Family car exhaust manifold

A technology for exhaust manifolds and cars, which is applied to exhaust devices, air quality improvement, noise reduction devices, etc., can solve the problems of difficult processing, high equipment requirements, large factory investment, etc., and achieves easy processing, simple processing equipment, The effect of the simple structure of the parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

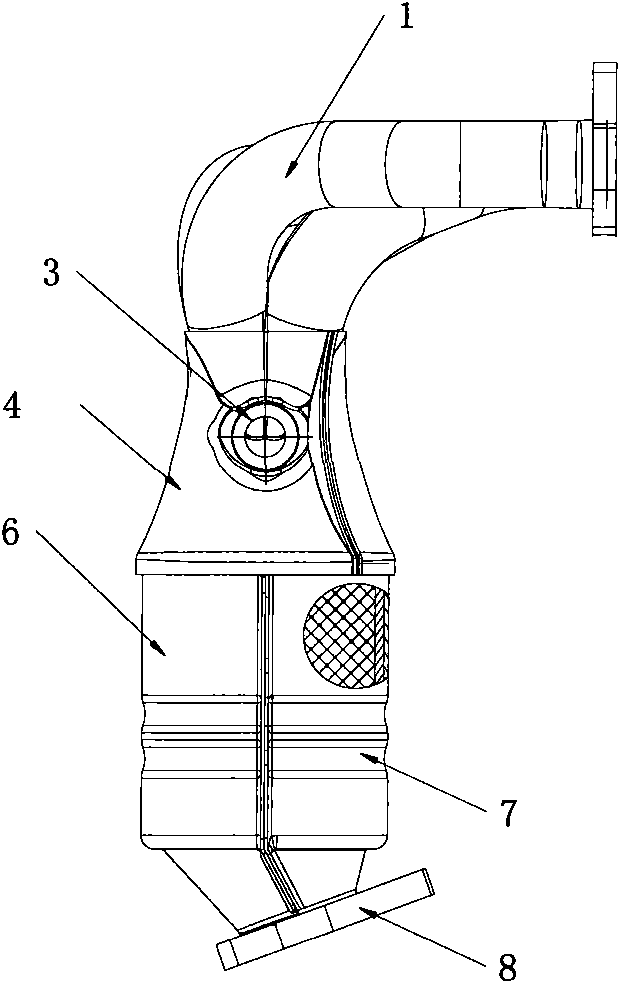

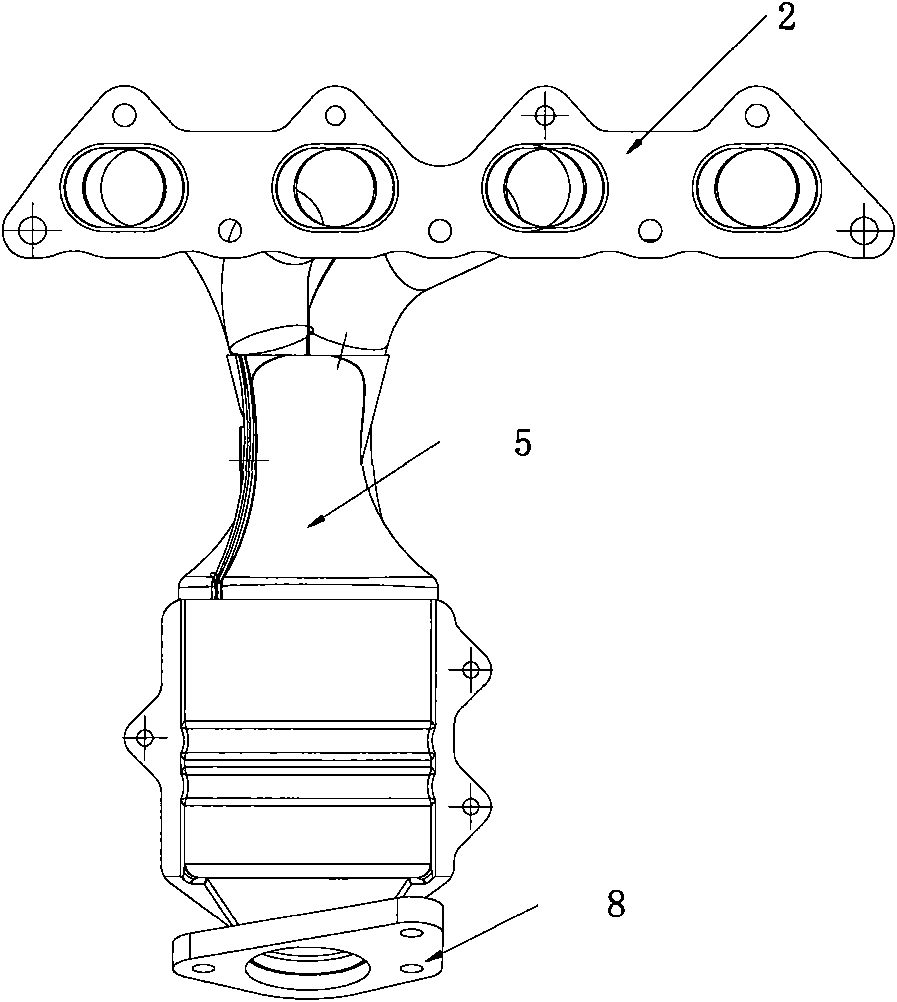

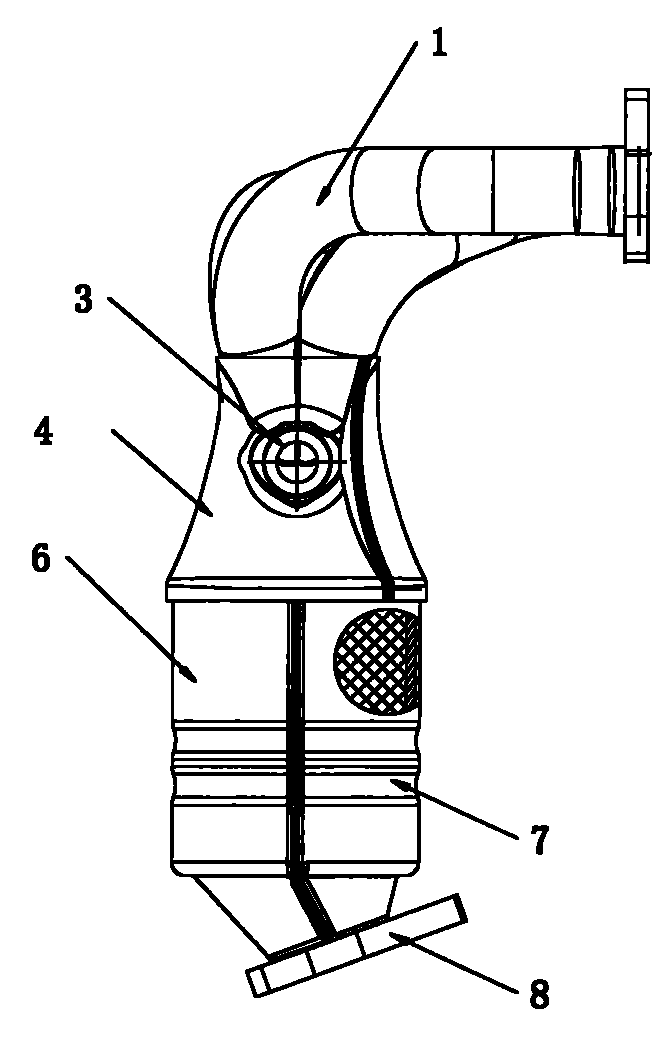

[0014] Such as figure 1 , 2 The shown exhaust manifold of a family car of the present invention comprises an intake pipe 1, a catalytic converter, and an outlet pipe; there are four intake pipes 1, and the downstream of the intake pipe 1 is connected with a catalytic converter, so The catalytic converter is provided with a catalyst; the downstream of the catalytic converter is connected with an air outlet pipe; the air intake pipe 1, the catalytic converter, and the air outlet pipe are independent and formed by welding; the catalytic converter includes a catalytic converter upper cover 14, Catalytic converter upper cover II 5, catalytic converter lower cover I 6, catalytic converter lower cover II 7; said catalytic converter upper cover I 4, catalytic converter upper cover II 5 butt welding; said catalytic converter lower cover I 6, catalytic converter The lower cover II 7 is butt welded; the cavity formed by the lower cover I 6 of the catalytic converter and the lower cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com