Crank-slider mechanism, parts and equipment

A technology of crank round slider and round slider, which is used in mechanical equipment, variable displacement engines, machines/engines, etc., to improve stiffness and strength, improve motion balance, and complete motion balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

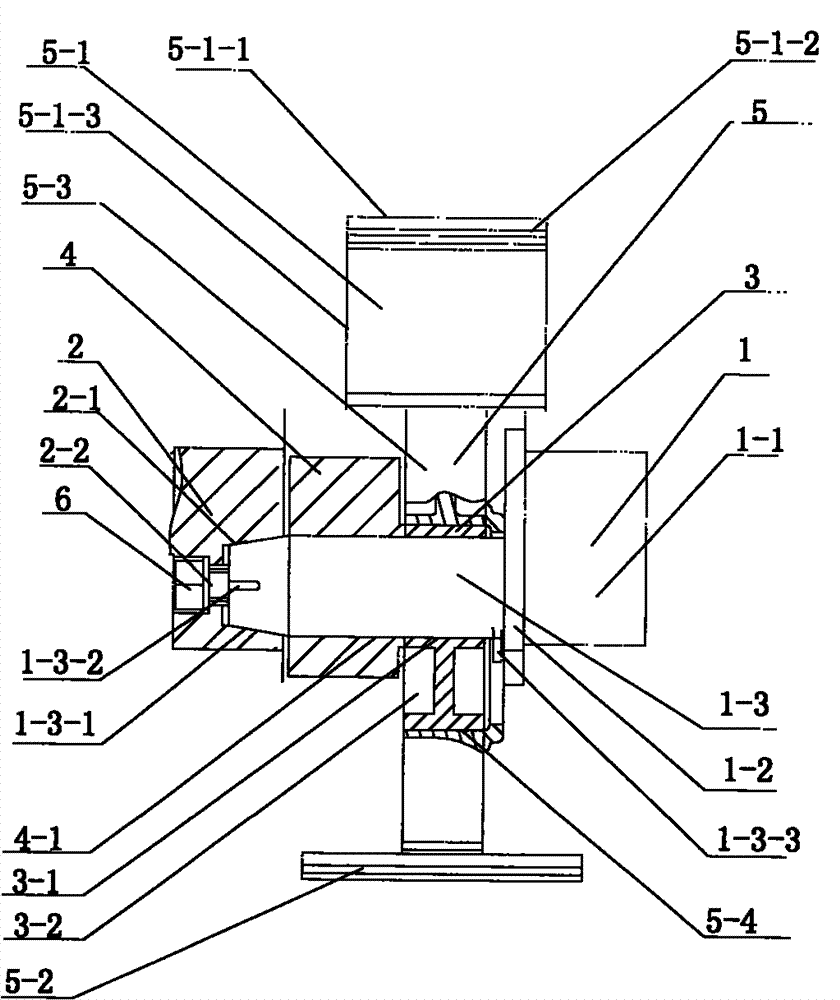

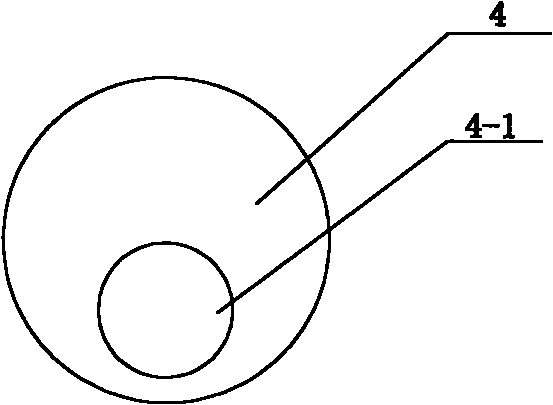

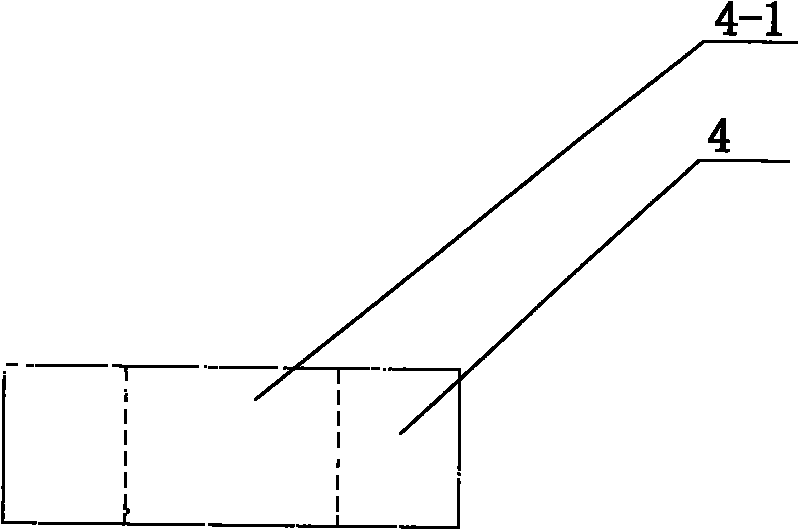

[0026] figure 1 It is a schematic structural diagram of the motion mechanism part of a crank-slider reciprocating piston internal combustion engine provided by the first embodiment of the present invention, that is, the crank-slider mechanism. It can be seen from this figure that the main moving parts of the crank circular slider mechanism inside the internal combustion engine and their interrelationships. In order to illustrate some specific parts, some positions in this figure are partially cut. Please see also figure 2 and image 3 , figure 2 Shows the front view of the dynamic balance block used in this mechanism; image 3 A top view of the dynamic balancing swivel is shown.

[0027] The internal combustion engine is a two-stroke diesel engine with a differential piston, which is reflected in figure 1 In the shown kinematic mechanism, it can be seen that the piston 5 is a double-acting piston with two piston heads having different diameters. The following combina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com