Rapidly-opened/closed check valve device for gas pipeline

A technology of gas pipelines and check valves, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, granular/powdered fuel gasification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

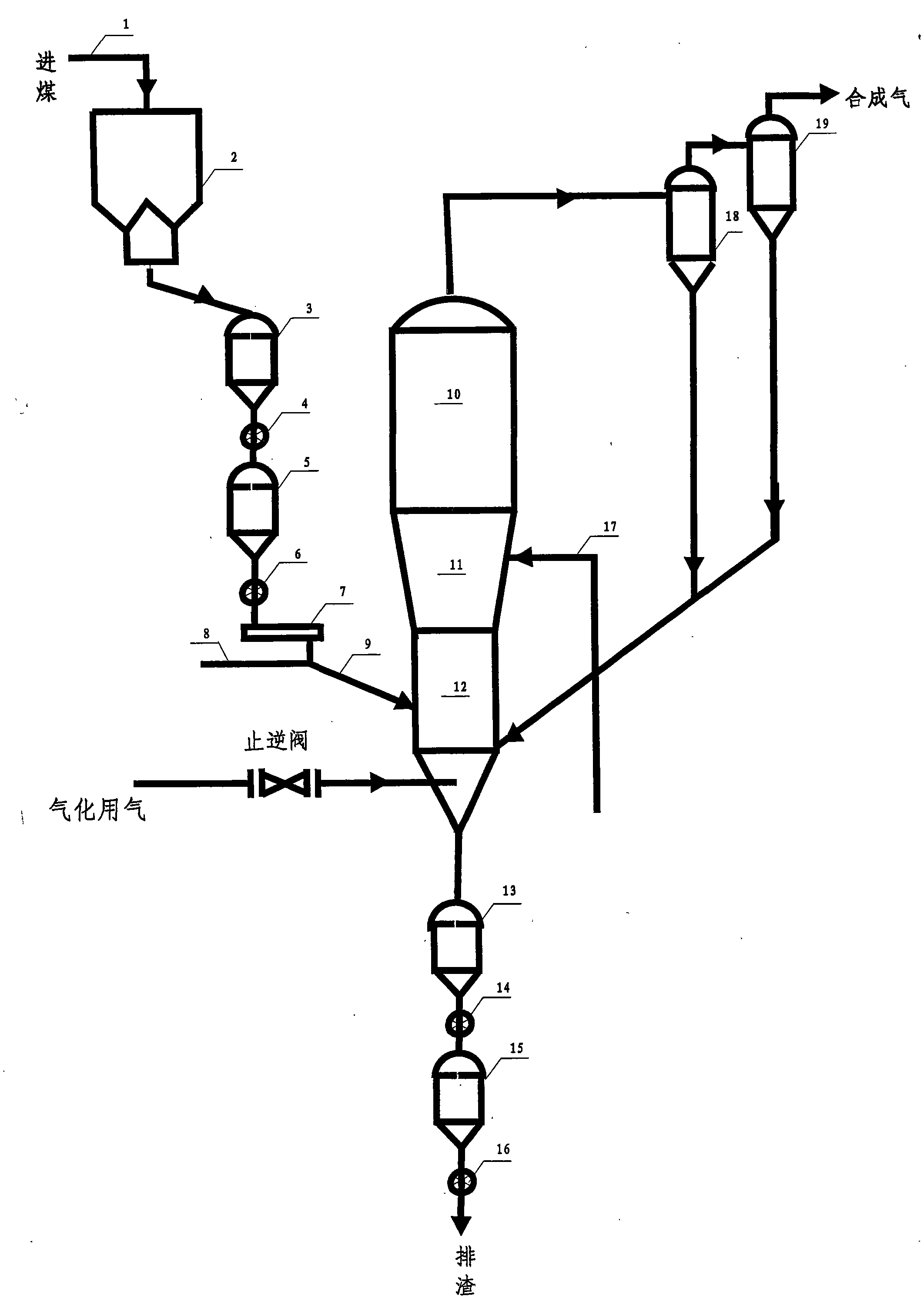

[0018] Attached below figure 1 The structure and working principle of the patent of the present invention are further described.

[0019] The patent of the present invention includes a fluidized bed or spouted bed device 12 connected up and down and multiple fly ash gasification devices 10 and 11 . The coal bunker 2 is sent into the furnace by the screw coal feeder 7 through the interconnected coal locks 3 and 5 and star valves 4 and 6 . The coal inlet pipes 8 and 9 communicate with the dense phase area of the fluidized bed, and the coal inlet pipes are also provided with blowing gas. The multiple fly ash gasification devices 10 and 11 are in communication with a primary cyclone dust collector 18 . An outlet of the primary cyclone dust collector communicates with the dense phase zone 12 of the fluidized bed through a high temperature ball valve and a rotary leg. The other outlet of the primary cyclone dust collector 18 communicates with the secondary cyclone dust collecto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap