Annular space continuous nitrogen injection auxiliary heat insulation method for offshore thermal recovery

An annulus, nitrogen injection technology, applied in the direction of fluid production, earthwork drilling, wellbore/well components, etc., to reduce the probability of casing damage, increase elastic energy, and improve water recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

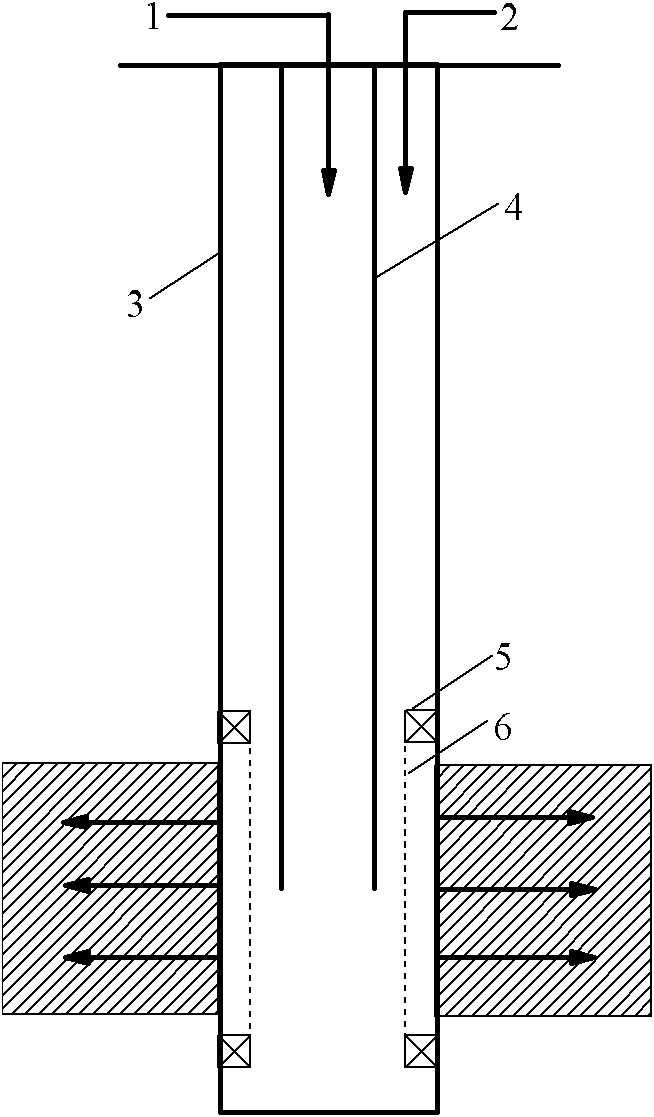

[0027] The present invention is essentially different from the annular space nitrogen filling technology in the above-mentioned patents in terms of purpose and process. like figure 1 As shown, the present invention continuously injects nitrogen 2 into the annulus between the heat-insulated oil pipe 4 and the casing 3 under the premise of utilizing the heat-insulated oil pipe 4 during the thermal recovery and heat injection period, and the nitrogen 2 is in the heat-insulated oil pipe 4. The output end merges with the injected thermal fluid 1 and enters the formation.

[0028] In addition, on the output end of the casing 3, a screen 6 is installed through the top packer 5, so as to play the role of sand control.

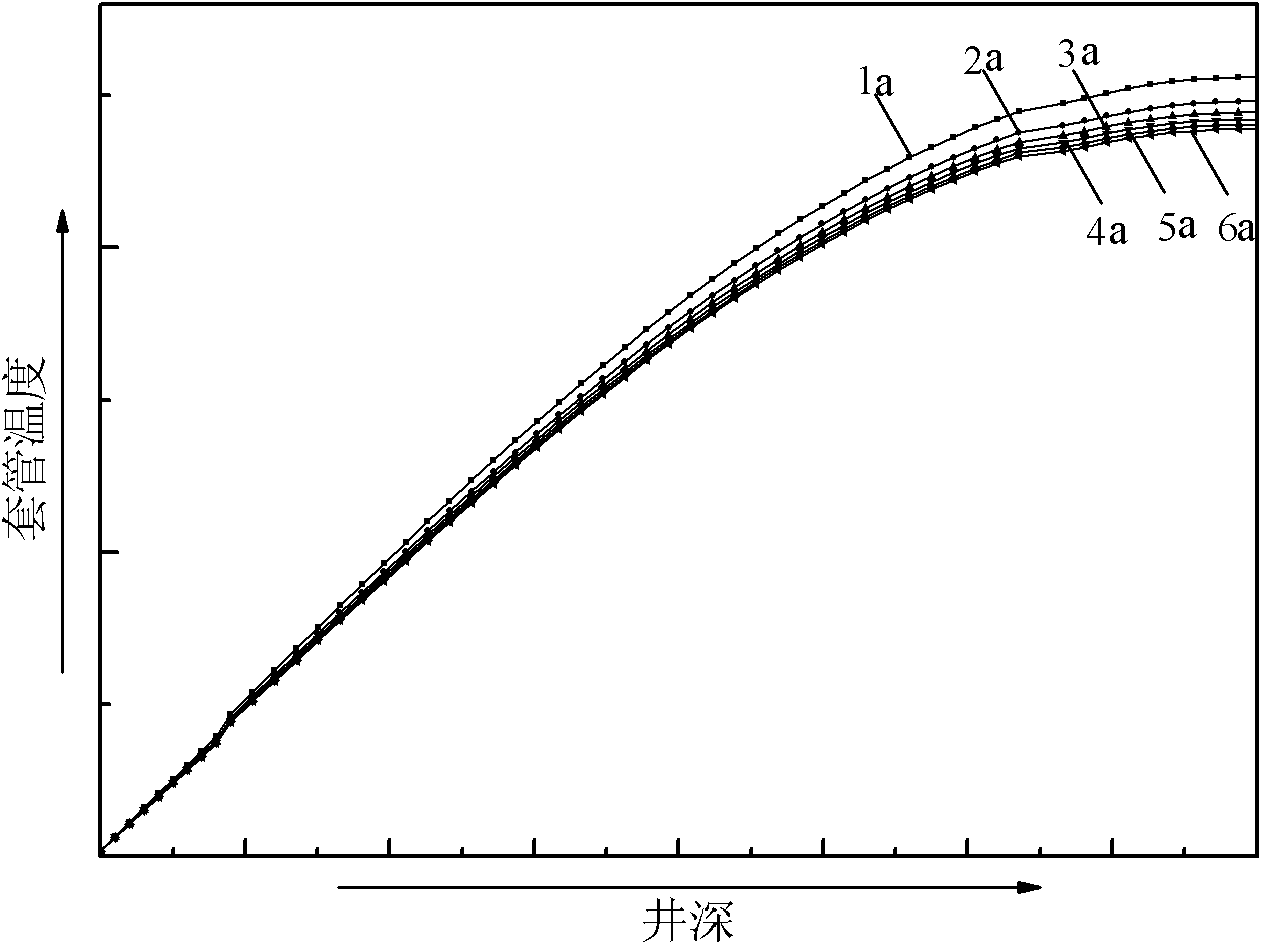

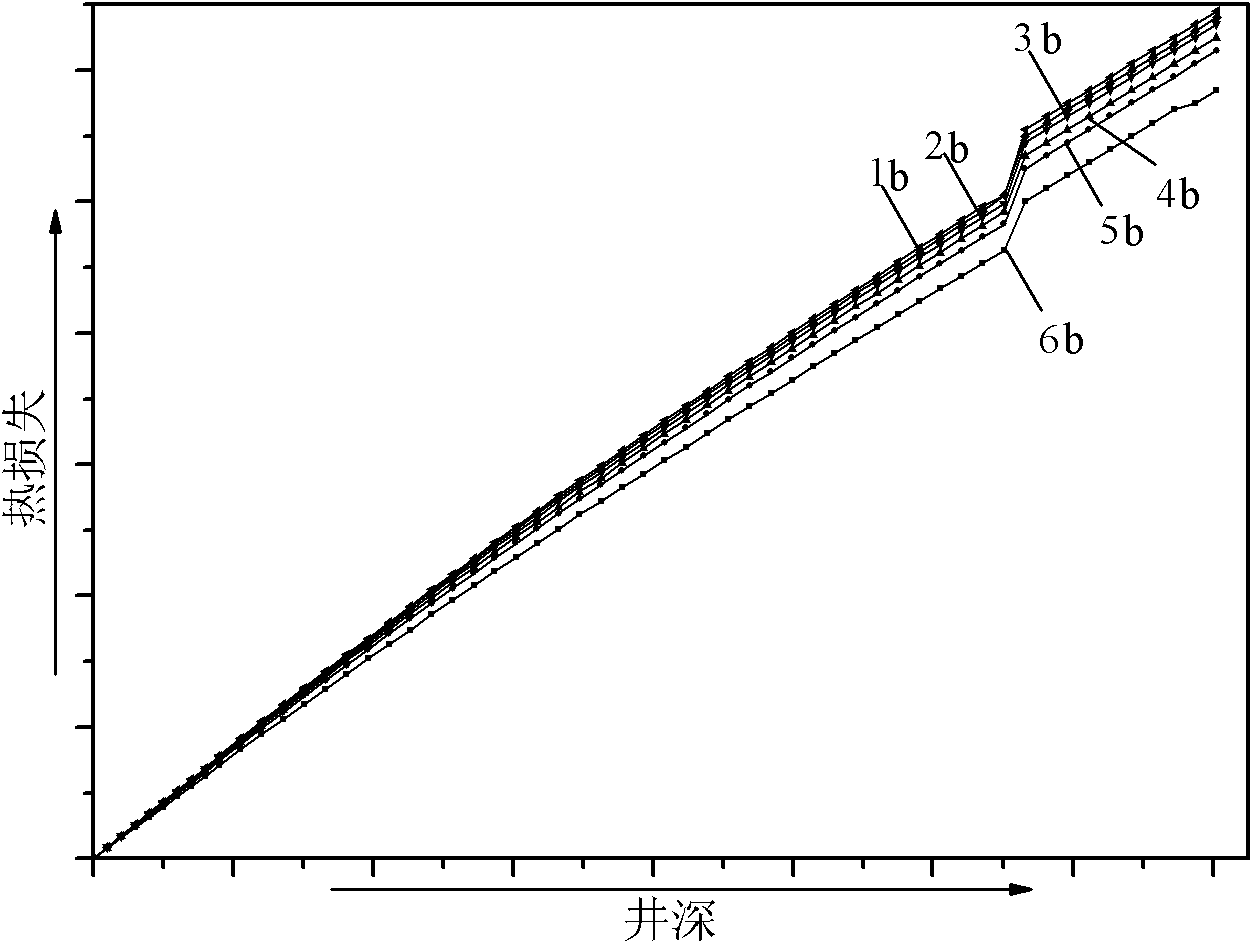

[0029] The present invention uses high-vacuum prestressed heat-insulated oil pipes as the main heat-insulation measure. When selecting insulated tubing, first select the insulation level of the insulated tubing according to the heat injection temperature, heat inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com