Sliding rail system for refrigerator drawer

A sliding rail and drawer technology, which is applied to the sliding rail system field of drawers, can solve the problems of easy noise, limited bearing capacity, large space occupation, etc., and achieves the effects of increasing the usable space, reducing the bearing capacity, and increasing the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The structure of the refrigerator drawer slide rail system of the present invention will be described in detail below in conjunction with the drawings.

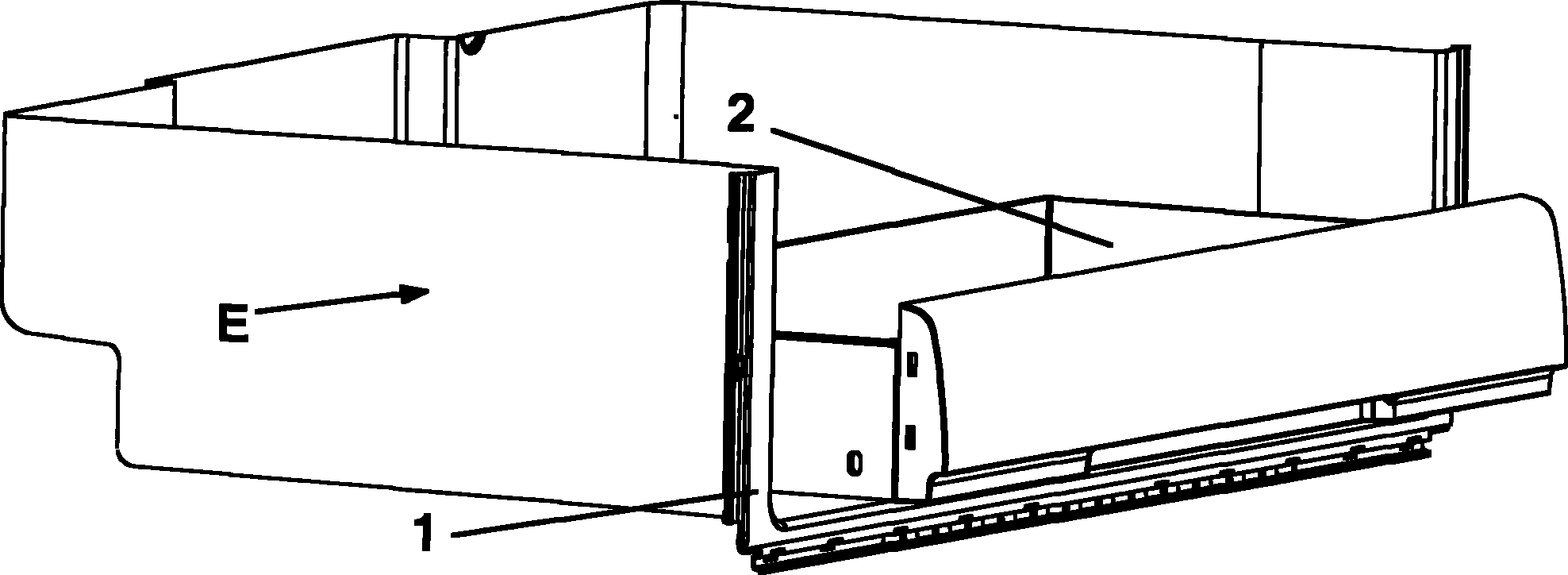

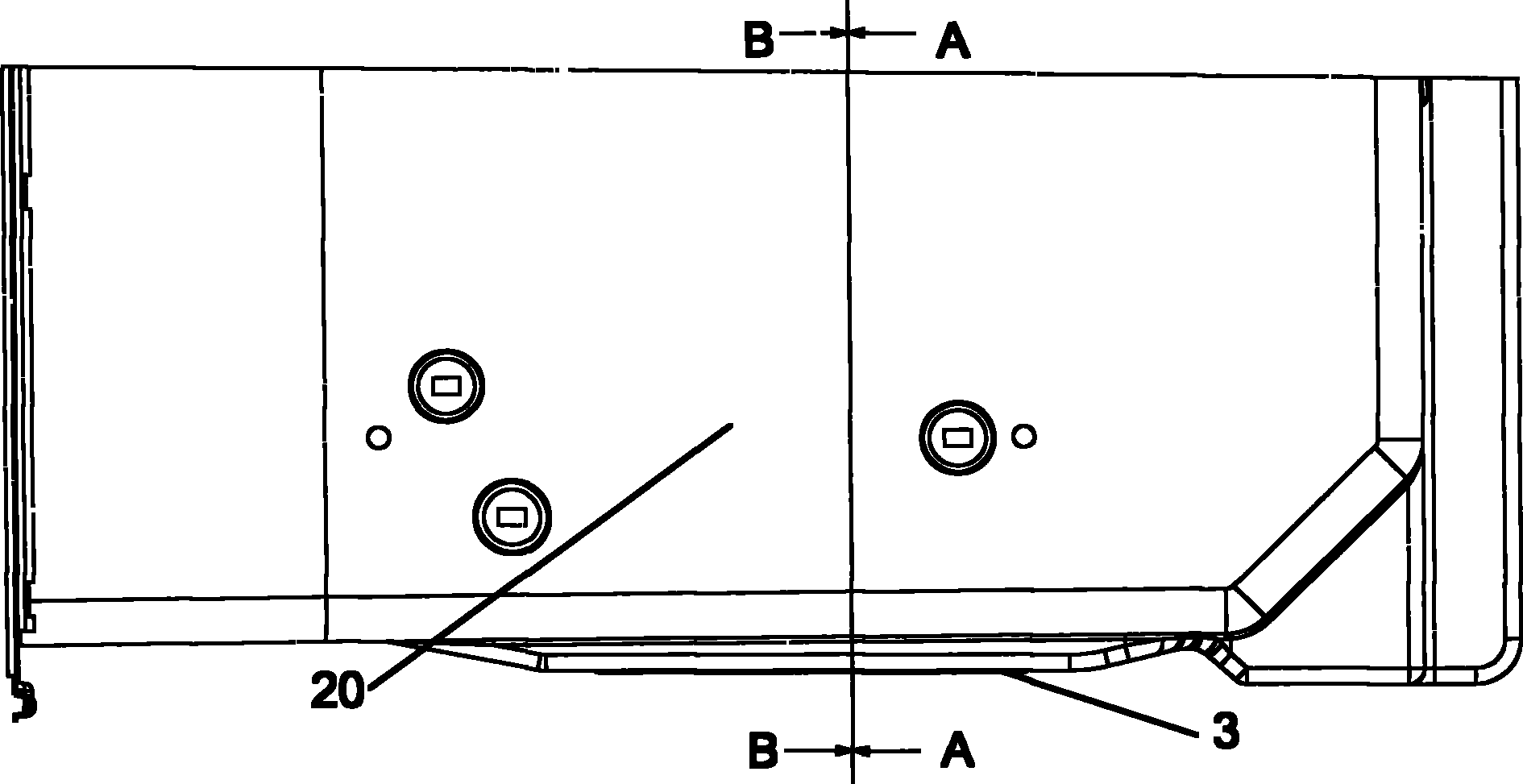

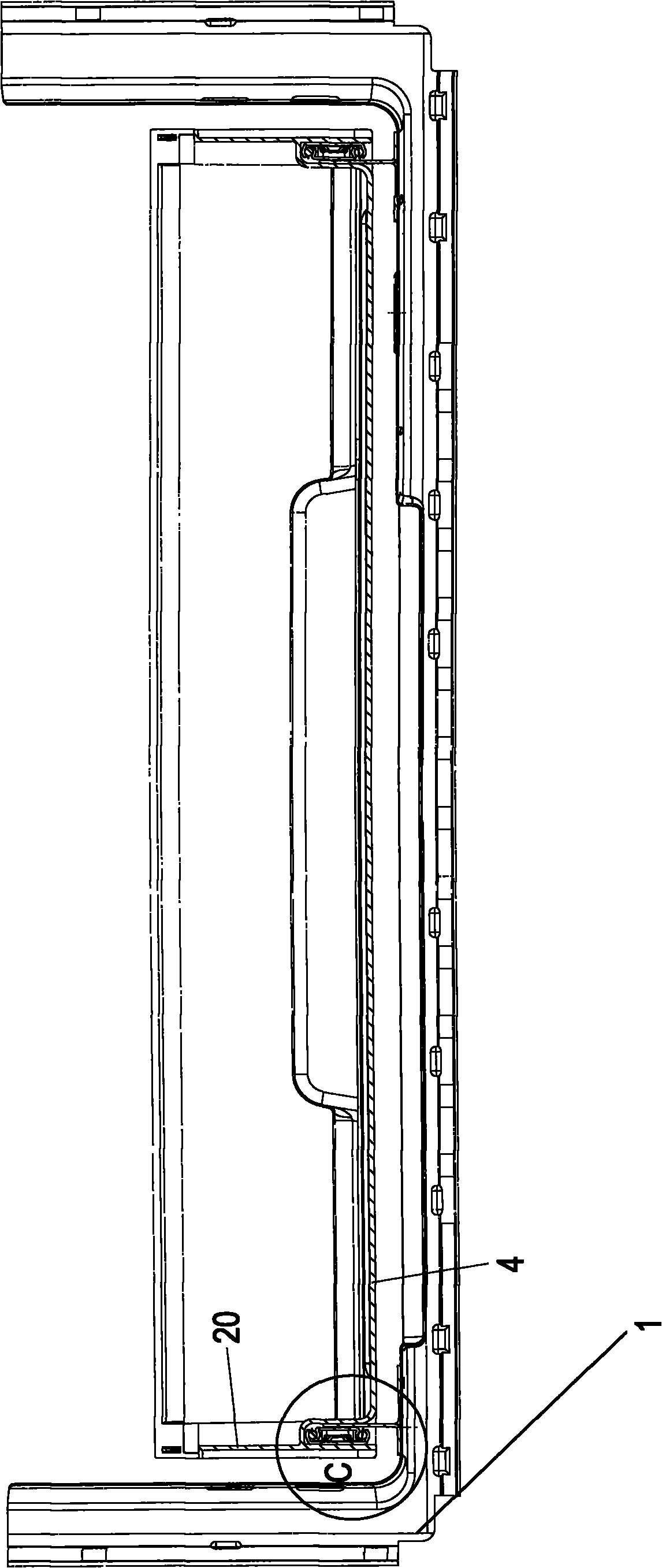

[0029] figure 1 For adopting the appearance diagram of the refrigerator drawer of the present invention, figure 2 for figure 1 View of the medium refrigerator drawer in direction E, from figure 1 with figure 2 It can be seen from the figure that the present invention provides a refrigerator drawer slide rail system, including a refrigerator drawer 2 and a refrigerator box 1 using the slide rail system. image 3 for figure 2 A cross-sectional view of the refrigerator drawer slide rail system of the present invention in the A-A direction, Figure 4 for image 3 The zoom-in view at C in the middle, from image 3 with Figure 4 It can be seen from the figure that the slide rail system is located at the bottom of the refrigerator drawer 2, and the bottom plate 4 of the refrigerator drawer 2 protrudes toward the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com