Bearing ring forging synchronous transmission support mechanical arm

A technology of synchronous transmission and bearing ring, which is applied in the field of casting and forging, and can solve the problems of high price and limited space of the working site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

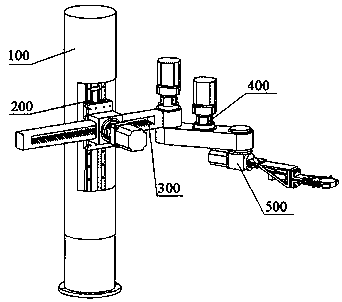

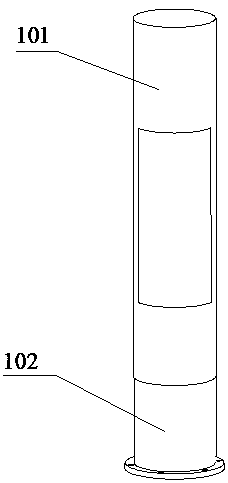

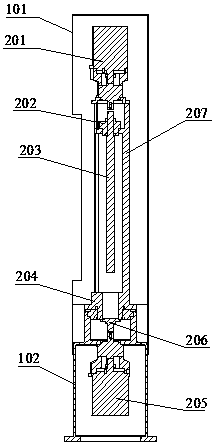

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the bearing ring forging clamps the manipulator, the fixed base 102 is fixed on the ground by bolts, the column 207 is fixed on the fixed base 102 by bolts, the column rotating motor 205 is fixed on the bottom of the fixed base 102 by bolts, and the two ends of the column drive shaft 206 are Connect with column rotating motor 205 and column 207 respectively, make column rotating motor 205 drive column 207 to rotate, lead screw motor 201 is fixed on the top of column 207 by bolt, screw lever 203 is fixed by column top cover 1 202, slide guide rail 208 is fixed on column 207 outside the open slot, the slider base 209 is installed on the sliding guide rail 208, slides up and down through the lead screw, the gear motor fixing base 210 is welded on the slider base 209, and the rack arm 301 passes through the gear motor fixing base 210, the gear motor 303 is fixed on the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com