Speed control method for numerical control multilayer leather cutting machine tool

A speed control and cutting technology, applied in the field of multi-layer leather CNC cutting machine tools, can solve the problems of low speed and efficiency optimization, large tool compensation error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]The present invention will be further described below in conjunction with the accompanying drawings.

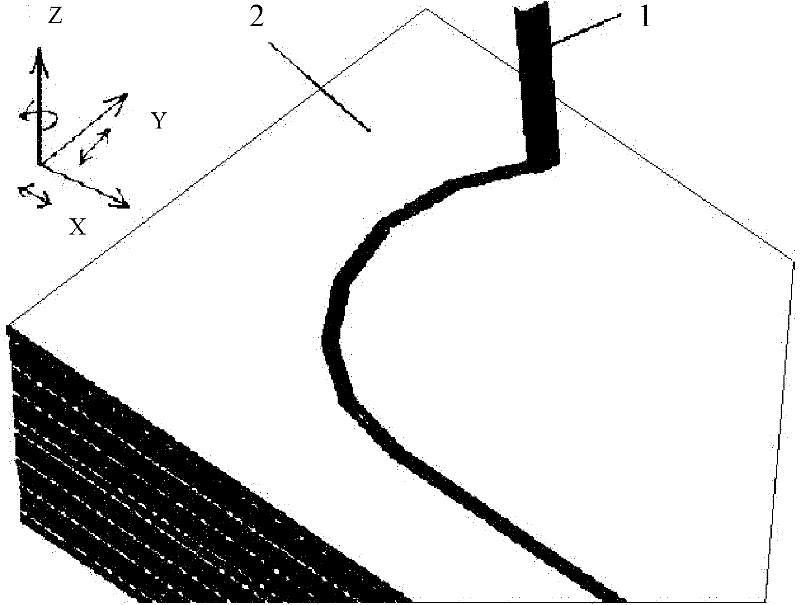

[0062] refer to figure 1 , a speed control method applied to multi-layer leather CNC cutting machine tools, figure 1 It is a schematic diagram of feed motion and tangential following motion. According to the figure, there are three major motions in the process of high-speed cutting of multi-layer leather: main motion—high-frequency vibration of sheet cutter 1 (Z direction), Complete the cutting movement of the multi-layer leather 2, and realize the cutting of the multi-layer leather 2 by the tool; feed movement-the plane movement (X, Y direction) of the cutting tool 1, and complete the cutting tool along the CAD layout track motion; auxiliary motion - the rotation of the sheet tool 1 during processing (Z Direction), that is, the tangential following movement, to complete the multi-layer leather 2. During the cutting process, the sheet cutter always keeps in line with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com