Broach for belt cutting

A belt and cutting technology, which is applied in metal processing and other directions, can solve the problems of easy scratches on fingers, irregular fractures, and low cutting efficiency, and achieve the effects of avoiding scratches on fingers, easy operation, and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

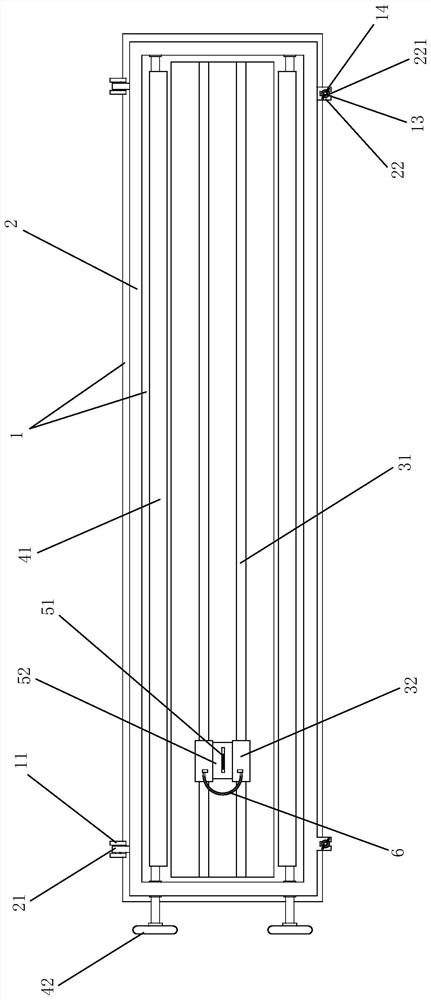

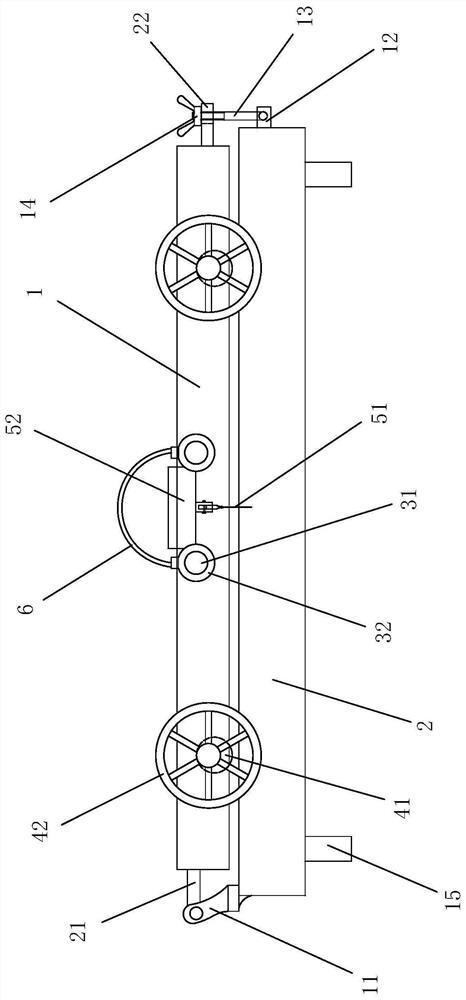

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022] combine figure 1 and figure 2 , a broach for belt cutting, comprising a bottom frame 1, a movable frame 2, a guide mechanism, a clamping mechanism and a blade assembly, the movable frame 2 is located above the bottom frame 1, and the left side of the movable frame 2 is connected to the bottom frame 1 is connected in rotation, and its right side is connected with the detachable fixing of the underframe 1. Two sets of supporting legs are respectively provided on the left and right sides below the bottom frame 1 . Each set of supporting legs includes two supporting legs 15 arranged longitudinally at intervals, and the upper end of each supporting leg 15 is fixedly connected with the chassis 1 as a whole.

[0023] Specifically, the bottom frame 1 and the movable frame 2 are rectangular planar frames made of square tubes. The two ends on the left side of the bottom frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com