Metal sheet cutting off machine

A metal sheet and cutting machine technology, which is applied to metal processing equipment, shearing devices, accessories of shearing machines, etc., can solve the problems of inability to cut metal sheets, inapplicability, etc., to increase cutting pressure and ensure linear guidance accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

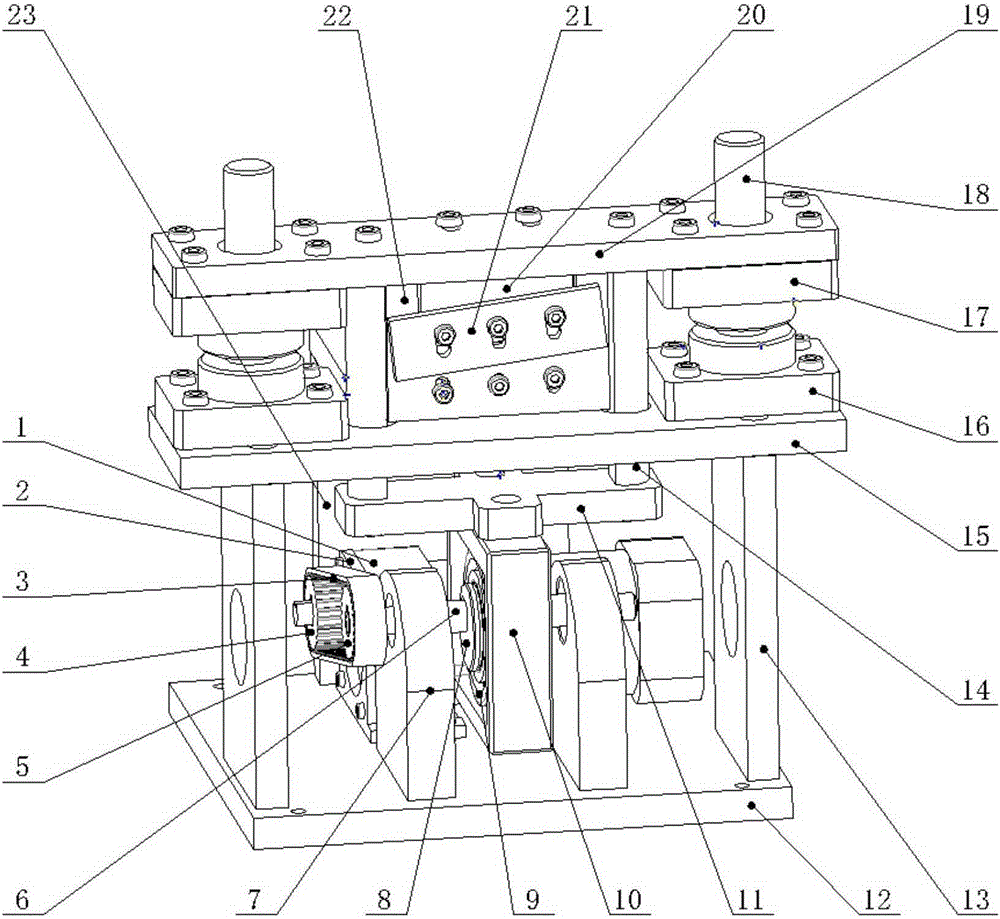

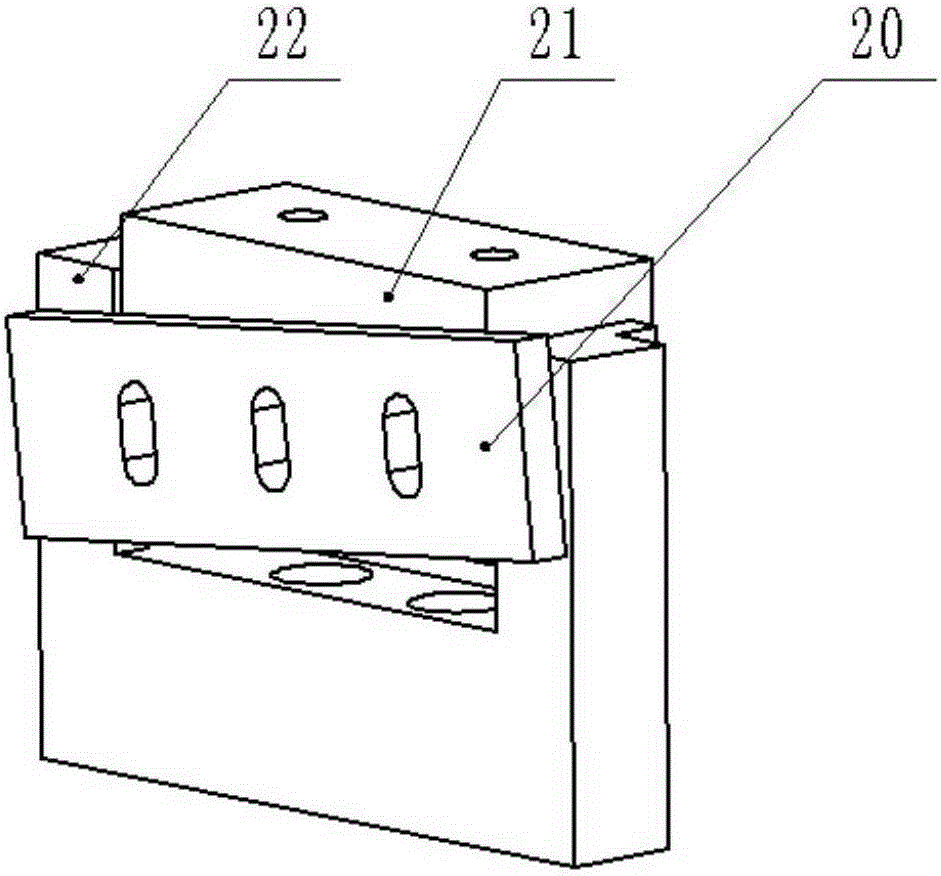

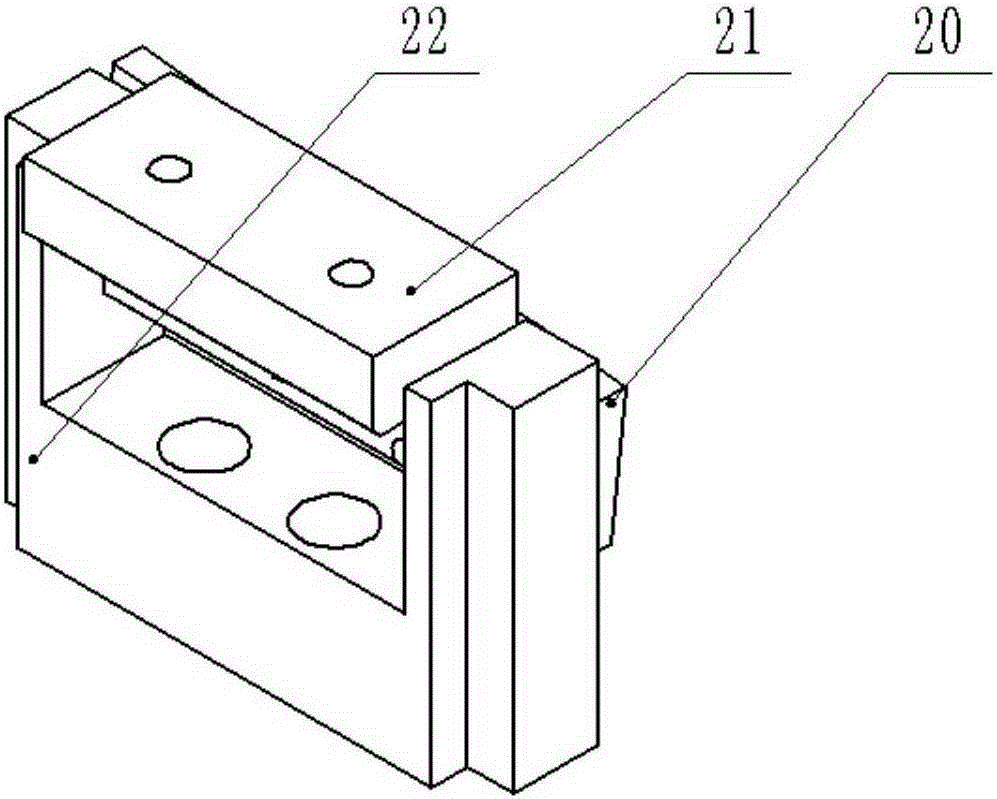

[0028] Such as Figure 1 to Figure 4 As shown, a sheet metal cutting machine can be divided into two parts in terms of structure and function, including automatic feeding parts and cutting parts;

[0029] Such as figure 1 As shown, the cutting parts of the sheet metal cutting machine mainly include cutting power transmission components, cutting guide parts and cutting execution components,

[0030]The cut-off power transmission group includes a motor 1, a motor frame 2, an arc-toothed synchronous belt 3, an arc-toothed synchronous wheel on the motor side 4, an arc-toothed synchronous wheel on the transmission shaft side 5, a transmission shaft 6, a transmission shaft bracket 7, an eccentric Disc 8, deep groove ball bearing 9, frame body 10, cross connecting plate 11, bottom plate 12, vertical plate 13, ejector rod 14. The motor 1 is fixed on the motor frame 2, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com