Re-reeling machine capable of reliably and tidily cutting paper

A rewinding machine, a reliable technology, applied in the field of rewinding machines, can solve the problems such as the skew of the core tube 7, the inability to tighten the paper, and the uneven force on the paper, so as to achieve the effect of neat fracture and avoid uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

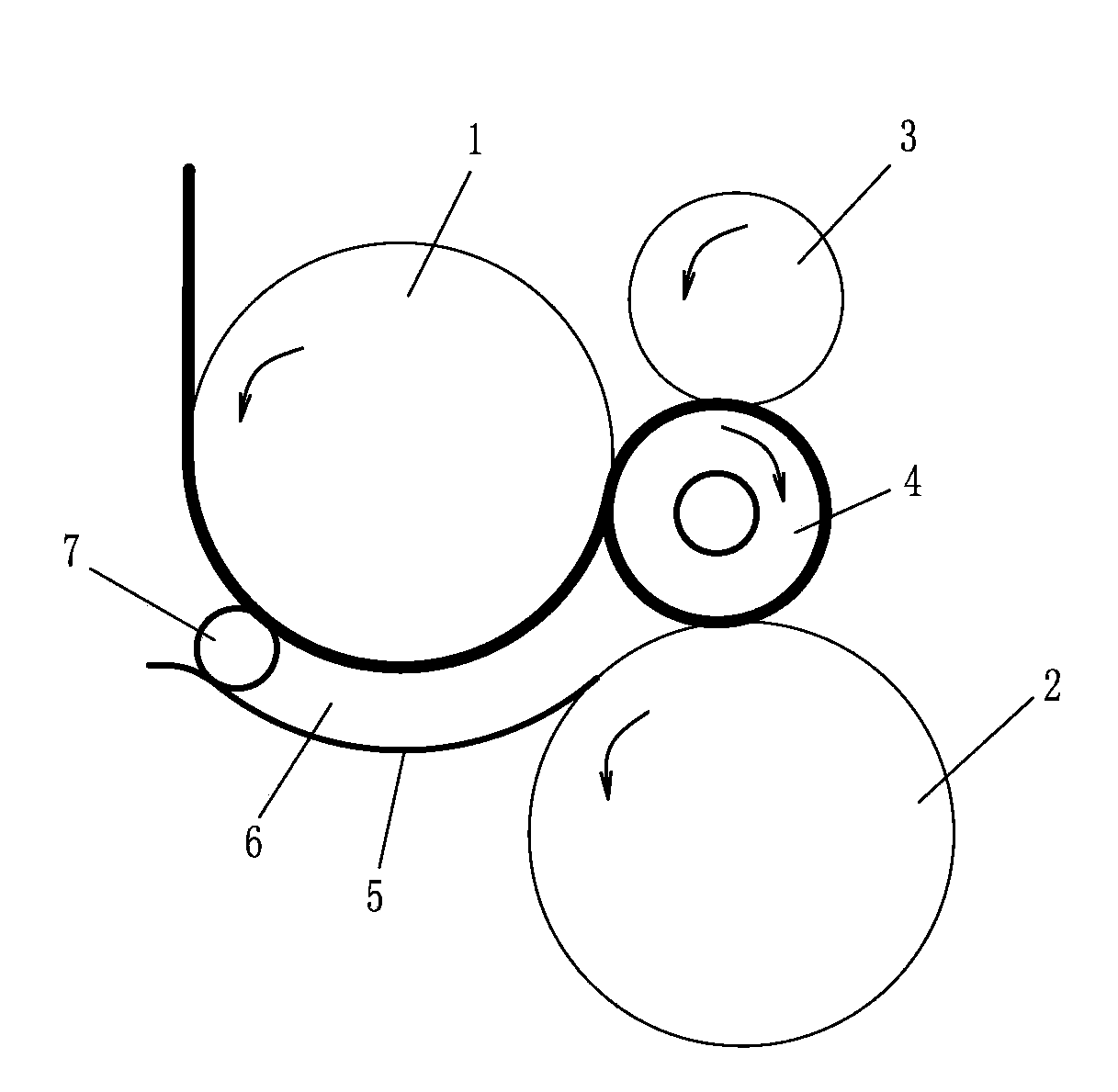

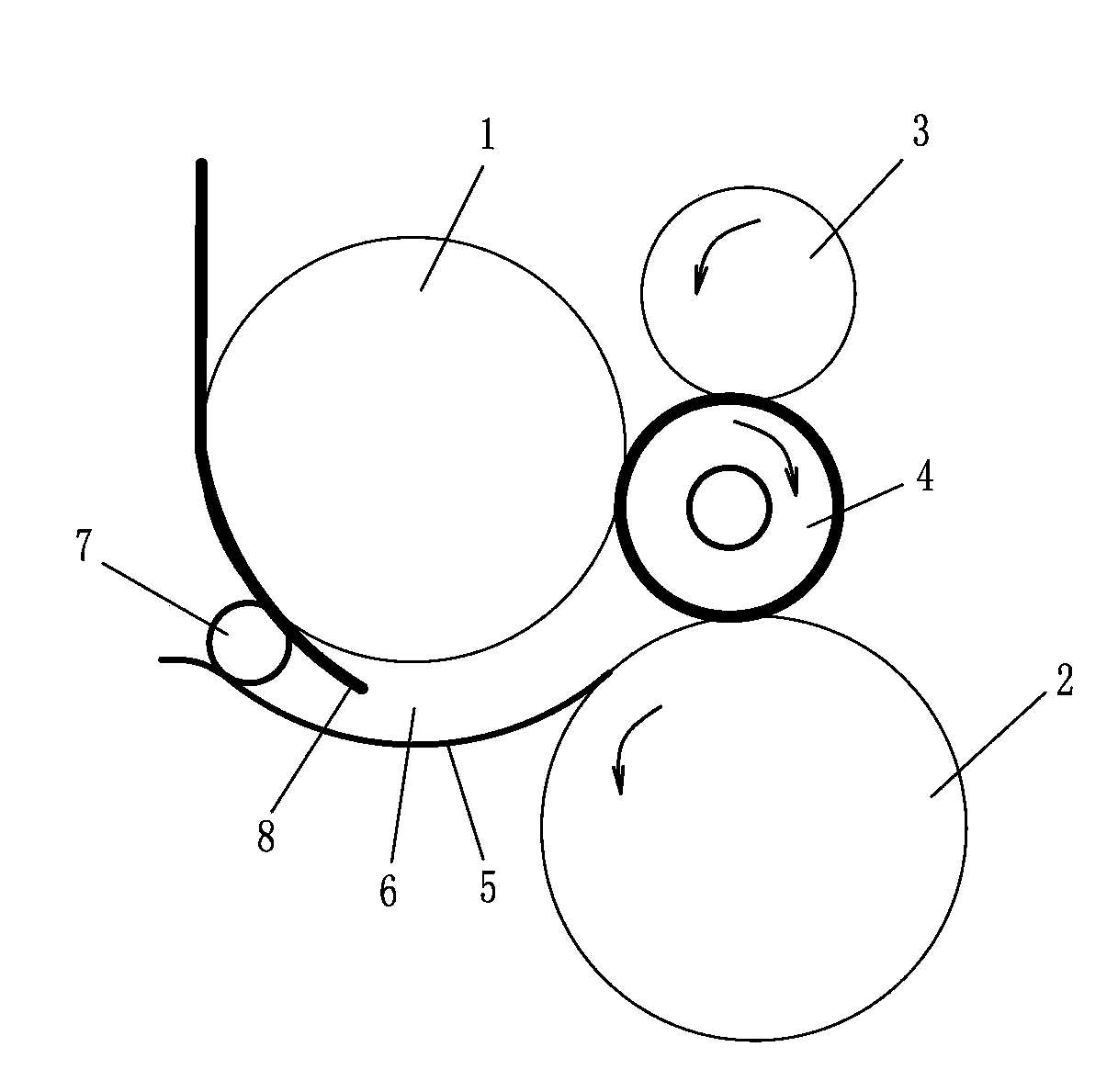

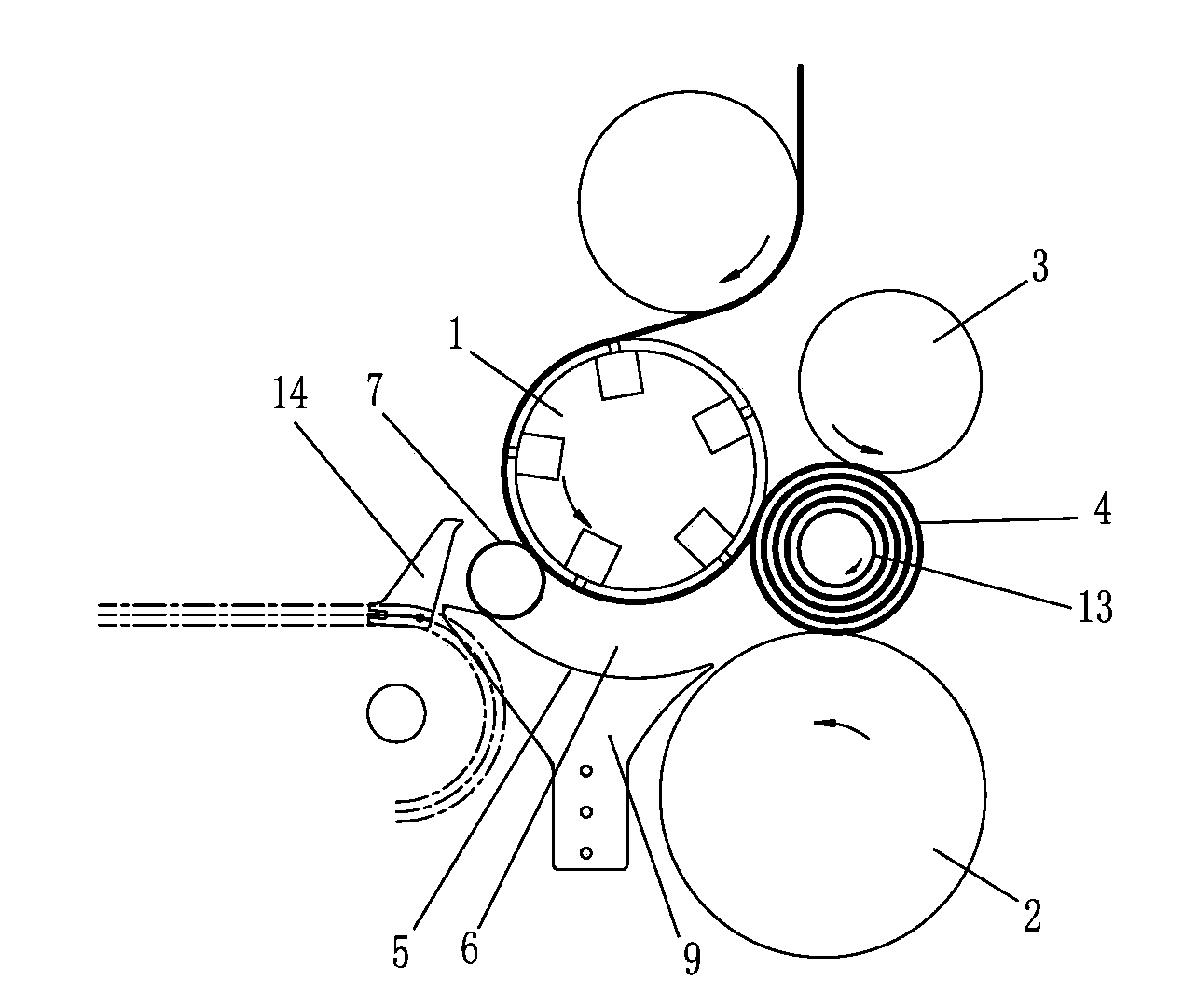

[0024] see image 3 According to a rewinding machine provided by the present invention, it comprises a rewinding upper roll 1, a rewinding bottom roll 2 and a paper pressing roll 3, the three of which jointly rotate with a paper roll 4, and the cylindrical surface of the rewinding upper roll 1 and A fixed curved surface 5 approaches each other to form a core tube channel 6 . The curved surface 5 in this embodiment is the top surface of a bracket 9, and the bracket 9 is fixedly connected with the frame of the rewinder.

[0025] see Figure 4 and Figure 5 , The cylindrical surface of the rewinding upper roller 1 has a smooth surface 18 that protrudes slightly from the friction surface 17 of the roller body with multiple turns. The height of the smooth surface 18 protruding from the friction surface 17 depends on the paper material of the paper roll. The thicker the paper, the greater the degree that the smooth surface 18 protrudes from the friction surface 17. The thinner th...

Embodiment 2

[0029] see Figure 8 In this embodiment, on the basis of Embodiment 1, a core tube damping mechanism is added at the entrance of the core tube channel 6 . The core tube damping mechanism of the present embodiment is a shift fork 10 arranged at the entrance of the core tube passage 6, such as Figure 9 As shown, when the core tube 7 is just pressed against the rewinding upper roller 1, the shift fork 10 presses against the core tube 7. Under the top pressure of the shift fork 10, it can be further ensured that the core tube 7 will not be driven by the rewinding upper roller 1 to roll.

[0030] As a best practice, see Figure 10 In this embodiment, the portion of the shift fork 10 in contact with the core tube is provided with a saw-tooth-shaped rough surface 11, which is more helpful in restricting the core tube 7 from rolling.

[0031] As a further improvement, see Figure 9 In this embodiment, air blowing holes 12 are provided on the cylindrical surface of the rewinding u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com