Ink-jet printing process and device based on high-density composite material multilayer substrate

A composite material, inkjet printing technology, applied in the direction of lamination device, printing device, printing, etc., can solve the problems of reduced service life, lack of laminated composite structure, etc., achieve uniform inkjet, ensure product quality, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

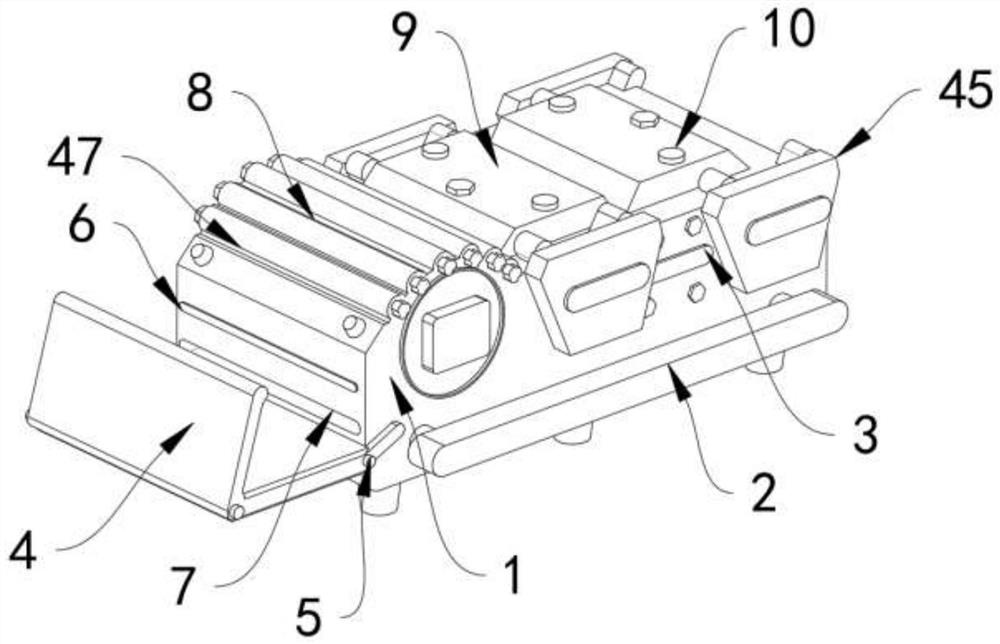

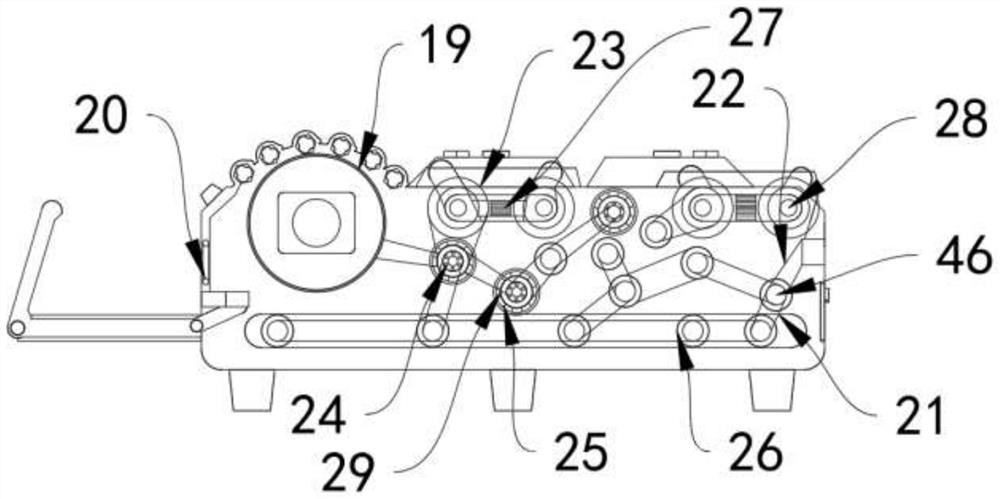

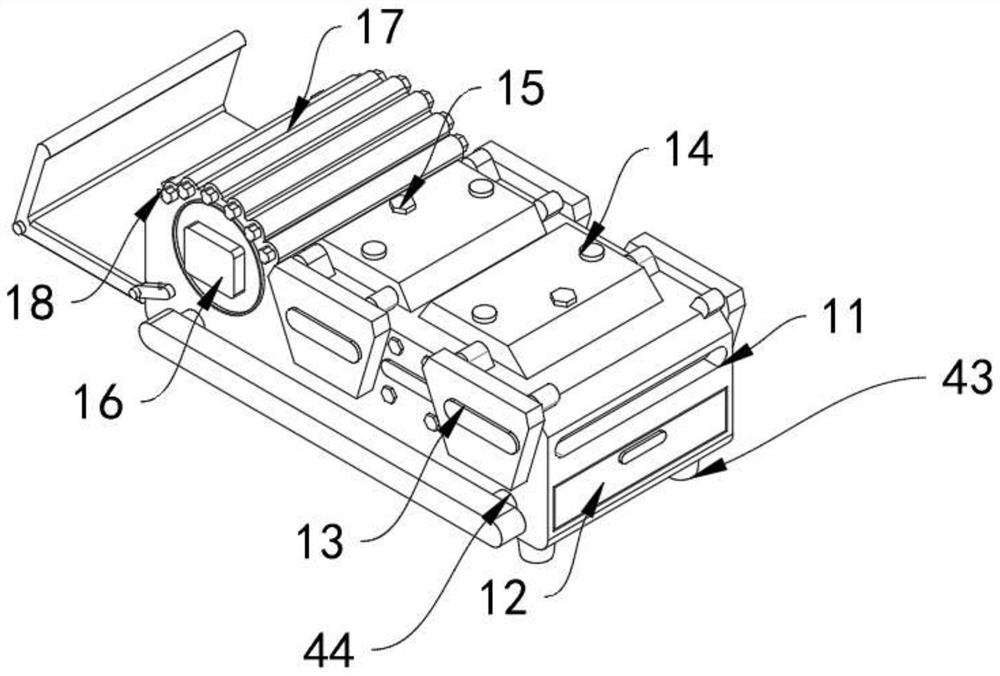

[0032] see Figure 1-5 , an embodiment provided by the present invention: an inkjet printing process based on a high-density composite multilayer substrate, comprising the following steps:

[0033]Step 1: First, place the printing box 1 in a suitable environment by the supporting frame 43, and according to the printing format and quantity requirements, transfer the parameters to the PLC master control display 3, and then rotate and adjust the holding stick 18, and then adjust the holding rod 18 accordingly. The roll cover 17 is opened, and different inks are injected into a plurality of ink filling tubes 47;

[0034] Step 2: Disassemble multiple dismantling plates 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com