Reciprocating piece for crank round slider mechanism, and internal combustion engine and compressor thereof

A crank circular slider, reciprocating motion technology, applied in the fields of compressors, reciprocating moving parts, and internal combustion engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

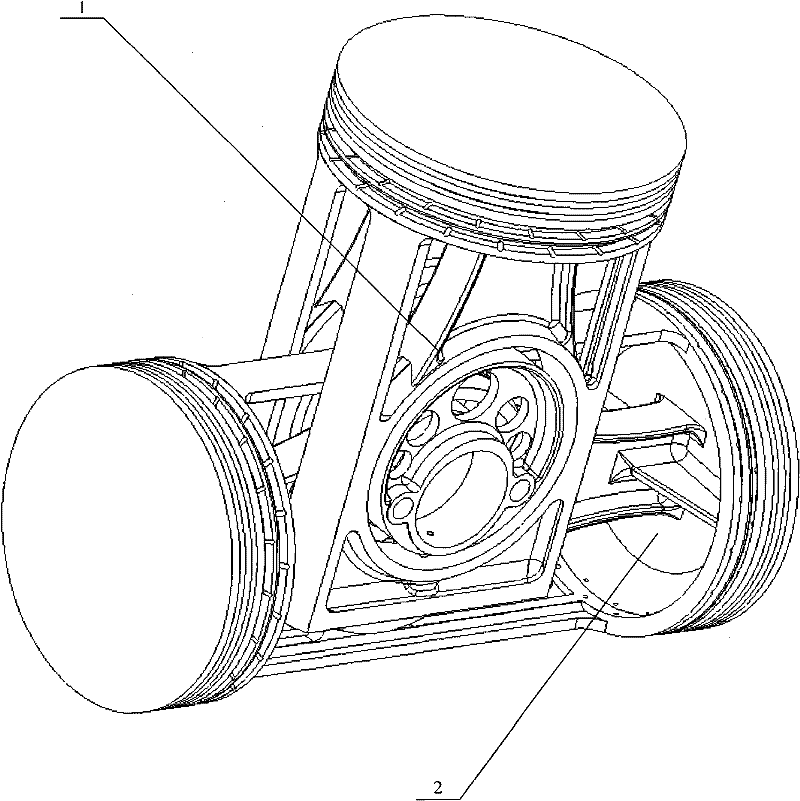

[0027] Please see image 3 , which is a layout diagram of the crank linkage mechanism used by the reciprocating member provided by the embodiment of the present invention. The reciprocating member provided in this embodiment is specifically a piston, image 3 It shows the arrangement structure of the moving parts when the piston is used in a T-shaped three-cylinder crank and slider engine.

[0028] Such as image 3 As shown, the mechanism mainly includes a single-acting piston 1 and a double-acting piston 2 . The two are respectively arranged on reciprocating orbits perpendicular to each other. The single-acting piston 1 moves up and down in the vertical direction, and the double-acting piston 2 moves left and right in the horizontal direction.

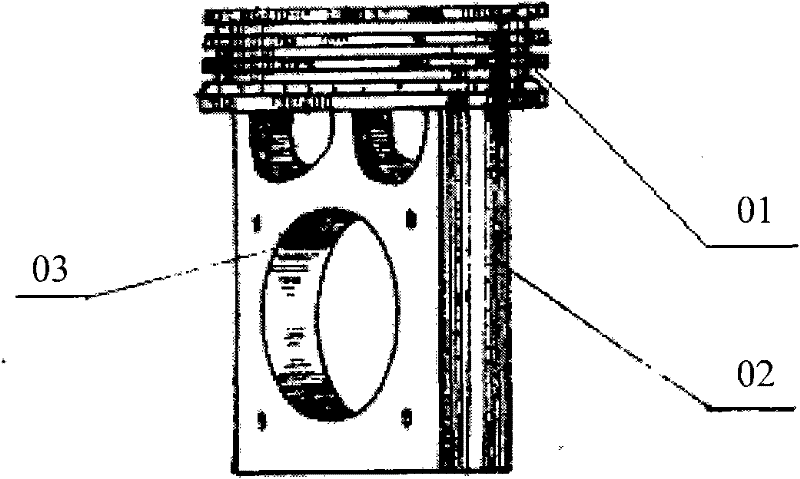

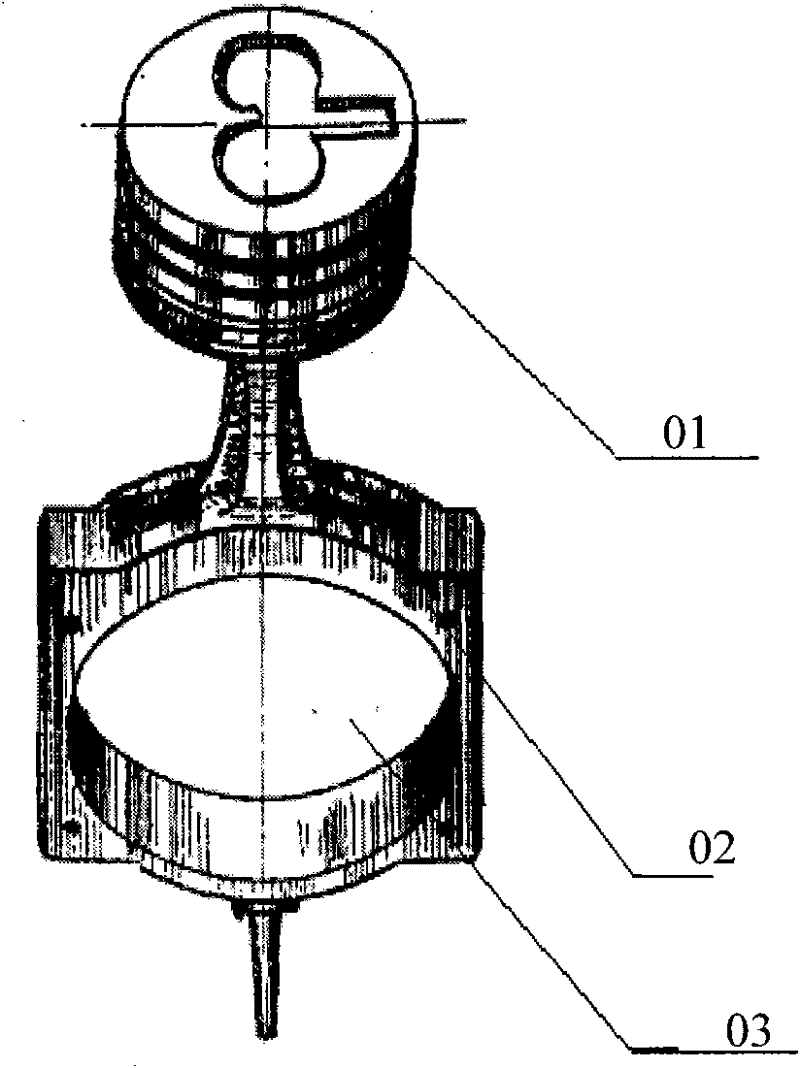

[0029] The single-acting piston 1 will be described in detail below. Please see Figure 4 , which shows a perspective view of a reciprocating member used in a crank-slider mechanism provided by an embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com