Free mobile gate seat tower crane

A technology of tower cranes and portal towers, which is applied to cranes and other directions, can solve the problems of adaptability, insufficient efficiency, high work efficiency, and difficulty in changing the height of the machine body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with embodiment. The examples are used to illustrate the present invention, and do not limit the scope of protection of the present invention in any way.

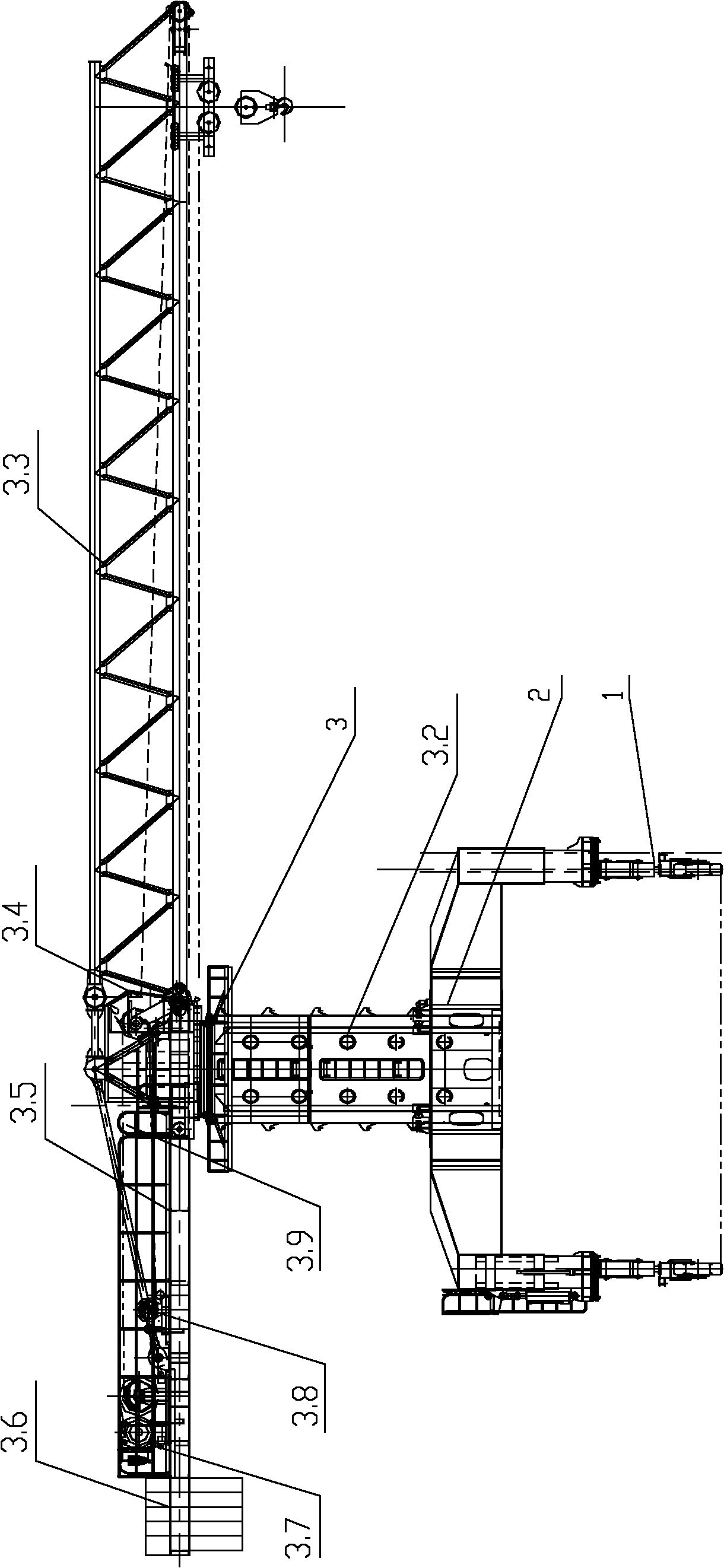

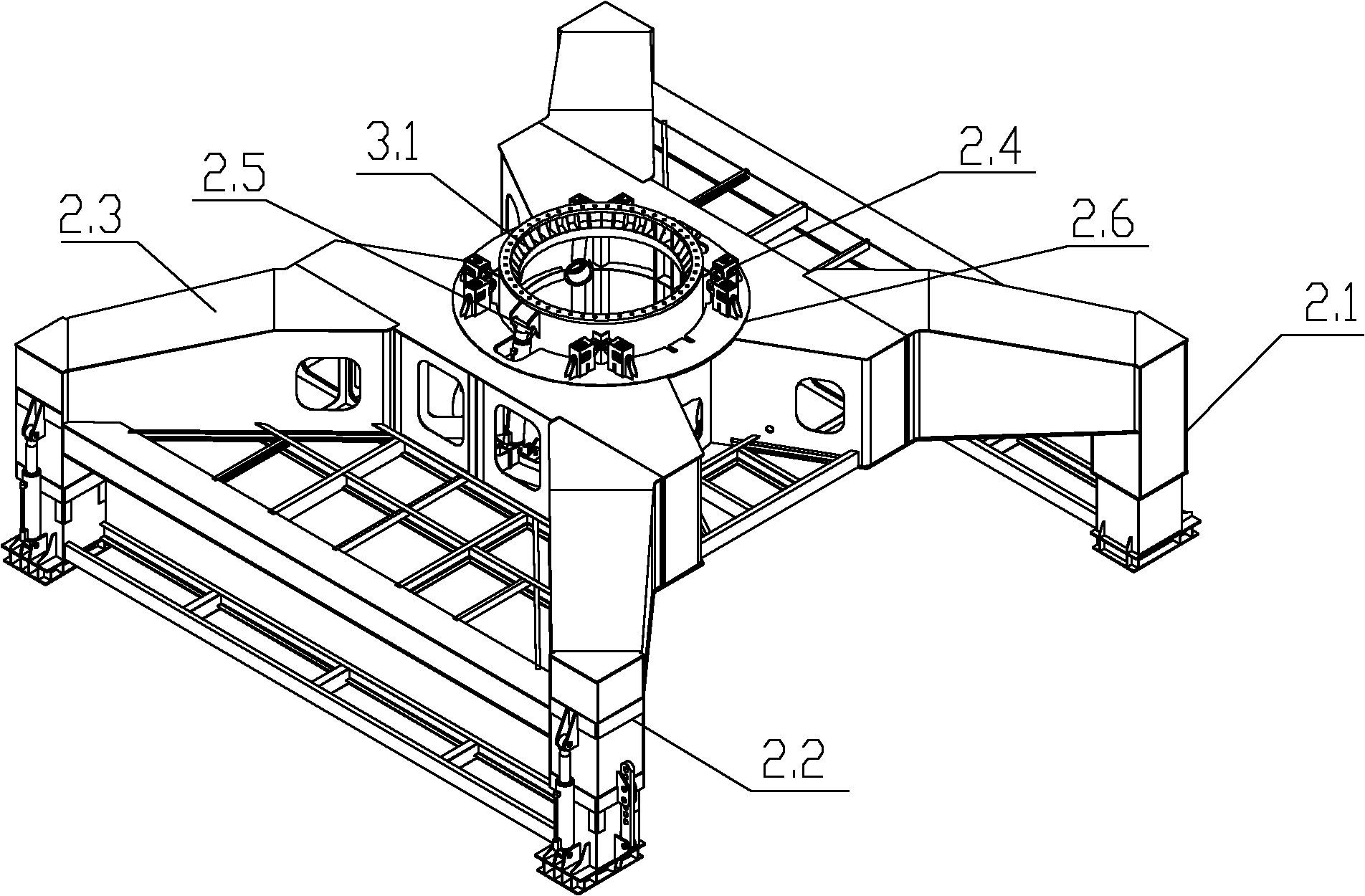

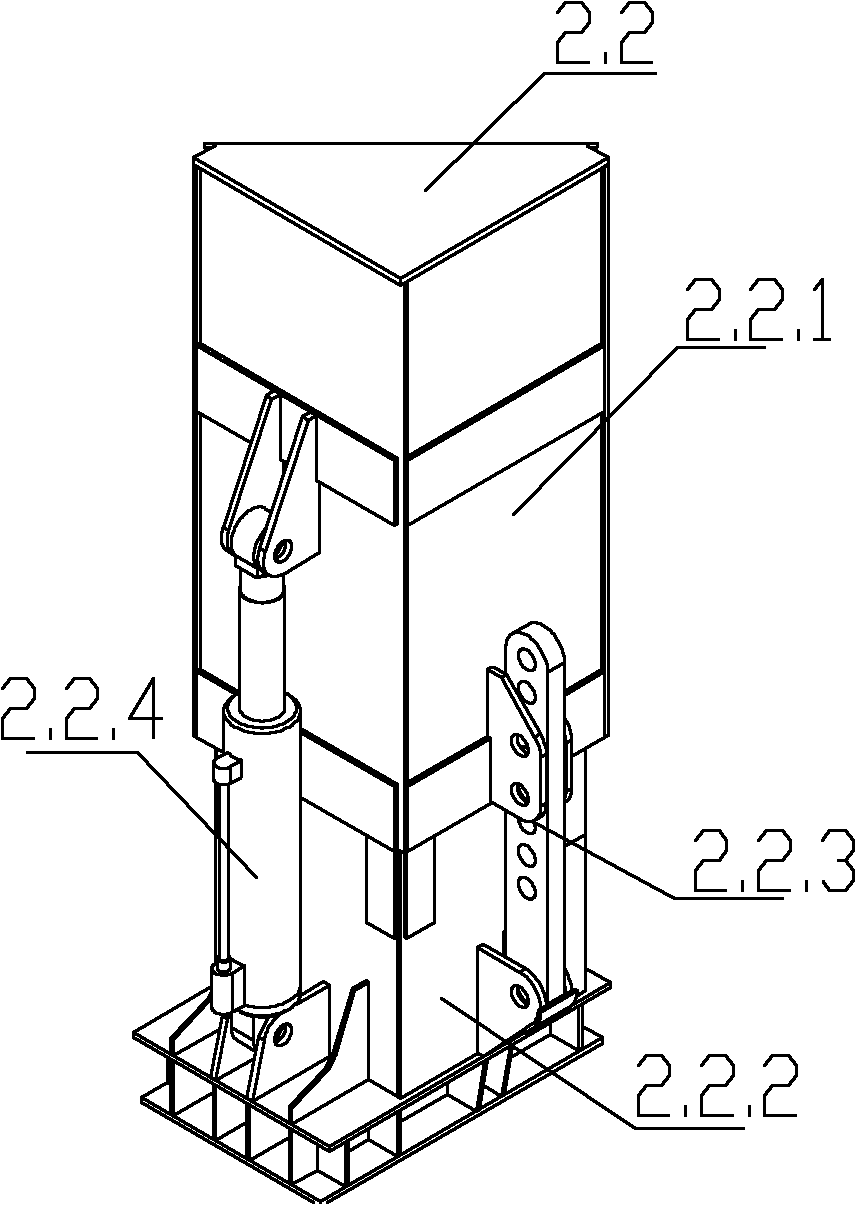

[0032] combine Figure 1 to Figure 9 .

[0033] figure 1 It is a schematic diagram of the overall structure of a free-moving portal tower crane, as shown in the figure, including a traveling mechanism 1, a tower crane mechanism 3, and a portal supporting device 2 connecting the traveling mechanism 1 and supporting the tower crane mechanism 3; the traveling mechanism 1 is the trackless tire traveling mechanism, the tower crane mechanism 3 is installed on the door seat supporting device 2, and the door seat supporting device 2 is installed on the four groups of traveling mechanisms 1 to realize movement.

[0034] The tower crane mechanism 3 includes a foundation tower column 3.1 connected to the tower crane support platform 2.6, a tower crane mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com