Spent fuel rod cutting device and method

A technology of cutting device and cutting method, which is applied in the field of reactor engineering, and can solve the problems of increased dose rate in hot chamber cutting environment, difficult manipulator operation, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in combination with the accompanying drawings and specific embodiments.

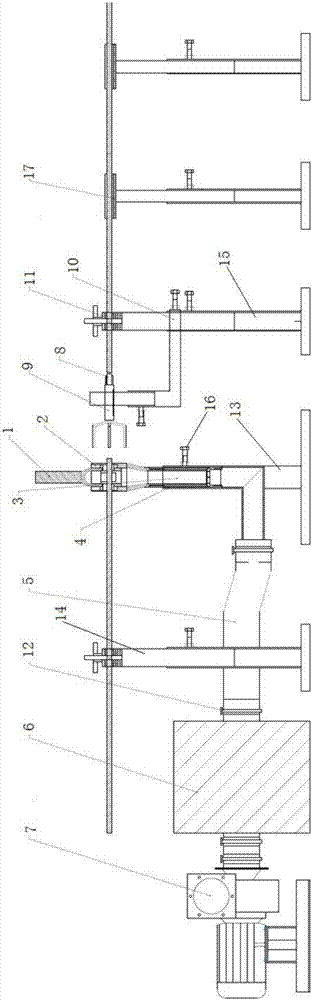

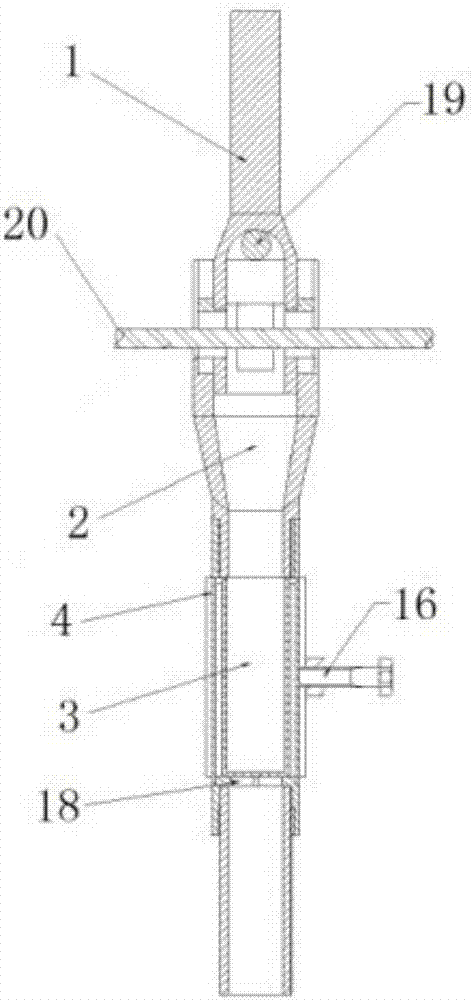

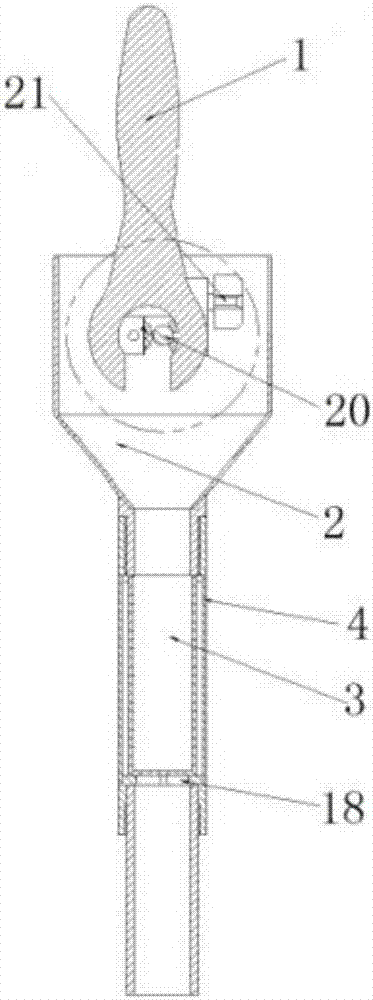

[0028] A spent fuel rod cutting device, the structure of which is as follows figure 1 As shown, the main body includes a pipe cutter 1, a shroud 2, a pipe sleeve 4, a filter, a low-pressure blower 7, a push rod 9 and a protective sleeve 8; figure 2 and image 3 As shown, the pipe cutter 1 is placed in the shroud 2, the pipe cutter 1 is a ratchet cutting tool, the positioning tube 19 is located above the shroud 2, and can be inserted into the hole of the pipe cutter 1 to fix the pipe cutter 1; the deflector 2 is a transparent radiation-resistant polymer material, the upper opening is a cavity structure, in the shape of a funnel, and the lower end is connected to the sleeve 4 through threads; two holes are provided at the corresponding positions on the side wall of the deflector 2 , the two holes are symmetrical about the center of the spinne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com