A kind of automatic packaging method of roll paper feeding from bottom to top

A bottom-up, roll paper technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of harmful workers' health, low working speed, difficult maintenance and use, etc. Uniform and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

[0026] A kind of web feeding type automatic packaging method from bottom to top according to the present invention is specifically implemented in sequence according to the following steps:

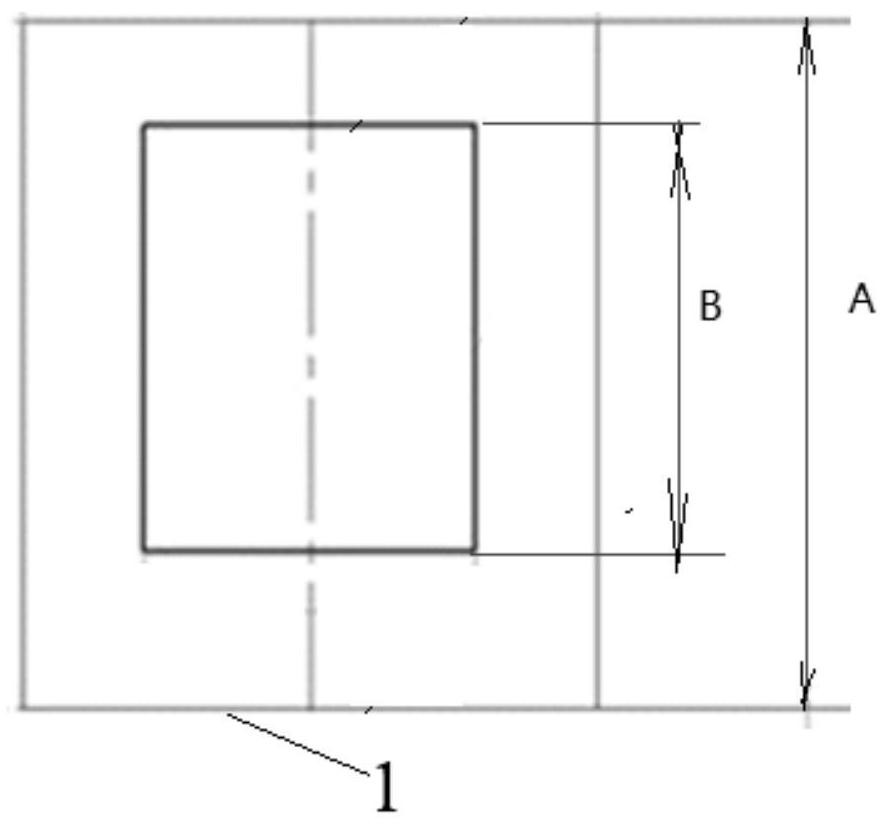

[0027] Step 1, first set the size of the roll paper 1 according to the requirement, and then adjust the installation position of the roll paper 1;

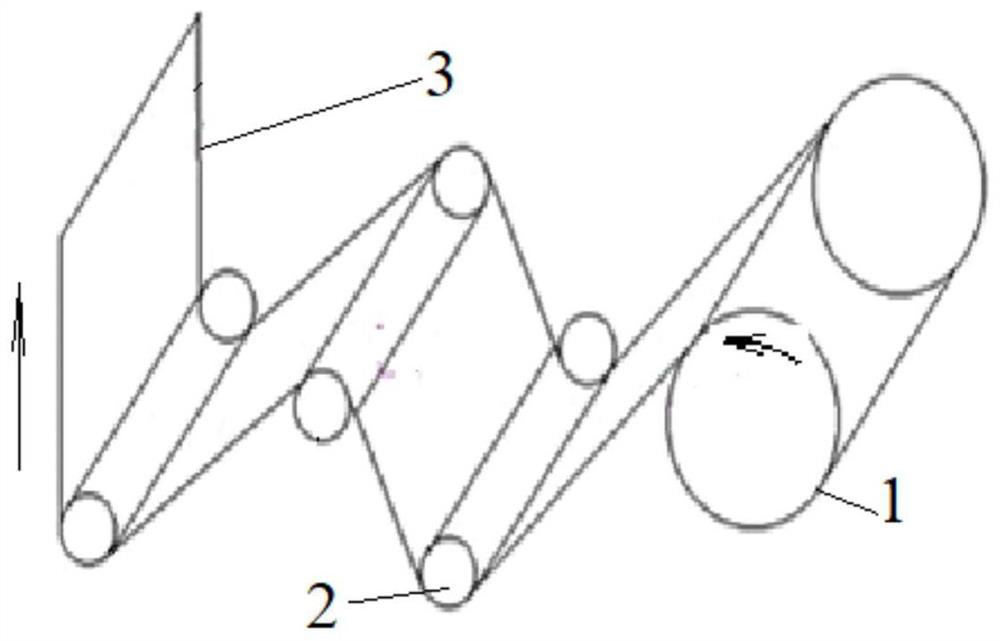

[0028] Step 2, using a guiding mechanism to pull the paper 3 of the roll paper 1 from bottom to top;

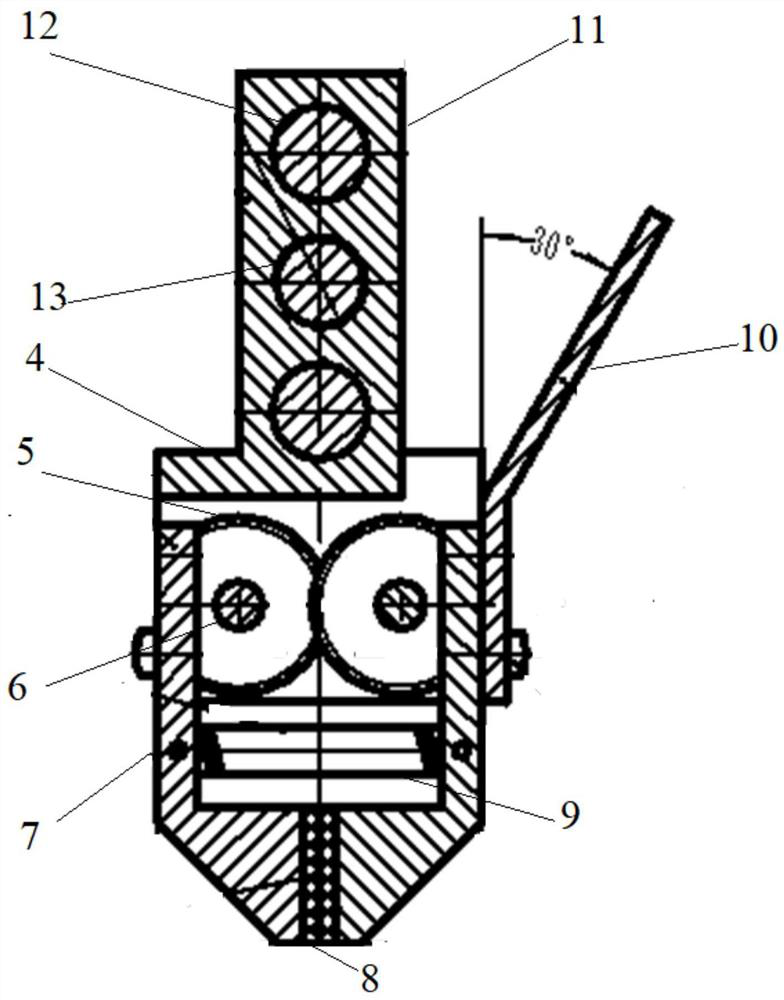

[0029] Step 3, push the stacked books to the paper;

[0030] Step 4, use the cutter to cut the paper, and pack the stacked books with the packing machine.

[0031] The automatic packing method of the web feeding from bottom to top in the present invention adopts the feeding method of bottom feeding instead of the upper feeding method, and replaces the heavy manual la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com