Large-thickness separation structure without weakening groove, stress concentration or protective cover

A technology for separating structures and weakening grooves, which is applied in aerospace equipment, aerospace vehicles, docking devices of aerospace vehicles, etc., and can solve the requirements of inability to apply high-strength aluminum alloy shells, long production and inspection cycles, and neutrality High-level problems, to achieve the effect of shortening the development and production cycle, reducing the X-ray alignment inspection process, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with embodiment.

[0027] Aiming at the shortcomings of the traditional line separation device, the present invention discloses a new network cutting and separation structure design scheme, which has the advantages of large thickness of the shell, no need to set weakening grooves, no stress concentration, and no protective cover, and can significantly improve the bearing capacity of the spacecraft separation structure. efficiency.

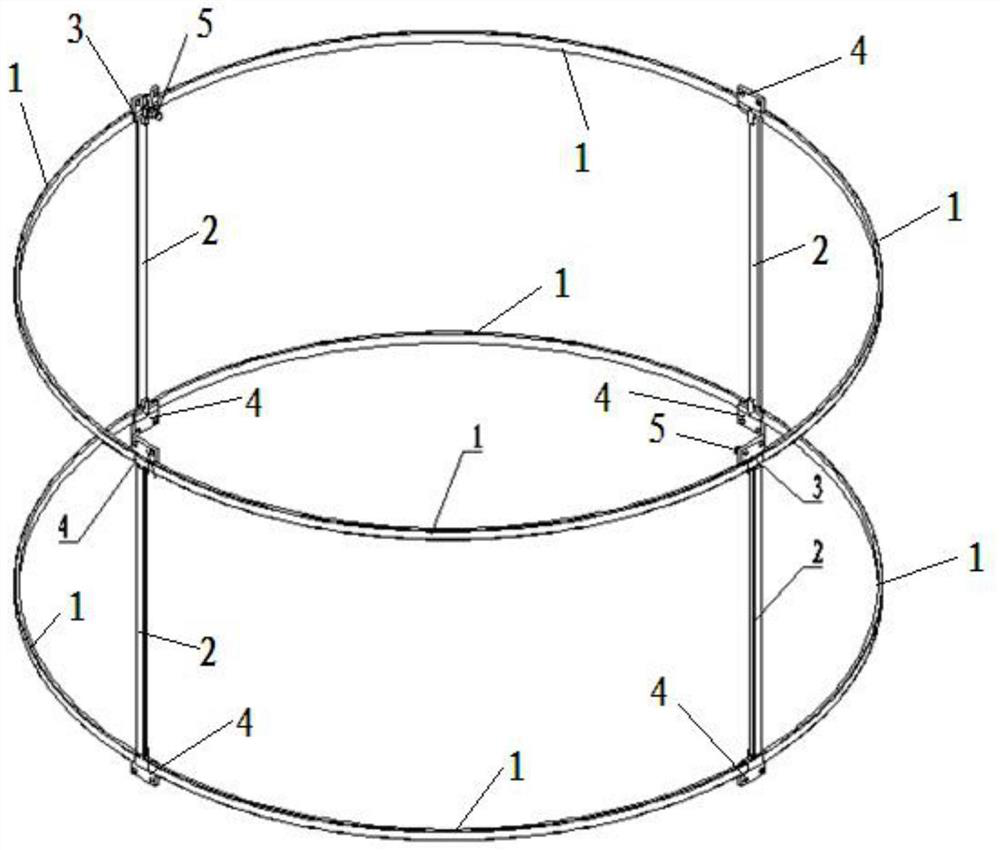

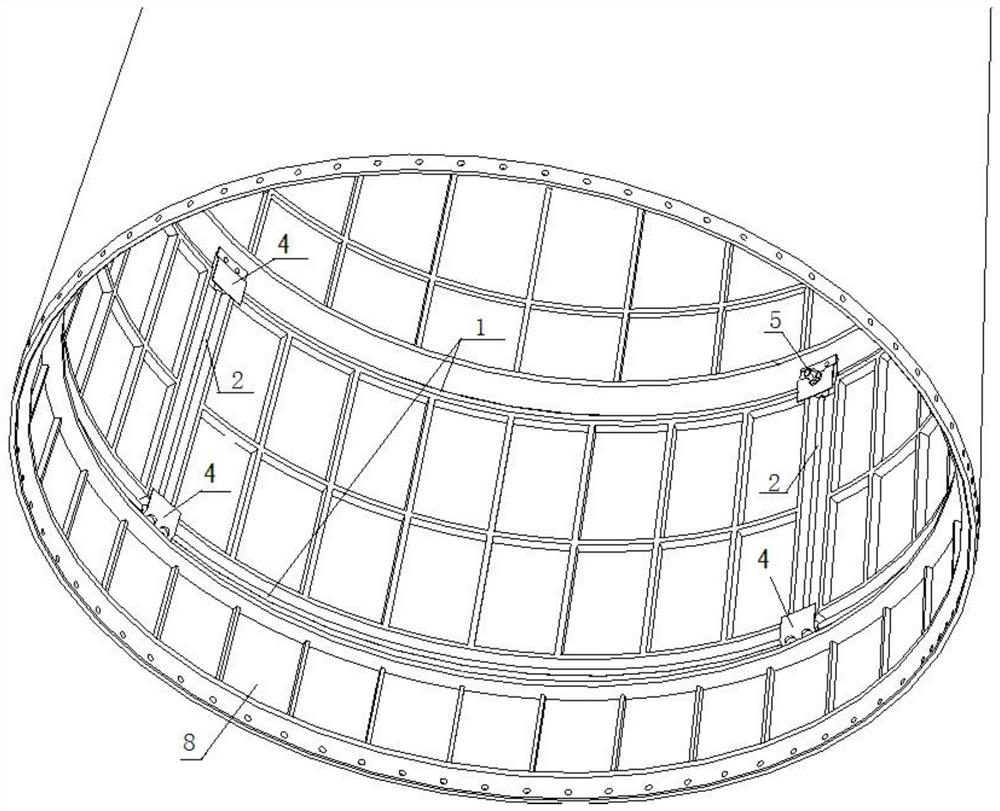

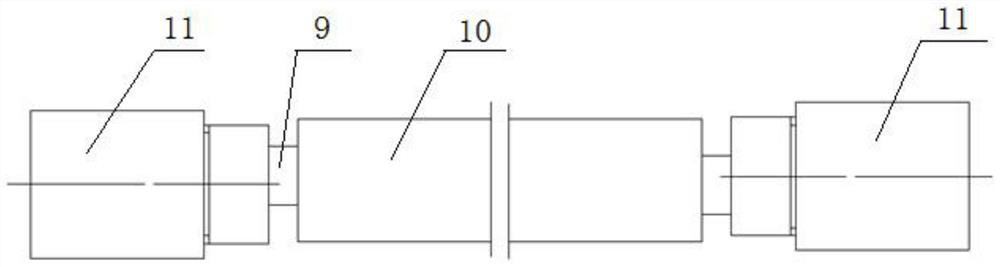

[0028] Large thickness, no weakening groove, no stress concentration, no protective cover separation structure, such as figure 1 As shown, it specifically includes 8 circumferential energy-shaping cutting cable assemblies 1, 4 longitudinal energy-shaping cutting cable assemblies 2, 2 four-way detonating assemblies 3, 6 three-way detonating assemblies 4 and 2 detonators 5; , every four ring-shaped energy-gathering cutting cable assemblies 1 are connected end-to-end to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com