Windshield wiping device for a motor vehicle

A technology for car windows and cars, applied in the field of car window wiper devices, to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

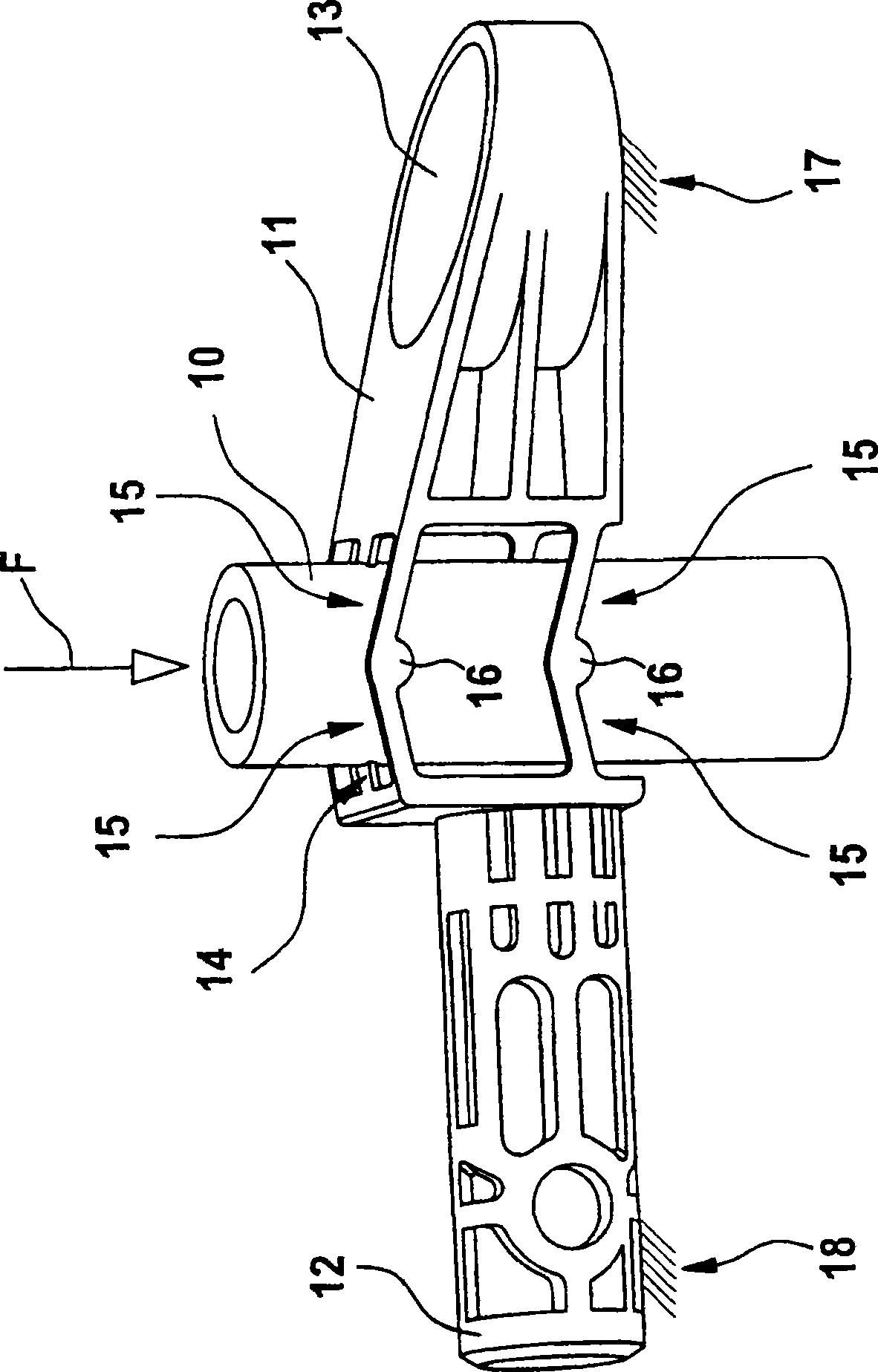

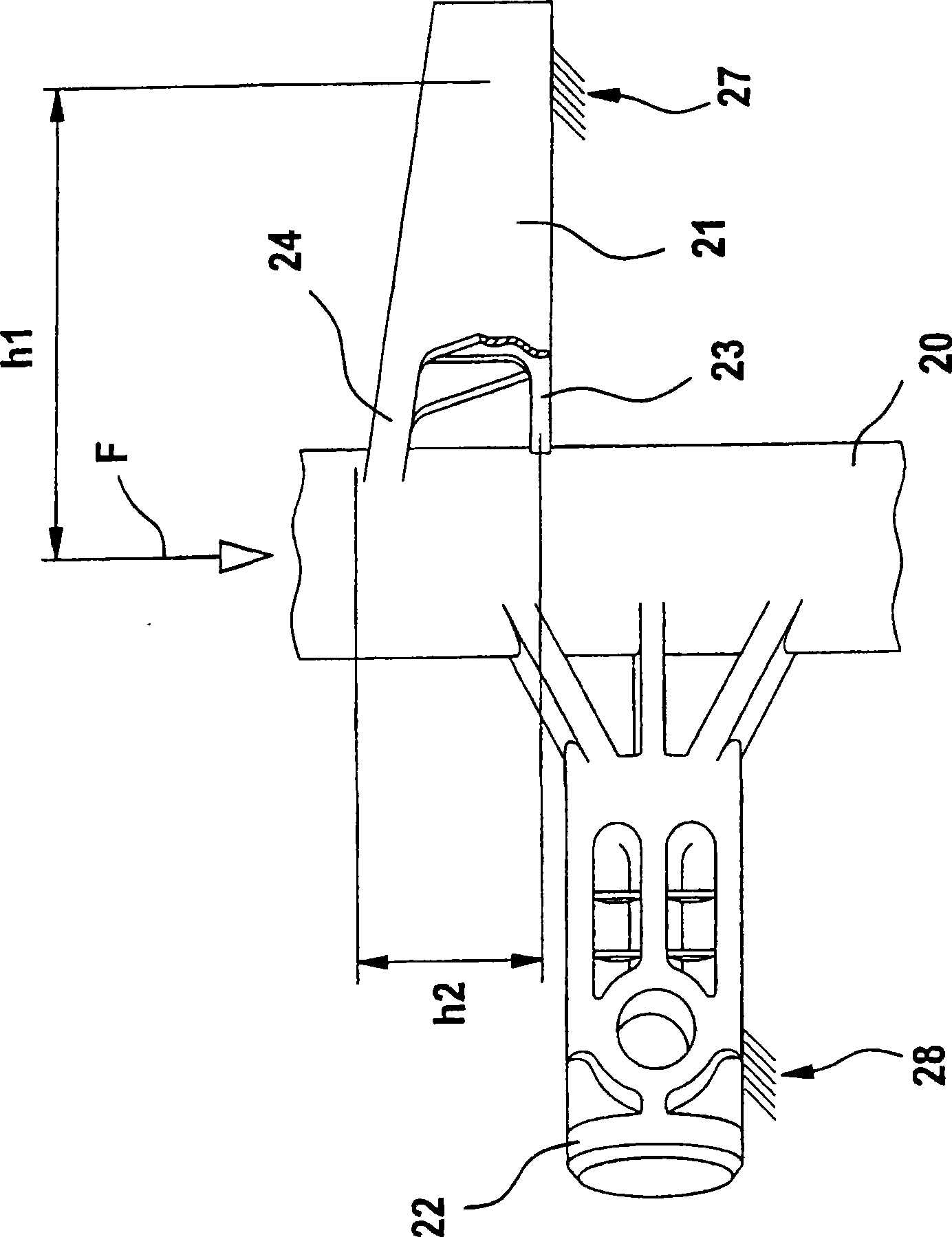

[0018] figure 1 A forming tube 10 is shown. A drive shaft, not shown in detail here, for driving a wiper arm, likewise not shown in detail here, can be inserted into the profile tube. A support element 11 and a butt end 12 are connected to the profile tube 10 . The carrier element 11 has a receiving opening 13 . Fastening means (not shown here) for fastening the carrier element 11 to a body (not shown here) can be inserted into the receiving opening. A solid fastening point 17 is formed by the connection of the support element 11 to the vehicle body. A sheet metal tube, also not shown, can be crimped (ancrimbar) onto the butt end 12 so that the butt end 12 has a firm fastening point 18 . The support element 11 and the butt end 12 are connected to the profile tube 10 via webs 14 and 15 . The strips 15 each have an elbow 16 which is connected to the profile tube 10 . When a force F, such as a collision force when hitting a pedestrian, acts on the profiled tube 10, the prof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com