Intelligent constant-voltage high-precision leak detector

A leak detector, high-precision technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of the fluid, etc., can solve the problems of high clamping pressure, inability to eliminate, random errors, etc., to achieve The effect of eliminating theoretical errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

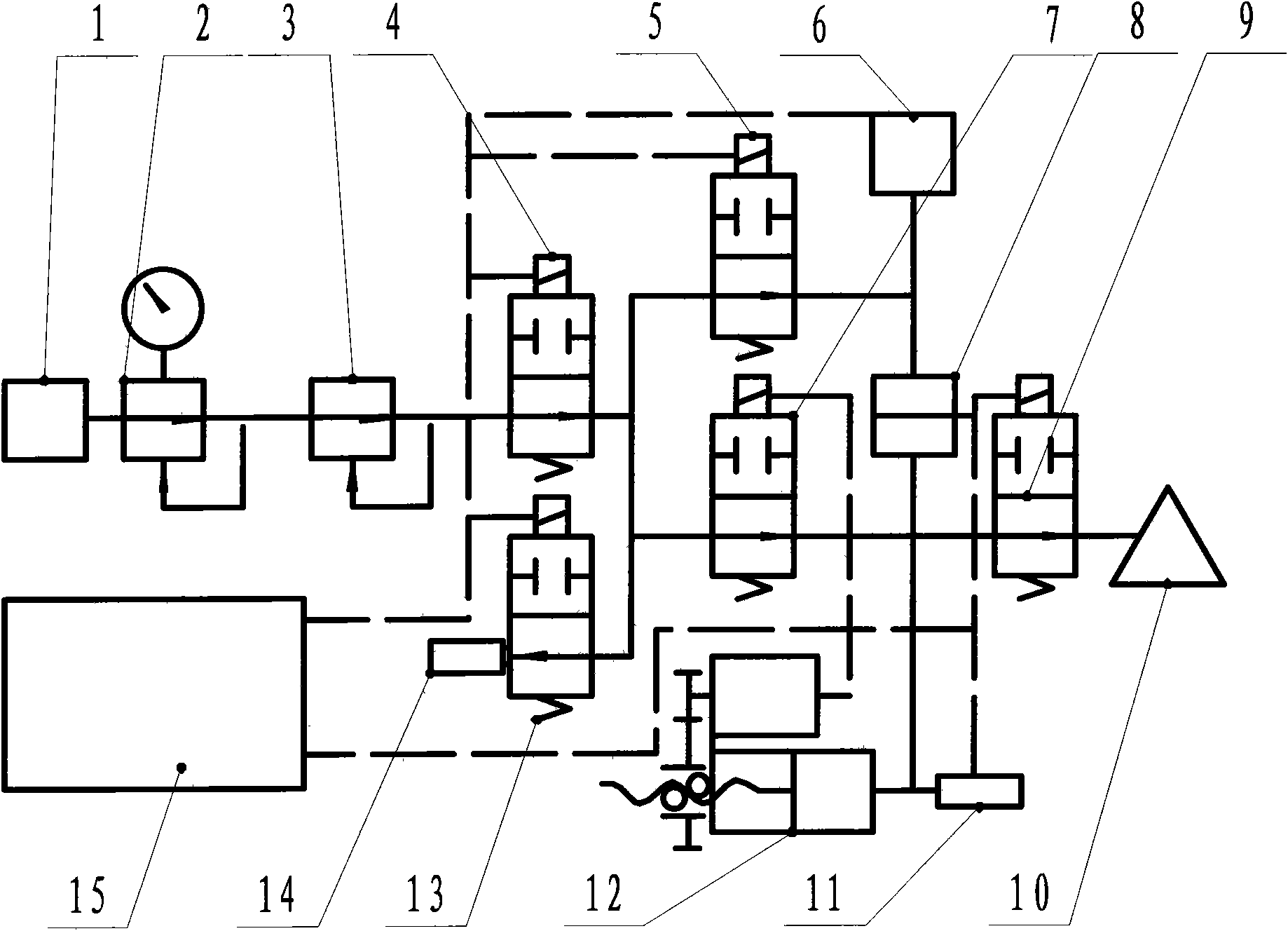

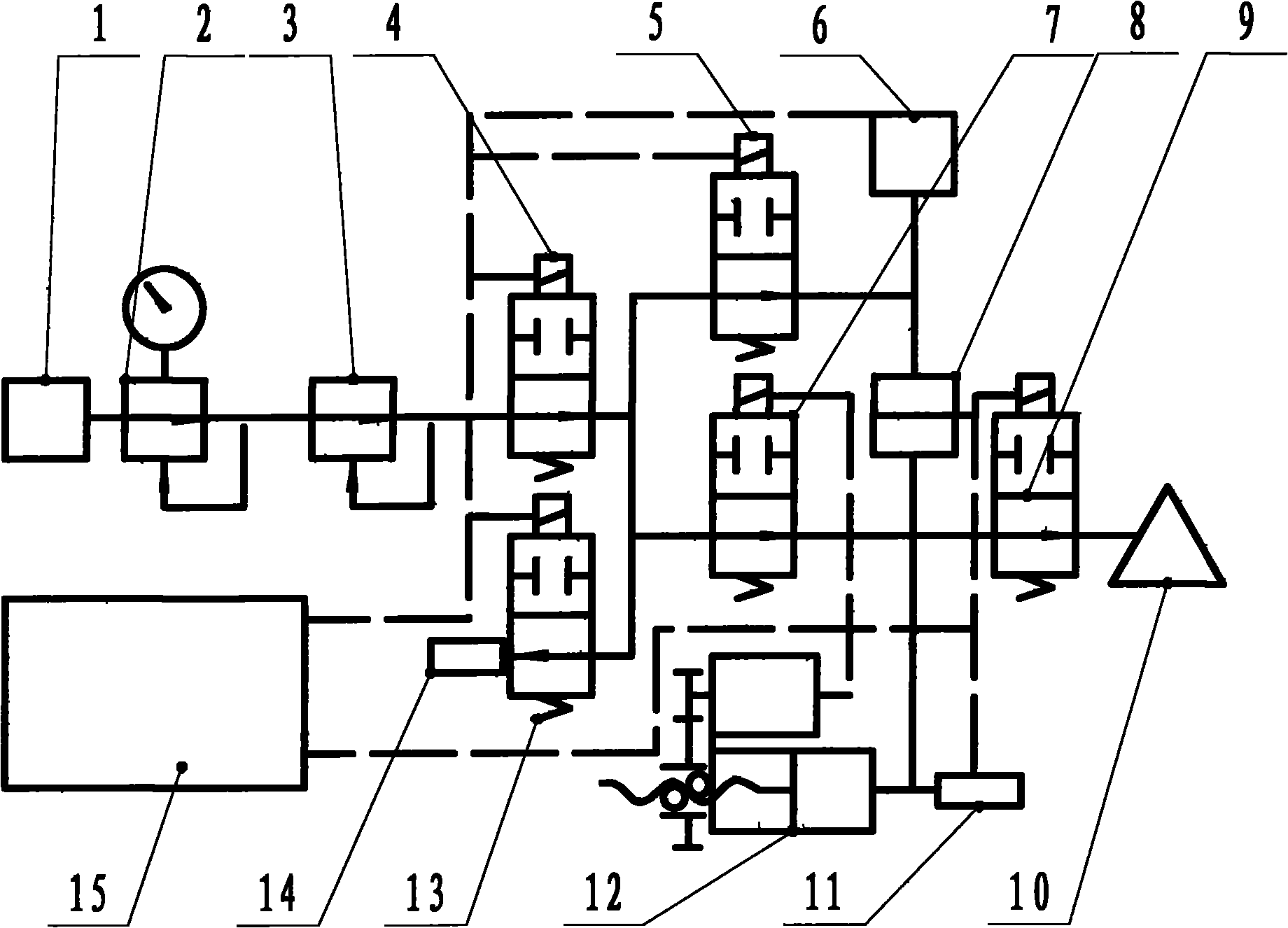

[0021] Combine below figure 1 , to describe a specific embodiment.

[0022] The compressed gas in the pressure gas source 1 in the figure is set by the pressure setting of the pressure regulating valve 2 to set the working pressure for the detection pressure regulating valve 3 . The detection pressure regulator valve 3 is used to control the gas pressure passing through the charging valve 4, that is, the system pressure of the detection system. When the system is started, the system first performs a self-test. During the self-test, the self-test valve 9 is closed, and the gas passage between the system and the device under test 10 is cut off, and then the inflation valve 4 is opened to fill the internal system with a test pressure regulator valve. 3 Set the pressure of the gas. After the inflation is completed, the inflation valve 4 is closed, and the electronic program controller 15 controls the servo barostat 12 to change according to the set value and the set number of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com