A conductive glass edge breaker

A conductive glass, all-in-one technology, used in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting the performance of conductive glass, damaging the conductive film, occupying space, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

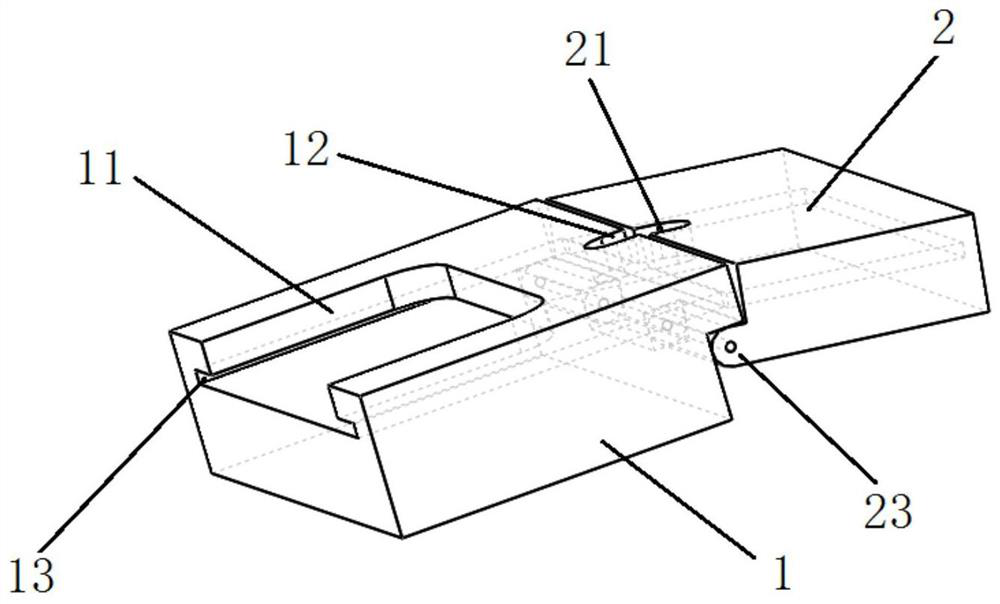

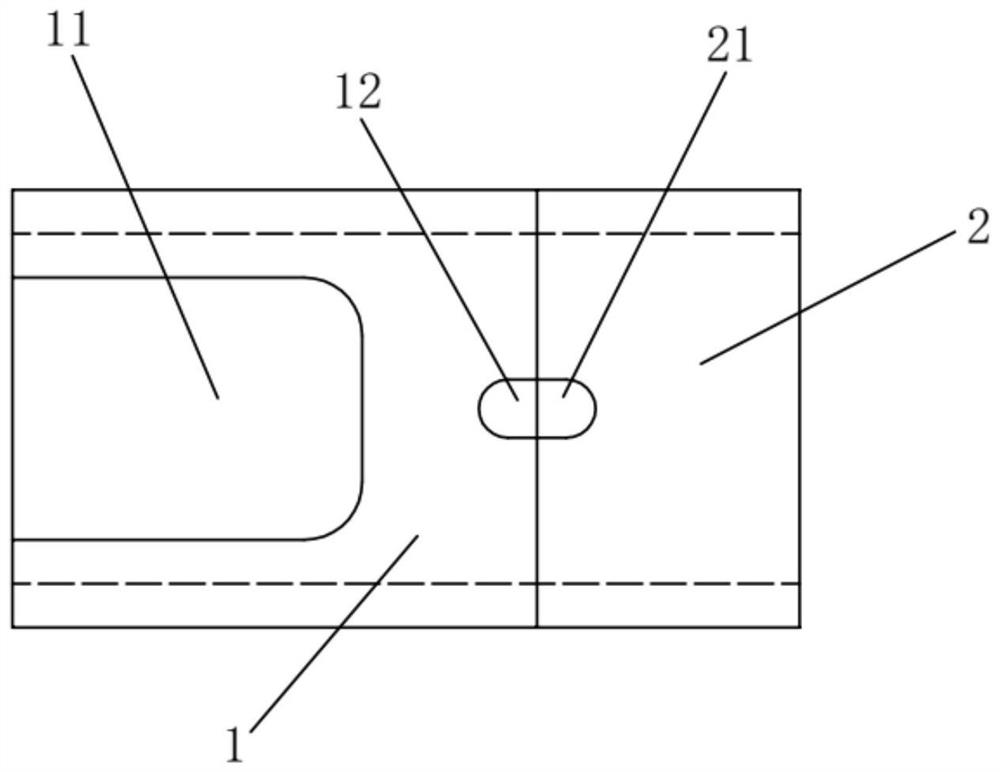

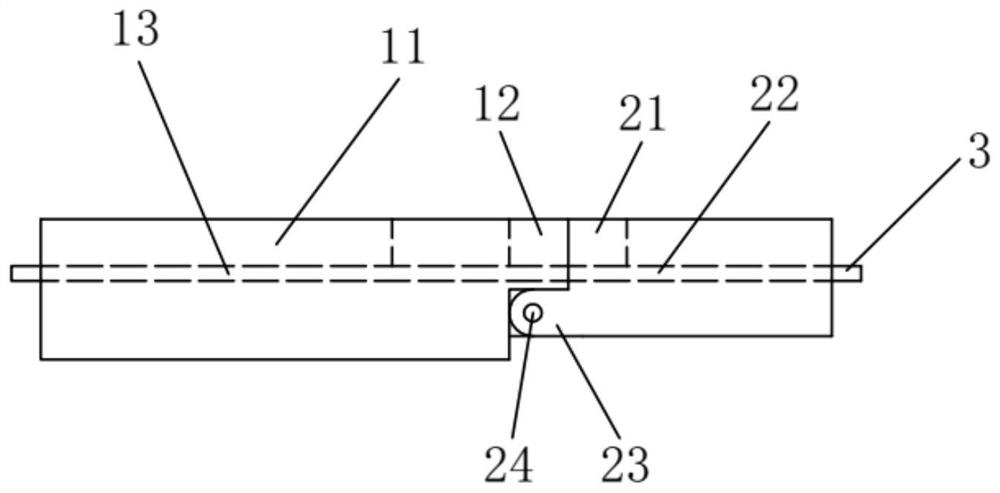

[0016] Please refer to Figure 1 to Figure 4 , the embodiment of the present invention provides a kind of conductive glass edge breaker, is suitable for laboratory use, is used for breaking off the conductive glass with scratch, and the scratch on the described conductive glass 3 is preferably cut by a professional glass cutter Marked out, the conductive glass edge breaker includes a first through-board 1 and a second through-board 2 arranged in front of and behind the first through-board 1 and independent of each other.

[0017] Please refer to Figure 1 to Figure 4 , the first penetration plate 1 includes a first penetration portion 1a and a first base 1b arranged up and down and integrally formed with each other, the thickness of the first base 1b is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com