Air pressure type atomizing and ink-spraying marking device

An atomization spray and air pressure technology, applied in printing devices, typewriters, printing, etc., can solve the problems of lack of flexibility, bulky, unevenness, etc., and achieve the effect of flexible operation, uniform inkjet, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

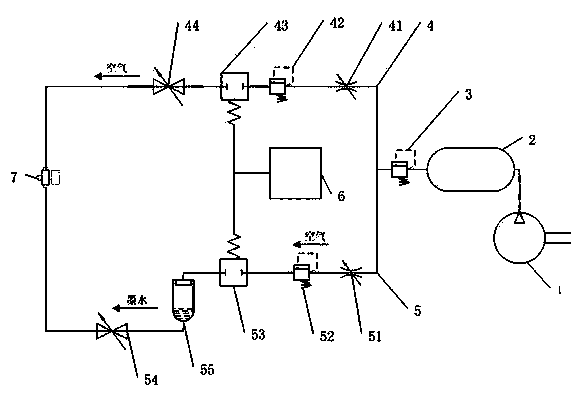

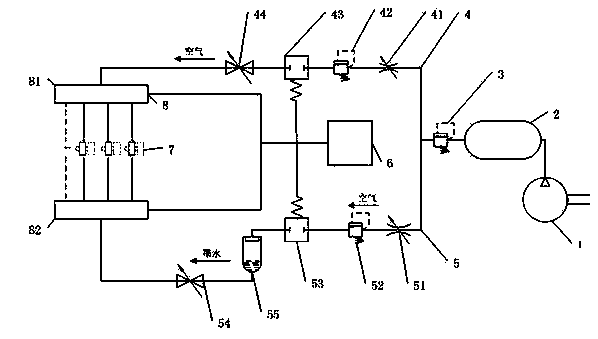

[0021] figure 1 As an embodiment of the present invention, the pneumatic atomization inkjet marking device of the present invention mainly includes an air compressor 1, an air storage tank 2, a mains pressure reducing valve 3, a gas delivery unit 4, a liquid delivery unit 5, an electrical Control unit 6 and atomizing nozzle 7. The gas generated by the air compressor 1 is buffered and stabilized by the air storage tank 2 to provide power for the liquid delivery and atomization of the device. The outlet of the gas storage tank 2 is provided with a main road pressure reducing valve 3 to adjust the air pressure of the main road. The marking liquid is transported to the atomizing nozzle 7, and the other way passes through the gas delivery unit 4 to the atomizing nozzle 7 to realize the atomization of the marking liquid.

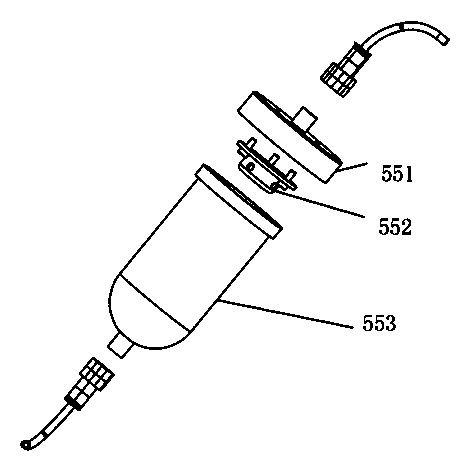

[0022] Such as figure 1 with image 3 As shown, the liquid delivery unit 5 includes a first throttle valve 51 , a first pressure reducing valve 52 , a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com