Winding device and method for improving appearance of cast film

A winding device and casting film technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., and can solve problems such as indentation, air bubbles, and bursting ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

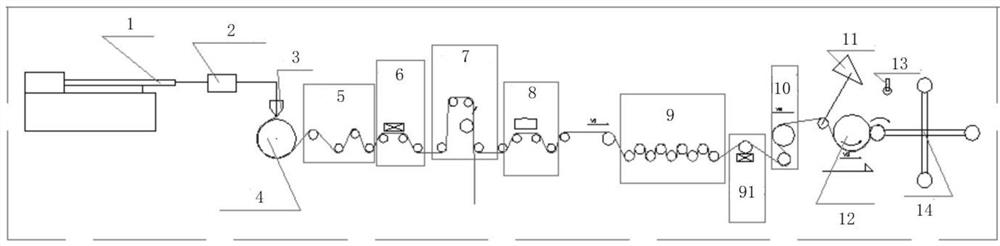

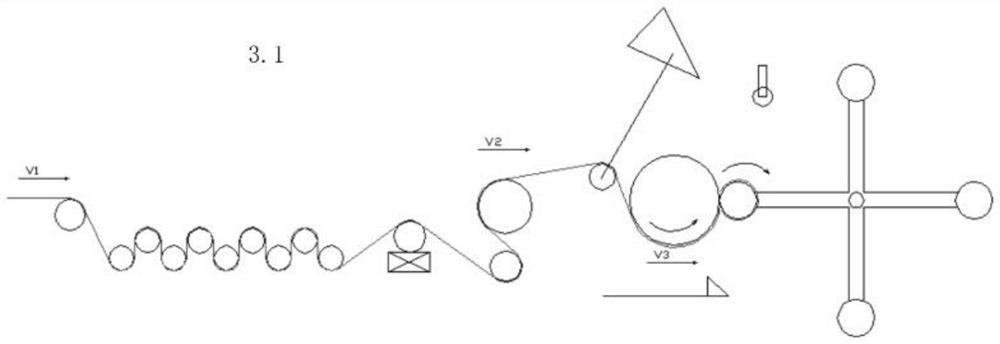

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be described below in conjunction with specific embodiments.

[0024] The traditional technology film is non-stop when winding, the specific operation is as follows:

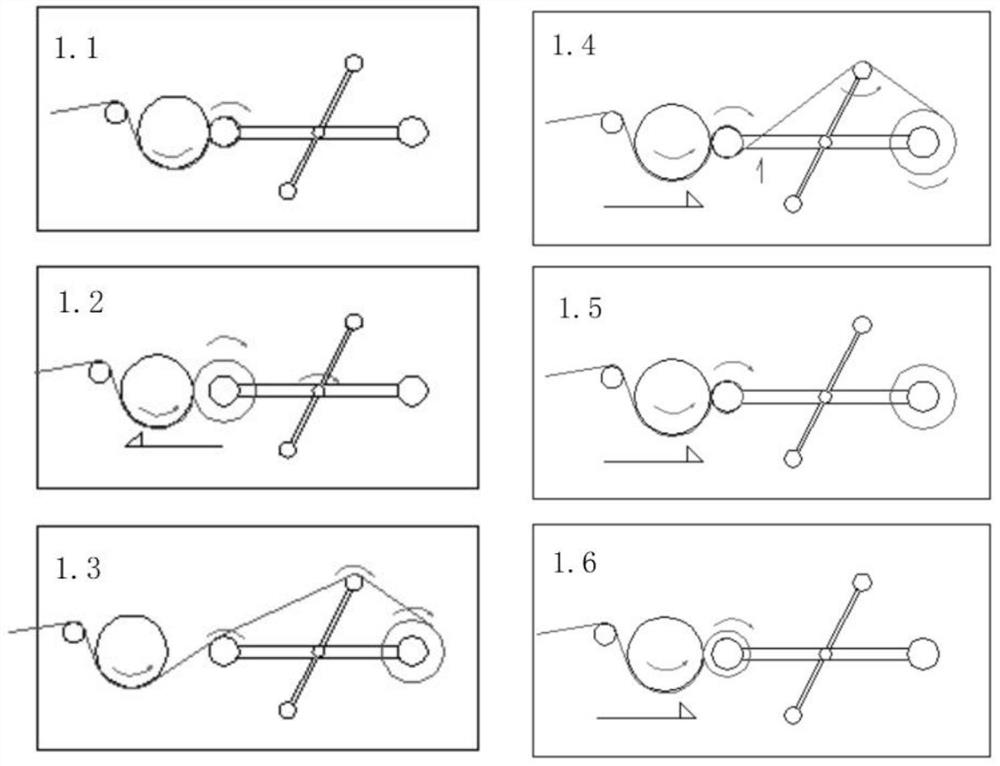

[0025] Operation 1: if Picture 1-1 .1, start winding;

[0026] Operation 2: if Picture 1-1 As shown in .2, when the number of meters of winding film reaches the length of changing rolls, the winding pressure roller moves to the left; the winding shaft rotates by itself through power to maintain tension and not unwind;

[0027] Operation 3: if Picture 1-1 As shown in .3, the winding reel frame rotates clockwise, and the rewinding reel with film rotates by itself through power to maintain tension and not unwind;

[0028] Operation 4: if Picture 1-1 As shown in .4, the winding pressure roller moves to the right. When it is pressed to the core on the winding shaft B (the core is coated with glue or double-sided tape), the film rolls on the core, and the film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com