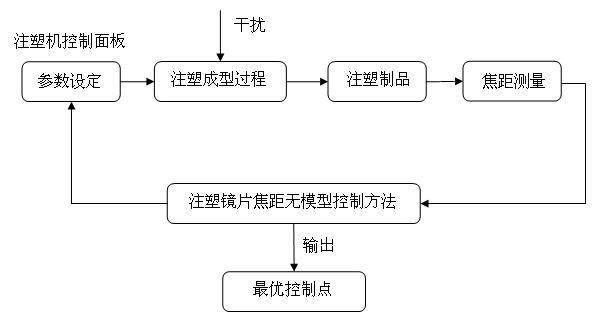

Model-free control method for focal distance of injection molded plastic lens

A control method, injection molding technology, applied to other household appliances, optical components, household appliances, etc., can solve the problems of process noise sensitivity, low work efficiency, poor gradient estimation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

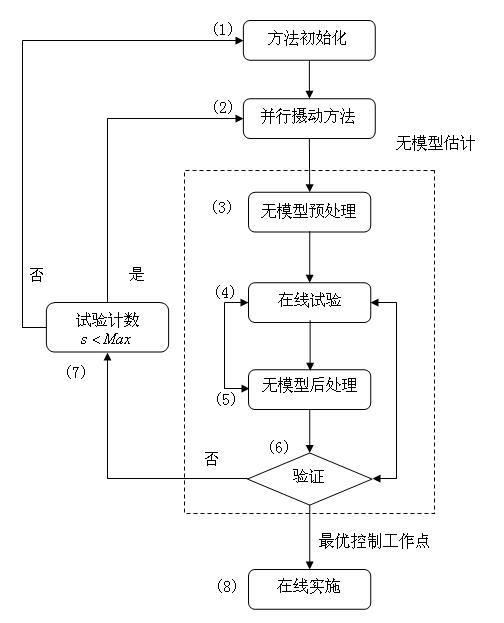

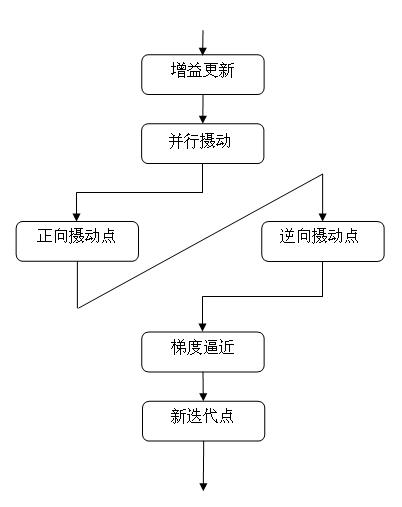

Method used

Image

Examples

Embodiment

[0053] The implementation process of the model-free control method for the focal length of an injection molded lens is illustrated below by taking the focal length control of a plastic magnifying glass lens as an example.

[0054]First, the method is initialized through step (1); the focal length of the lens controls the target =90 mm, according to the focal length noise fluctuation of the lens and the focal length tolerance of the lens, set the focal length target deviation tolerance mm, weight fluctuation variance tolerance mm, number of repetitions , the number of repeated measurements , the number of validation trials , the maximum number of trials , the parallel perturbation algorithm coefficient ; Select the process parameters that need to be optimized: injection pressure, holding pressure and holding time, in which the injection section is divided into one section and two sections to be controlled respectively, and the subsection point is also a key process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com