Tire cutter

A technology for cutting machines and tires, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of slow cutting speed, inconvenient detection, difficult to accurately locate the cutting position, etc., and achieve smooth and convenient axial section Accurate effect of detection and tire detection analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

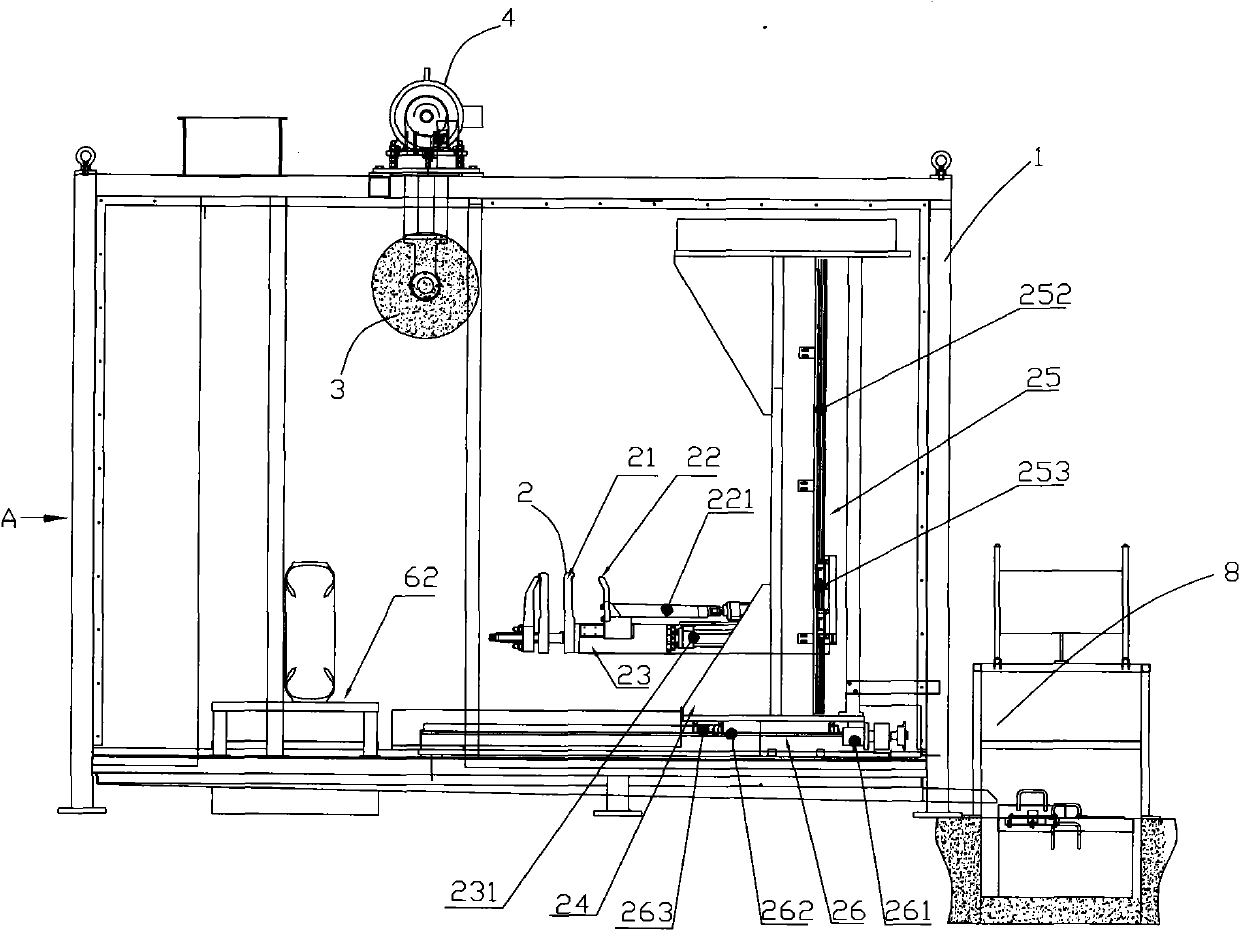

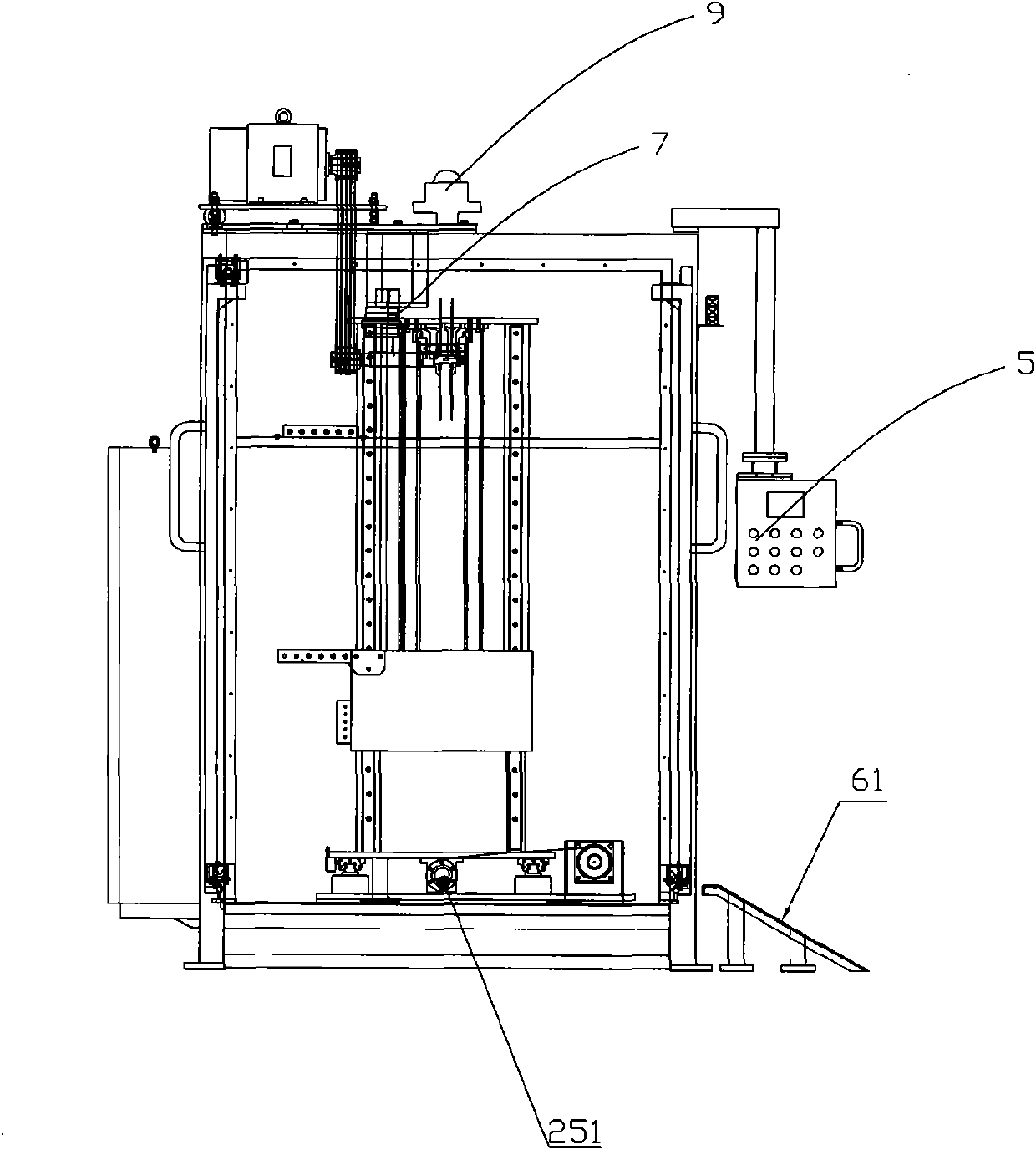

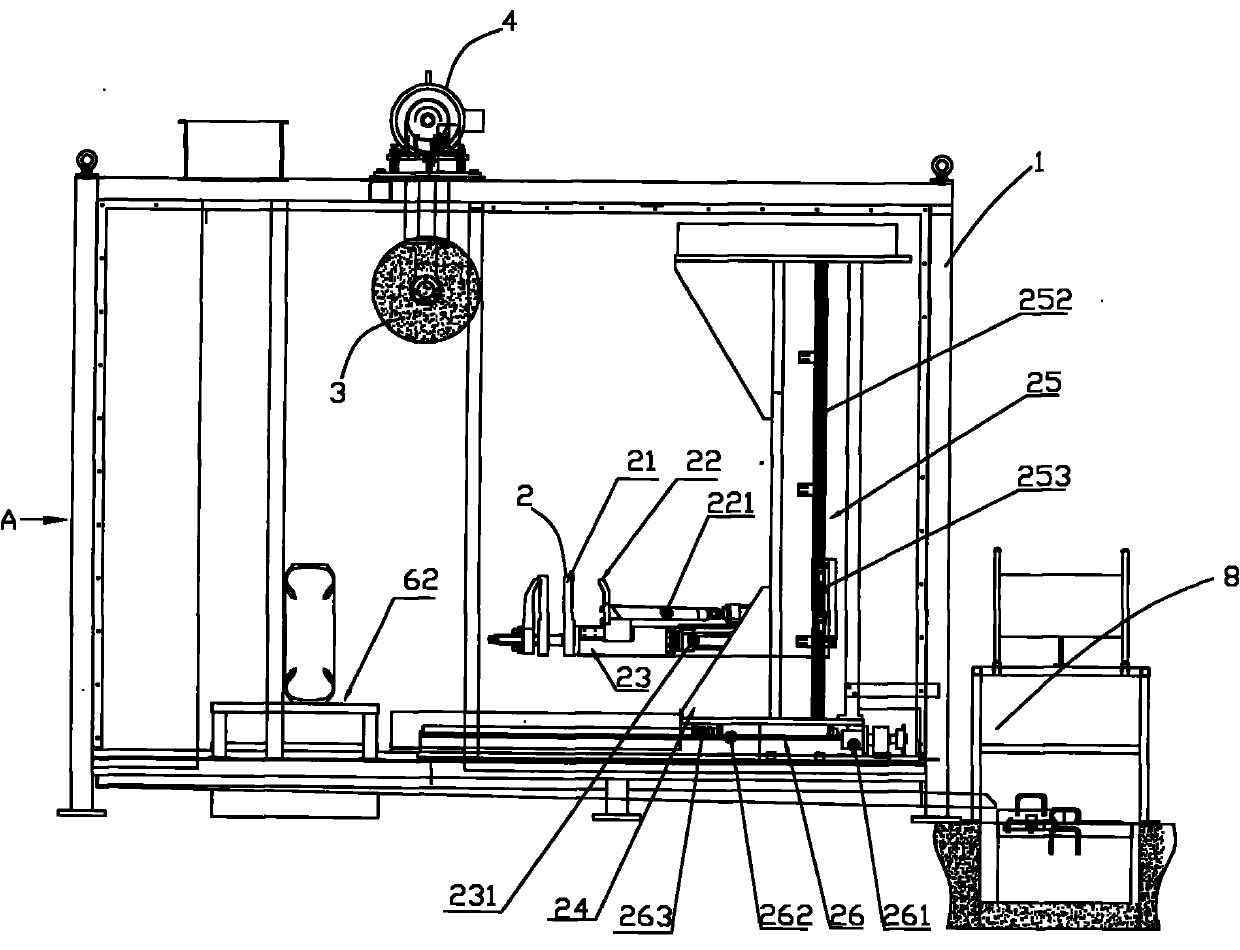

[0017] Embodiment: a tire cutting machine is characterized in that: it comprises a frame 1, a fixture 2, a cutting tool 3 and a cutting drive device 4, and based on the direction of use, the fixture 2 can be moved longitudinally and laterally on the side wall of the frame 1, The cutting tool 3 can be rotatably positioned at the lower end of the upper side wall of the frame 1 in the circumferential direction, and the cutting driving device 4 can drive the cutting tool 3 to rotate (the cutting driving device 4 can be an electric motor or a gasoline engine, a diesel engine, etc., this example is a servo motor, which is convenient to control ), the axial end face of the cutting tool 3 is parallel to the transverse feed direction of the fixture 2, the fixture 2 can fix the tire axially and radially, when in use, the tire is fixed and positioned in the fixture 2, the cutting tool 3 rotates at a high speed, and the fixture 2 carries the tire The tire is fed in the transverse and longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com