with the motors in the centers thereof. The blades are arranged at two ends of the rotary arm. The static cutters are arranged on the frame. The protective cover is around the frame. According to the arrangement, the rapid sawing machine has the advantages of high reliability, compact structure, rapid cutting, uniform fracture, capability of continuously cutting, convenience in expanding station, low cost and the like and is suitable to rapid cutting of bar-shaped materials.

Owner:SUZHOU SHUNGE INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com