Railway train set quick restart device

A technology for EMUs and equipment, which is applied to railway car body components, equipment fixed to the track, transportation and packaging, etc. It can solve the problems that the characteristics of EMUs cannot be applied, achieve safe and reliable functions, and increase the lateral movement distance , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

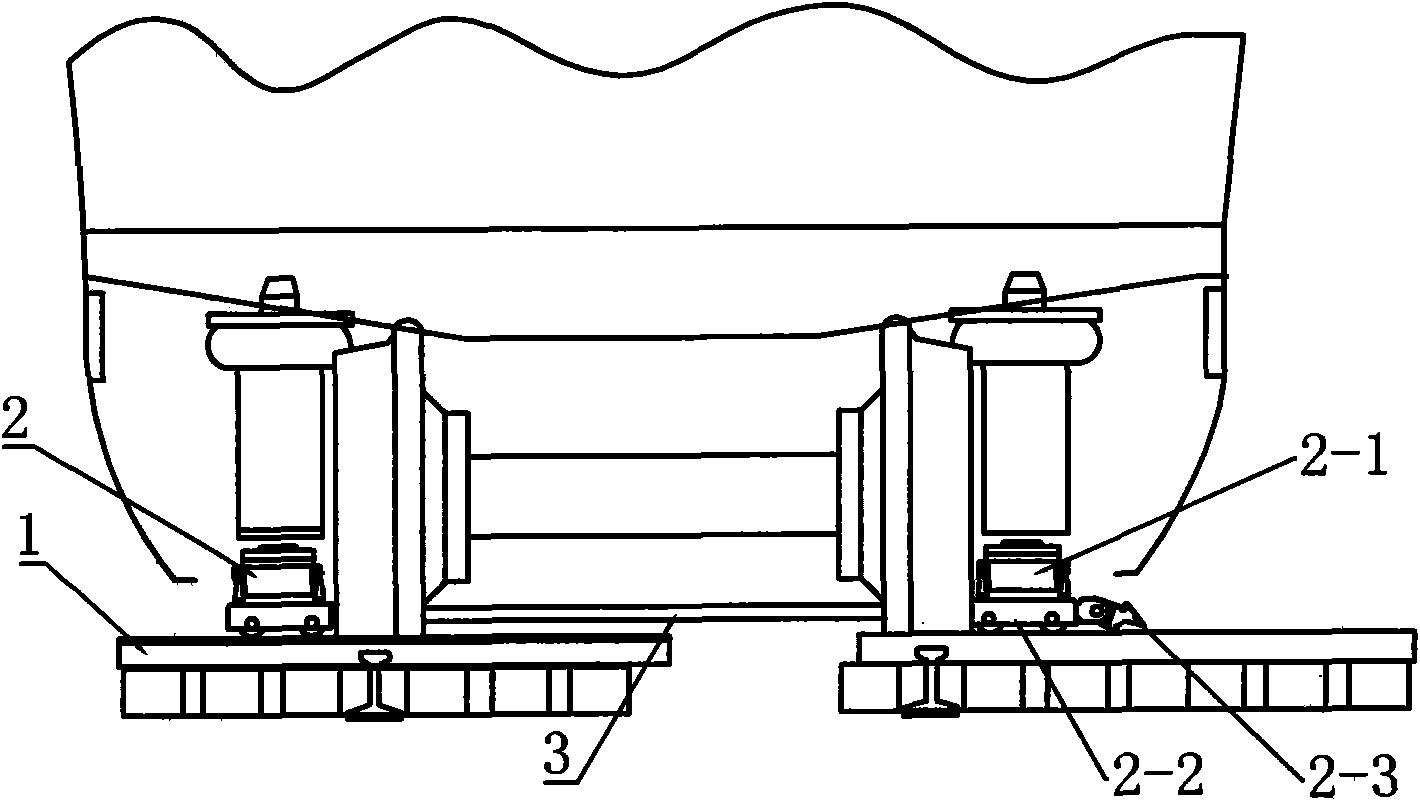

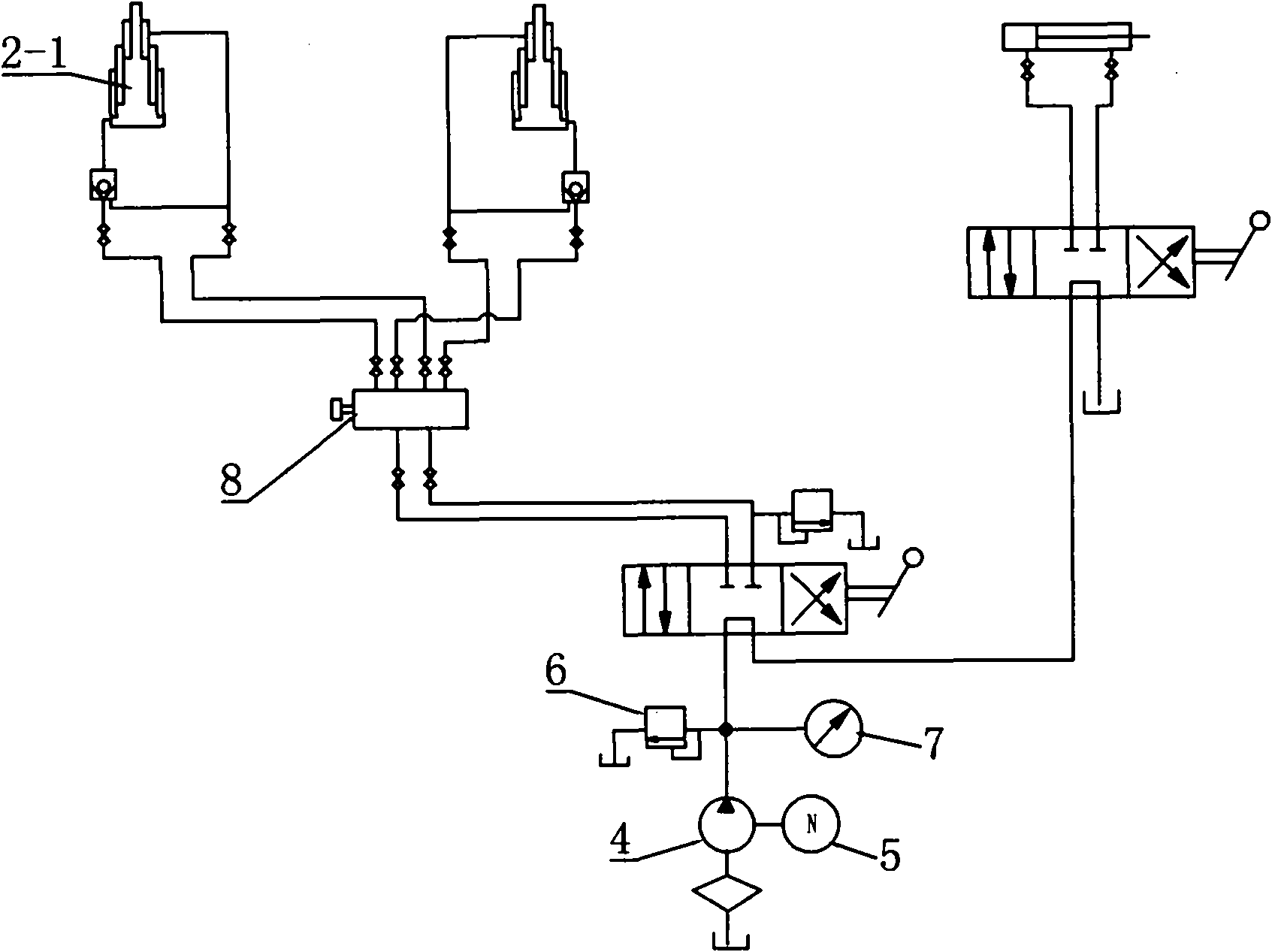

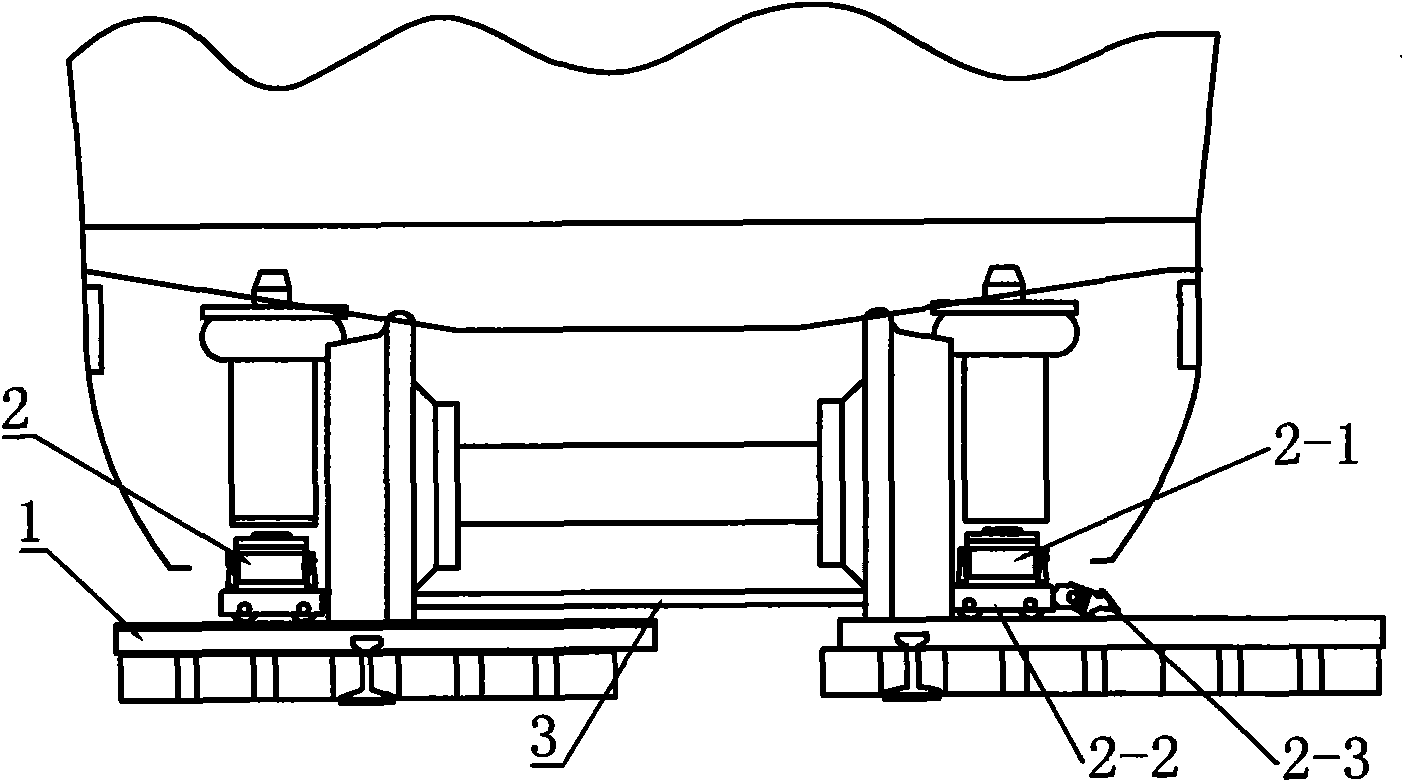

[0019] like figure 1 , figure 2 As shown, a kind of rapid recovery equipment for railway multiple units of the present invention comprises a mobile hydraulic station, a hydraulic reversing console, a rerail bridge 1 and a jacking mobile device 2, and the jacking mobile device 2 is arranged on the rerail bridge 1, and the rerailing bridge 1 Rail bridge 1 adopts military industry armor plate. Among them, the jacking mobile device 2 is mainly composed of two or more multi-stage hydraulic jacks 2-1 and traversing trolleys 2-2 arranged on the outside of two parallel rails, and the multi-stage hydraulic jacks 2-1 are fixed on the traversing trolleys 2-2 On, the traversing trolley 2-2 is provided with a rotary push-pull head 2-3 that drives it to move back and forth along the double rail bridge. In this embodiment, a three-stage hydraulic jack is used as the multi-stage hydraulic jack. The rotary push-pull head 2-3 is composed of a hydraulic cylinder connected to the hydraulic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com