A combined storage box and its manufacturing device

A storage box and pre-cutting technology, which is applied in the field of manufacturing combined storage boxes, can solve problems such as consumer threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

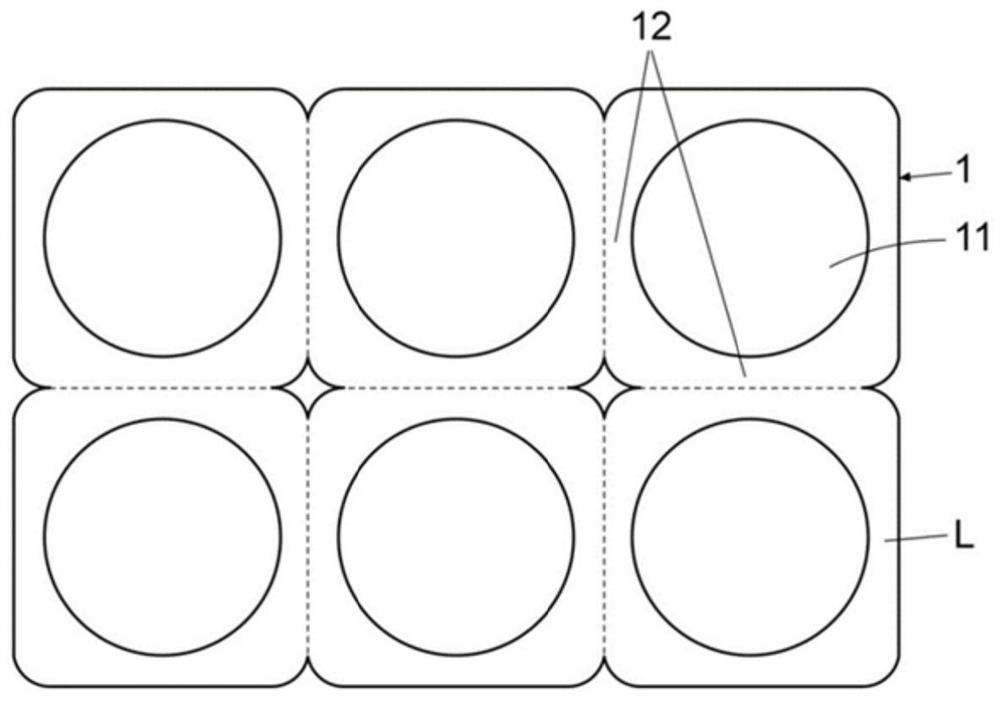

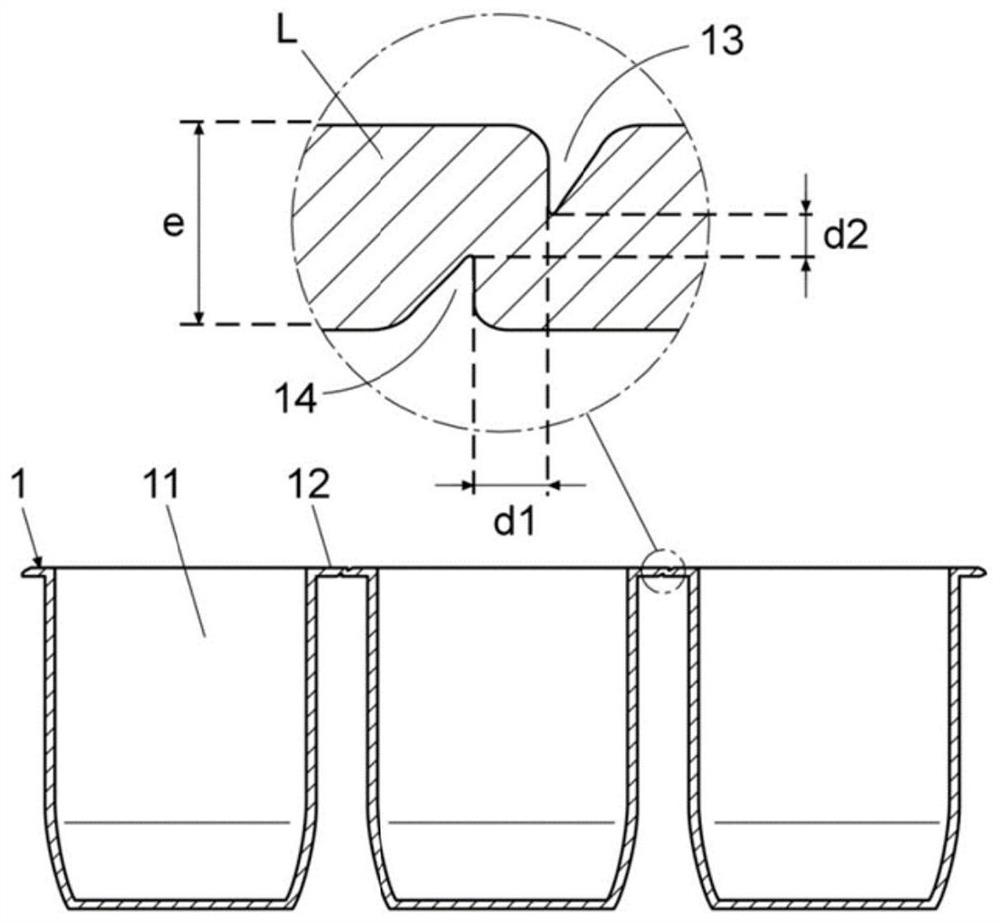

[0031] see figure 1 and figure 2 , the combination containing box is formed by a plastic plate L, in this embodiment, the plastic plate L includes a layer of PET (polyethylene terephthalate).

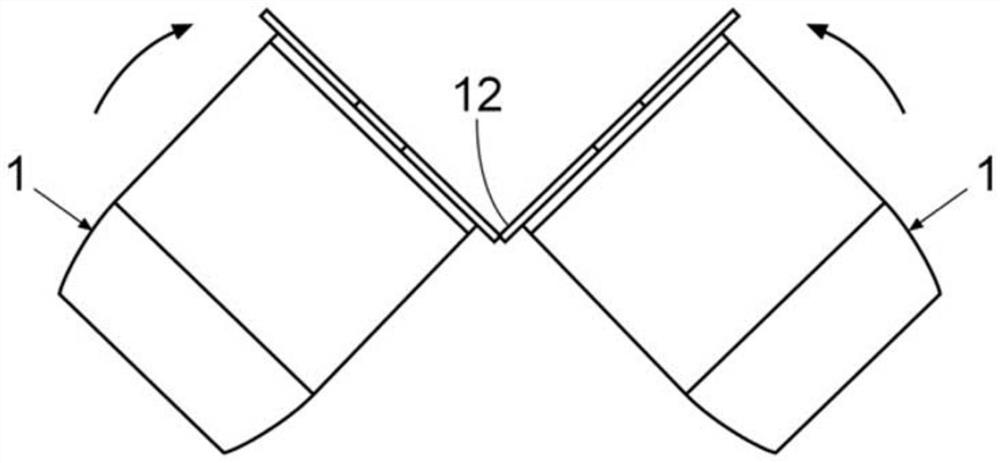

[0032] The composite storage box 1 includes a group of independent storage boxes 11 interconnected by connecting bridges 12 , the connecting bridges 12 have a predetermined thickness e and are formed by the PET sheet L.

[0033] In a particular embodiment, the thickness e of the connecting bridge is between 0.7 mm and 1.3 mm.

[0034] Such as figure 2 As shown in the partially enlarged diagram, the connecting bridge 12 is provided with an upper pre-cut line 13 and a lower pre-cut line 14, the two pre-cut lines are parallel in the horizontal direction and separated laterally, and the two pre-cut lines are separated in the horizontal direction A horizontal distance d1, the value range of the horizontal distance d1 is between 45% and 55% of the thickness e of the connecting bridge; tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com