Method and equipment for bubble blowing and tube breaking in glass capillary tube

A glass capillary and capillary technology, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve the problems of low production efficiency, waste of materials, and high labor intensity, and achieve high production efficiency and high forming size. Good consistency and good consistency of broken tube length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

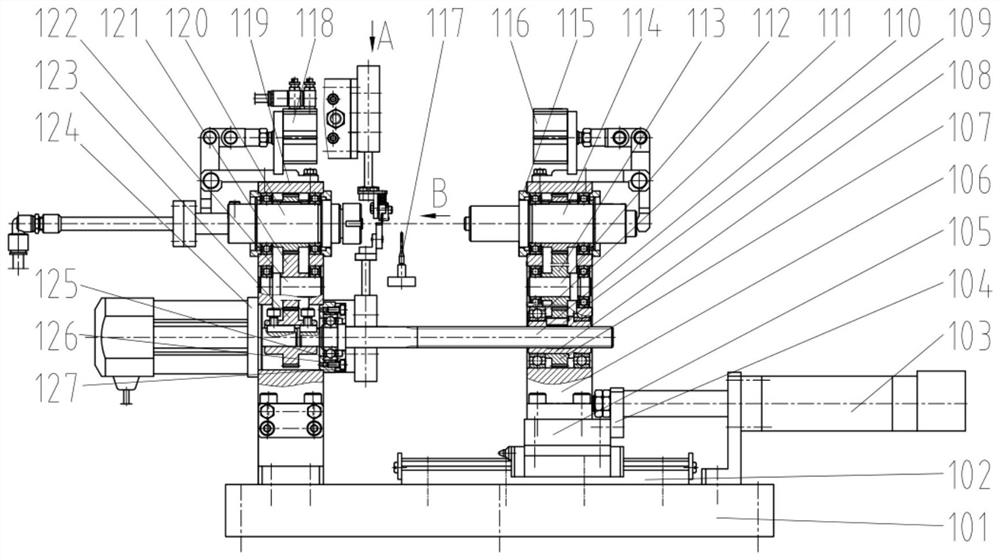

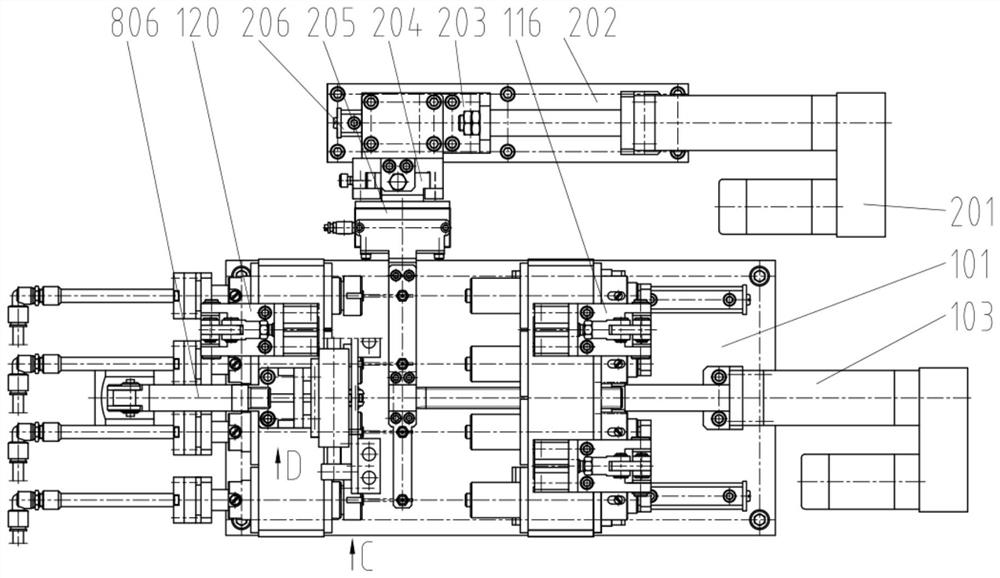

[0061] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

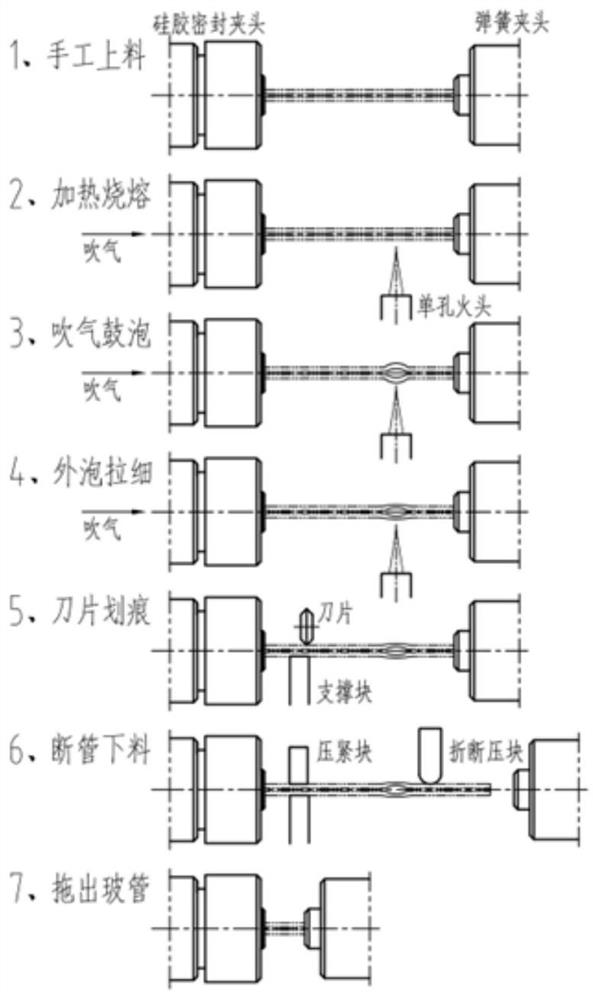

[0062] Step 1: The whole glass capillary is manually loaded in the left end chuck body, the right end of the capillary is clamped by the right end chuck, the capillary is pulled out from the left end chuck body, and the capillary is clamped by the two end chucks.

[0063] Step 2: The capillary rotates with the chucks at both ends, and the single-hole burner ignites the flame to melt the capillary.

[0064] Step 3: A certain pressure gas is introduced into the capillary, and the melting part bubbles into an ellipsoid.

[0065] Step 4: The capillary continues to be heated, the chuck at the right end moves to the right, and the bulb is stretched. The wall thickness of the outer diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com